Are you gearing up for an interview for a Rotary Driller position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rotary Driller and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

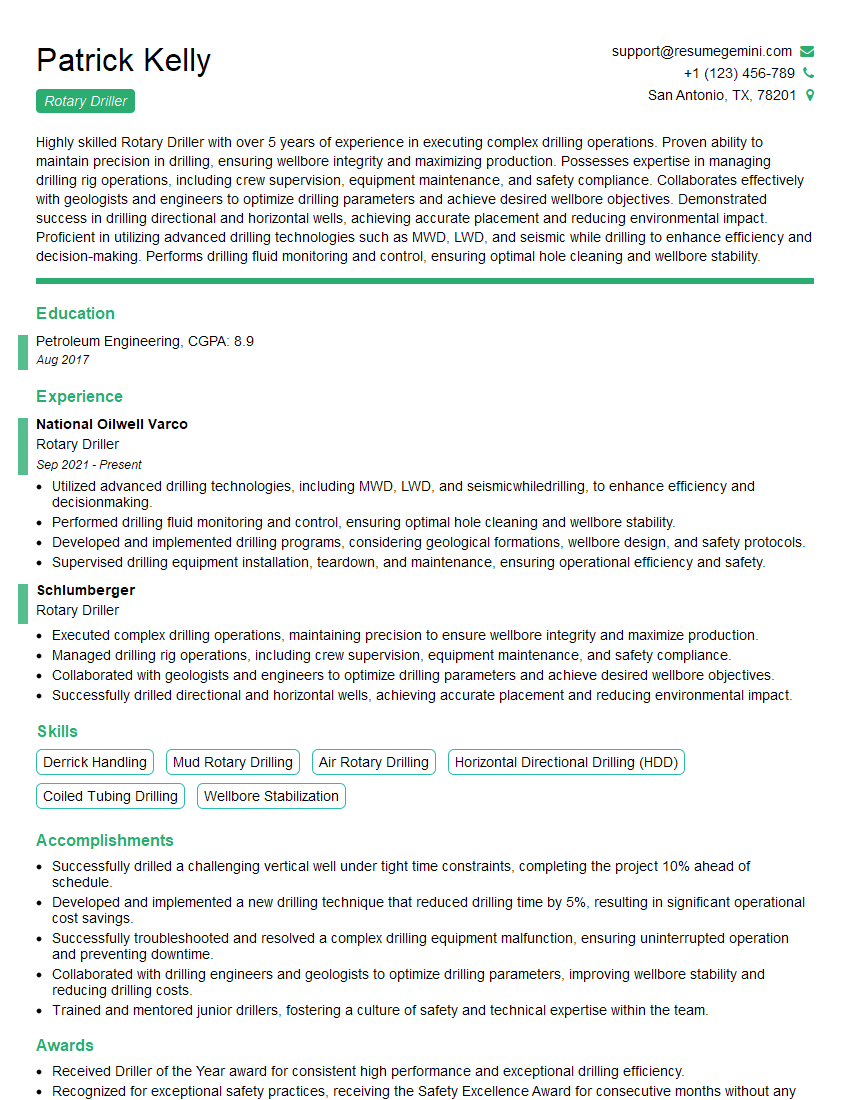

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotary Driller

1. Explain the key components of a rotary drilling rig and their functions?

- Mast: Supports the drill string and provides a platform for the crew to work.

- Drill String: Transmits power from the rig to the bit and removes cuttings from the hole.

- Drill Bit: Breaks up the formation and creates a borehole.

- Circulating System: Pumps drilling fluid to cool and lubricate the bit, remove cuttings, and support the hole.

- Power System: Provides power to the rig’s components.

- Control System: Monitors and controls drilling parameters such as depth, speed, and weight on bit.

2. Describe the different types of rotary drilling methods and their applications?

Top Drive Drilling

- Drill string is rotated from the surface using a top drive unit.

- Suitable for deep well drilling, directional drilling, and coiled tubing operations.

Rotary Table Drilling

- Drill string is rotated using a rotary table located at the surface.

- Used for shallower depths and less complex well conditions.

3. How do you calculate the weight on bit (WOB) and its significance in drilling operations?

- WOB = (Hook Load – Buoyancy Force) x Safety Factor

- WOB optimization is crucial for efficient drilling and borehole stability.

- Too low WOB can result in inefficient drilling, while too high WOB can damage the bit or formation.

4. Explain the role and selection criteria of drilling fluids?

- Functions of drilling fluids: Cooling and lubricating the bit, removing cuttings, maintaining borehole stability, and controlling formation pressure.

