Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rotary Furnace Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

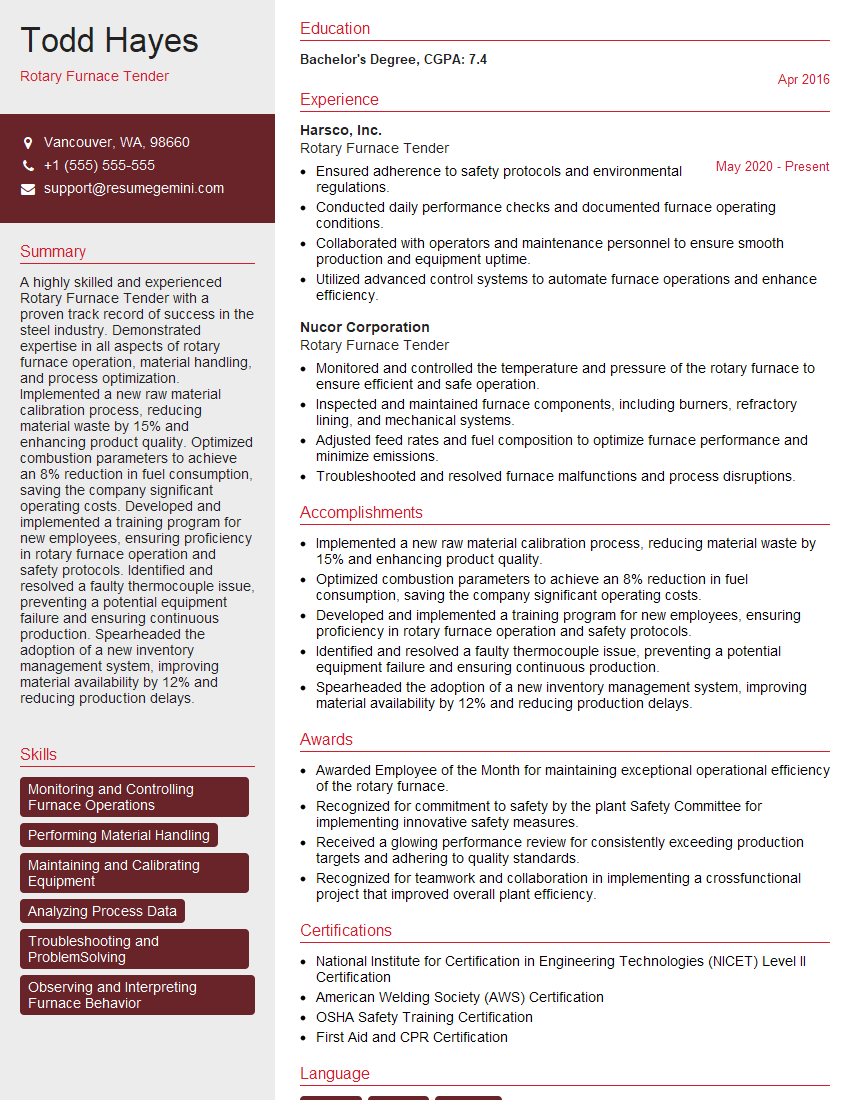

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotary Furnace Tender

1. Describe the key responsibilities of a Rotary Furnace Tender.

- Operate and monitor rotary furnaces to produce molten metal.

- Control and adjust furnace temperature, feed rates, and other process parameters.

- Monitor and maintain furnace equipment, including burners, conveyors, and dust collectors.

- Take samples of molten metal for quality analysis.

- Perform routine maintenance and repairs on furnaces.

2. How do you ensure the safe and efficient operation of a Rotary Furnace?

Safety Precautions

- Wear appropriate personal protective equipment (PPE).

- Follow established safety procedures and protocols.

- Identify and mitigate potential hazards.

- Maintain a clean and organized work area.

- Report any unsafe conditions or incidents immediately.

Efficient Operation

- Maintain optimal furnace temperature and feed rates.

- Monitor and control process parameters to achieve desired product quality.

- Conduct regular maintenance and inspections to ensure equipment reliability.

- Implement energy-efficient practices to reduce operating costs.

- Troubleshoot and resolve furnace malfunctions promptly.

