Feeling lost in a sea of interview questions? Landed that dream interview for Rotary Dryer Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Rotary Dryer Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

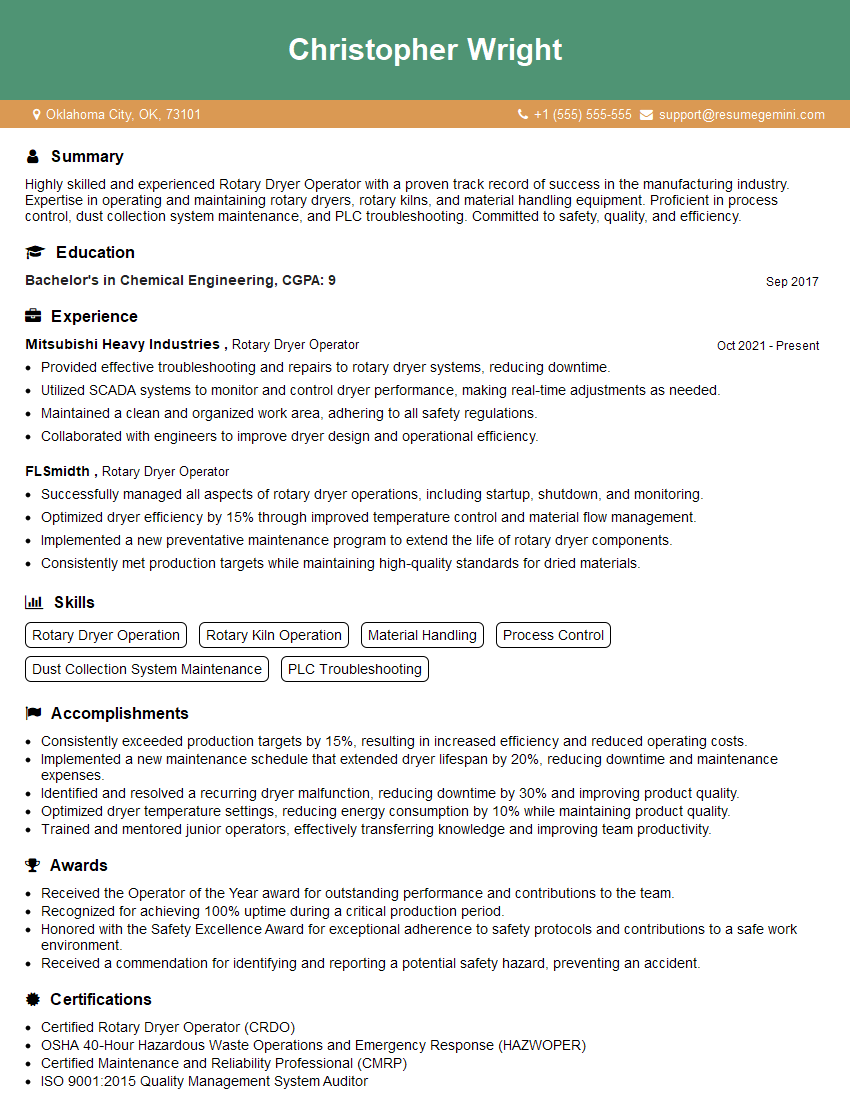

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotary Dryer Operator

1. Describe the primary responsibilities of a Rotary Dryer Operator?

The primary responsibilities of a Rotary Dryer Operator include:

- Operate and monitor rotary dryers to dry materials such as minerals, chemicals, and agricultural products

- Control temperature, flow rate, and other process parameters to ensure optimal drying conditions

- Inspect and maintain dryers, including lubrication, cleaning, and replacement of worn parts

- Monitor product quality and make adjustments as needed to meet specifications

- Troubleshoot and resolve problems with dryers and associated equipment

2. How do you maintain the temperature of the dryer to achieve the desired drying level?

Monitoring Temperature

- Utilize thermocouples or other temperature-sensing devices

- Monitor temperature readings regularly to ensure they align with target values

Adjusting Temperature

- Regulate fuel flow to the burner or heating element

- Control airflow through the dryer to influence heat transfer

- Adjust dryer speed to optimize material residence time and temperature exposure

3. Explain the importance of controlling flow rate in a rotary dryer?

Controlling flow rate in a rotary dryer is crucial for achieving efficient and consistent drying:

- Product Quality: Proper flow rate ensures uniform drying, preventing over-drying or under-drying of the material

- Energy Efficiency: Optimizing flow rate minimizes energy consumption by reducing the residence time of already-dried material in the dryer

- Equipment Longevity: Excessive flow rate can overload the dryer, leading to premature wear and tear of components

- Safety: Maintaining the appropriate flow rate prevents material buildup inside the dryer, reducing the risk of fires or explosions

4. How do you ensure that the product meets the required moisture content specifications?

To ensure that the product meets the required moisture content specifications, I follow these steps:

- Sample Collection: Collect representative samples of the dried material at regular intervals

- Moisture Analysis: Use moisture analyzers or other appropriate methods to determine the moisture content of the samples

- Data Analysis: Compare the measured moisture content to the specified limits

- Adjustments: If the moisture content is outside the acceptable range, make necessary adjustments to the dryer’s operating parameters, such as temperature, flow rate, or residence time

5. What are the common troubleshooting techniques used for rotary dryers?

When troubleshooting rotary dryers, I employ the following techniques:

- Visual Inspection: Examine the dryer for any visible issues, such as material buildup, leaks, or loose components