- Selection criteria: Compatibility with the formation, drilling conditions, availability, and cost.

- Types of drilling fluids: Water-based muds, oil-based muds, synthetic-based muds, and air/gas drilling fluids.

5. Describe the process of tripping in and tripping out of the hole?

-

Tripping In

- Connecting and running the drill string into the wellbore.

- Involves lowering individual drill pipes, making up connections, and pumping drilling fluid. Tripping Out

- Removing the drill string from the wellbore.

- Involves breaking down connections, pulling out drill pipes, and making up stands for storage.

6. How do you maintain a stable wellbore while drilling and prevent potential kick situations?

- Monitoring drilling parameters (WOB, RPM, flow rate, pressure) and adjusting as needed.

- Using blowout preventers (BOPs) to control formation pressure and prevent uncontrolled fluid flow.

- Proper wellbore design and casing programs to prevent hole instability.

7. Explain the importance of drill bit selection and how it impacts drilling performance?

- Bit selection depends on formation type, drilling conditions, and drilling objectives.

- Factors to consider: Bit type (roller cone, PDC, diamond), cutter size, number of cutters, and drilling rate.

- Proper bit selection can optimize drilling efficiency, minimize borehole damage, and reduce drilling costs.

8. Describe the principles of directional drilling and its applications?

- Directional drilling allows deviation from a vertical path to reach targets not accessible by vertical drilling.

- Uses steerable drilling tools (mud motors, rotary steerable systems) to control the drill string trajectory.

- Applications include access to offshore reservoirs, avoiding obstacles, and enhancing reservoir recovery.

9. How do you handle drilling emergencies such as a stuck drill string or a blowout?

- Stuck Drill String: Jarring, rotating, pulling, or using specialized tools to free the drill string.

- Blowout: Closing BOPs, activating the kill system, and notifying the necessary authorities.

10. Describe the role of mud logging in rotary drilling operations?

- Monitoring and analyzing drilling fluid samples to provide real-time information about formation characteristics.

- Identifies geological markers, hydrocarbon shows, and potential drilling hazards.

- Assists in making informed drilling decisions and optimizing drilling performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotary Driller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotary Driller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rotary Drillers play a crucial role in various industries, including oil and gas exploration, geotechnical engineering, and water well drilling. Here are the key responsibilities:

1. Drilling and Operation of Equipment

Operate and control rotary drilling rigs and associated equipment, ensuring smooth and efficient drilling operations.

- Follow drilling plans and specifications.

- Monitor drilling parameters and adjust settings accordingly.

2. Maintenance and Repair

Perform routine maintenance and repairs on drilling equipment and accessories.

- Inspect and lubricate components.

- Identify and resolve mechanical issues.

3. Safety and Environmental Compliance

Adhere to strict safety regulations and environmental standards.

- Wear appropriate personal protective equipment.

- Follow procedures to minimize environmental impact.

4. Collaboration and Communication

Work effectively as part of a team and communicate clearly with supervisors, colleagues, and clients.

- Provide regular updates on drilling progress.

- Coordinate with geologists and engineers.

5. Troubleshooting and Problem-Solving

Identify and resolve drilling-related issues in a timely and efficient manner.

- Analyze data and troubleshoot problems.

- Implement corrective actions to minimize downtime.

Interview Tips

1. Research the Company and Industry

Demonstrate your knowledge of the company and the industry by researching their operations, recent projects, and market trends.

- Visit the company’s website and social media pages.

- Read industry publications and attend conferences.

2. Highlight Your Experience and Skills

Emphasize your relevant experience in drilling operations, equipment maintenance, and safety protocols. Quantify your accomplishments with specific examples.

- Showcase your expertise in optimizing drilling parameters.

- Provide details of your contributions to successful drilling projects.

3. Prepare for Technical Questions

Anticipate technical questions about drilling techniques, equipment, and safety procedures. Review common industry jargon and prepare concise answers.

- Study drilling methods and best practices.

- Practice describing your troubleshooting and problem-solving abilities.

4. Practice Your Communication Skills

Interviewers value candidates who can communicate effectively. Practice articulating your thoughts clearly and concisely.

- Rehearse answering questions about your drilling experience.

- Prepare questions to ask the interviewer to show your engagement.

5. Dress Professionally and Be Punctual

Make a positive first impression by dressing professionally and arriving on time for the interview. Respect the interviewer’s time and demonstrate your punctuality.

- Wear appropriate attire for the industry and job position.

- Plan your transportation to avoid delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rotary Driller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!