3. What are the critical control parameters in Rotary Furnace operation?

- Feed rate (amount of material entering the furnace)

- Temperature (inside the furnace and molten metal)

- Furnace atmosphere (oxygen levels, reducing/oxidizing conditions)

- Burner operation (fuel type, air-to-fuel ratio)

- Molten metal composition (quality of final product)

4. Describe the maintenance procedures for the burners used in a Rotary Furnace.

- Inspect and clean burner nozzles regularly.

- Check and adjust gas flow and pressure.

- Lubricate moving parts.

- Replace worn or damaged components.

- Perform combustion efficiency tests.

5. How do you handle furnace emergencies, such as a flame failure or refractory damage?

- Follow established emergency procedures.

- Quickly identify and isolate the problem.

- Shut down the furnace safely and efficiently.

- Contact maintenance personnel for assistance.

- Document the incident and take corrective actions to prevent recurrence.

6. What is the role of refractories in Rotary Furnace operation?

- Protect the furnace lining from high temperatures and corrosion.

- Insulate the furnace to maintain heat.

- Provide a stable base for the molten metal.

- Prevent molten metal from reacting with the furnace structure.

7. How do you monitor and control the quality of molten metal produced in a Rotary Furnace?

- Take regular samples for chemical analysis.

- Use temperature probes to measure molten metal temperature.

- Observe the molten metal’s appearance and flow characteristics.

- Adjust furnace parameters to meet desired quality specifications.

8. What is the importance of controlling the atmosphere inside a Rotary Furnace?

- Prevents oxidation of molten metal.

- Controls the extent of chemical reactions occurring in the furnace.

- Ensures the production of high-quality metal.

- Minimizes furnace wear and tear.

9. Describe the different types of molten metal that can be produced in a Rotary Furnace.

- Iron

- Steel

- Copper

- Aluminum

- Nickel

10. What is your experience in working with molten metal handling equipment?

- Experience in operating casting machines.

- Experience in pouring and handling molten metal.

- Knowledge of safety precautions in molten metal handling.

- Understanding of different types of molten metal equipment.

- Ability to troubleshoot and maintain molten metal handling equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotary Furnace Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotary Furnace Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rotary Furnace Tender is a skilled professional responsible for operating and maintaining rotary furnaces, used for various industrial processes such as melting and heating materials. The primary goal of this role is to ensure safe, efficient, and productive furnace operations.

1. Furnace Operation

The Rotary Furnace Tender is responsible for operating the rotary furnace according to established procedures and safety protocols.

- Controlling and monitoring furnace temperature, speed, and other parameters

- Charging and discharging materials into and out of the furnace

2. Furnace Maintenance

The Rotary Furnace Tender performs regular inspections, maintenance, and repairs on the furnace and related equipment.

- Conducting visual and preventative maintenance inspections

- Replacing worn or damaged components

- Cleaning and lubricating furnace parts

3. Process Monitoring

The Rotary Furnace Tender monitors the furnace process, including material flow, product quality, and operating conditions.

- Identifying and adjusting process parameters to optimize performance

- Monitoring alarms and taking corrective actions as needed

- Maintaining production logs and records

4. Safety Compliance

The Rotary Furnace Tender upholds workplace safety regulations and follows established safety protocols.

- Wearing appropriate personal protective equipment

- Complying with all safety regulations and procedures

- Responding to emergencies promptly and effectively

Interview Tips

Preparing thoroughly for a Rotary Furnace Tender interview can significantly increase your chances of success. Here are some effective tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s background, products, and industry trends. This knowledge will demonstrate your interest and enthusiasm for the role.

- Review the company website, annual reports, and industry news

- Identify the company’s key competitors and their market position

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Tell me about your experience operating and maintaining rotary furnaces.

- Describe a time you identified and resolved a furnace problem.

- How do you ensure safety in a high-temperature work environment?

3. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job responsibilities. Provide specific examples to demonstrate your proficiency.

- Experience in furnace operation, maintenance, and repair

- Knowledge of furnace safety protocols and regulations

- Ability to work independently and as part of a team

4. Show Enthusiasm and Professionalism

Convey your enthusiasm for the role and the industry. Dress professionally, arrive on time, and maintain a positive attitude throughout the interview.

- Express your passion for working in the field

- Ask thoughtful questions to show your engagement

- Thank the interviewer for their time and consideration

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rotary Furnace Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!