- Temperature and Flow Rate Checks: Verify that the temperature and flow rate settings are within the optimal range

- Product Quality Evaluation: Analyze the dried product to identify any deviations from specifications, such as uneven drying or excessive moisture

- Equipment Diagnostics: Utilize diagnostic tools to pinpoint any malfunctions in sensors, controllers, or other components

6. How do you prevent cross-contamination of different materials when using a rotary dryer for multiple products?

To prevent cross-contamination of different materials when using a rotary dryer for multiple products, I implement the following measures:

- Thorough Cleaning: Clean the dryer thoroughly between product changes, removing any residual material or debris

- Product Separation: Use dividers or baffles inside the dryer to separate different materials during the drying process

- Dedicated Equipment: If possible, allocate specific dryers to specific products to minimize the risk of cross-contamination

- Production Scheduling: Plan production schedules to avoid drying incompatible materials consecutively

7. Describe the safety precautions you take when operating a rotary dryer?

When operating a rotary dryer, I prioritize the following safety precautions:

- Personal Protective Equipment: Wear appropriate PPE, including gloves, safety glasses, and earplugs

- Area Security: Ensure the work area is clear of any hazards or obstructions

- Lockout/Tagout Procedures: Follow established lockout/tagout procedures before performing any maintenance or repairs

- Emergency Shutdown: Be familiar with emergency shutdown procedures and have access to emergency stop buttons

- Ventilation: Maintain adequate ventilation to prevent the accumulation of hazardous fumes or gases

8. How do you handle situations where the rotary dryer malfunctions or breaks down?

In the event of a rotary dryer malfunction or breakdown, I take the following steps:

- Immediate Shutdown: Shut down the dryer immediately to prevent further damage

- Safety First: Ensure the safety of myself and others before attempting any repairs

- Troubleshooting: Identify the potential cause of the malfunction using troubleshooting techniques

- Repairs: Perform repairs as necessary, following established procedures and safety guidelines

- Restart and Monitoring: Restart the dryer and closely monitor its operation to ensure it is functioning properly

9. What is the importance of regular maintenance for rotary dryers?

Regular maintenance for rotary dryers is crucial for ensuring:

- Optimal Performance: Regular maintenance helps maintain optimal operating conditions and efficiency

- Equipment Longevity: Proper maintenance extends the lifespan of the dryer and reduces the risk of costly repairs

- Safety: Regular inspections and maintenance minimize the risk of accidents or malfunctions

- Compliance: Maintenance records demonstrate compliance with industry regulations and safety standards

10. How do you stay updated with advancements and best practices in rotary dryer operations?

To stay updated with advancements and best practices in rotary dryer operations, I:

- Attend Industry Events: Participate in conferences and seminars to learn about new technologies and techniques

- Read Technical Publications: Stay informed through journals, white papers, and industry magazines

- Network with Peers: Connect with other rotary dryer operators and exchange knowledge and experiences

- Seek Training and Certification: Pursue training and certification programs to enhance my skills and stay abreast of industry standards

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotary Dryer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotary Dryer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rotary Dryer Operators are responsible for the safe and efficient operation, maintenance, and repair of rotary dryers used in industrial and manufacturing settings. Their key job responsibilities include:

1. Operation and Monitoring

• Operating rotary dryers to dry various materials, such as minerals, chemicals, and agricultural products

• Monitoring and adjusting operating parameters, such as temperature, feed rate, and air flow to ensure efficient drying

• Troubleshooting and resolving operational problems related to rotary dryers

2. Maintenance and Repair

• Performing routine maintenance tasks, such as lubrication, cleaning, and inspection of rotary dryers

• Conducting periodic inspections and repairs to ensure the safety and reliability of equipment

• Following maintenance schedules and reporting any issues or concerns to supervisors

3. Safety and Environmental Compliance

• Complying with safety regulations and procedures related to the operation and maintenance of rotary dryers

• Monitoring and controlling emissions and waste produced by rotary dryers to meet environmental standards

• Implementing and maintaining a clean and organized work environment

4. Communication and Teamwork

• Communicating with supervisors, engineers, and other plant personnel to report on operations and maintenance activities

• Working effectively as part of a team to achieve production and maintenance goals

• Providing training and support to other employees on rotary dryer operation and maintenance procedures

Interview Tips

To ace the interview for a Rotary Dryer Operator position, candidates should prepare thoroughly and highlight their relevant skills and experience. Here are some interview preparation tips:

1. Research the Company and Industry

Learn about the company’s history, products, services, and industry position. This demonstrates your interest in the company and the role.

2. Practice Answering Common Interview Questions

Prepare for questions about your experience operating and maintaining rotary dryers, as well as your safety and environmental knowledge. Practice answering these questions using the STAR method (Situation, Task, Action, Result):

Example Outline:- Situation: Briefly describe a specific situation or task.

- Task: Explain the task or action you took to address the situation.

- Action: Describe the specific actions you took to complete the task.

- Result: Highlight the positive outcomes or results of your actions.

3. Quantify Your Achievements

Use specific numbers and metrics to demonstrate your contributions and the impact of your work. For example, you could mention:

- Increased production output by a certain percentage

- Reduced downtime by optimizing maintenance procedures

4. Be Prepared to Discuss Safety and Environmental Compliance

Emphasize your commitment to safety and environmental regulations. Discuss any specific training or certifications you have in these areas.

5. Show Your Enthusiasm and Passion

Express your excitement about the opportunity to join the company and contribute to its success. Demonstrate your passion for operating and maintaining rotary dryers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rotary Dryer Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!