Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Rotary Kiln Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Rotary Kiln Operator so you can tailor your answers to impress potential employers.

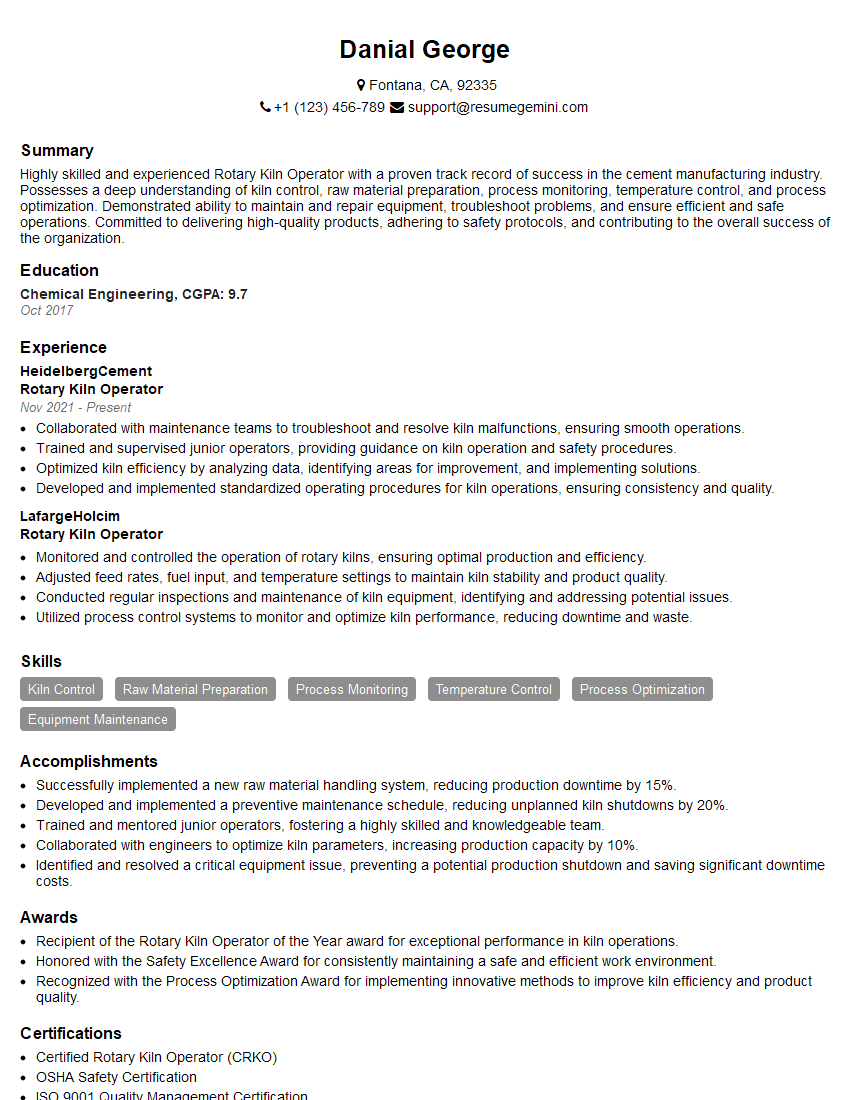

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotary Kiln Operator

1. Explain the process of feeding raw materials into the rotary kiln?

The feeding of raw materials into the rotary kiln is a critical step in the cement manufacturing process. The raw materials, which typically include limestone, clay, and other minerals, are first crushed and then ground into a fine powder. The powder is then mixed with water to form a slurry. The slurry is then fed into the rotary kiln through a feed pipe. The feed pipe is located at the end of the kiln, and the slurry is fed into the kiln in a continuous stream.

- The feed rate is controlled by a variable-speed drive.

- The feed rate is adjusted to maintain the desired temperature in the kiln.

2. How do you control the temperature in the rotary kiln?

Temperature Control Zones

- The temperature in the rotary kiln is controlled by a series of burners located along the length of the kiln.

- The burners are fired with natural gas or fuel oil.

Temperature Measurement

- The temperature in the kiln is measured by a series of thermocouples located along the length of the kiln.

- The thermocouples are connected to a temperature controller.

Temperature Control

- The temperature controller compares the measured temperature to the desired temperature.

- The temperature controller adjusts the firing rate of the burners to maintain the desired temperature.

3. What are the safety procedures that you must follow when operating a rotary kiln?

There are a number of safety procedures that must be followed when operating a rotary kiln. These procedures include:

- Wearing appropriate personal protective equipment (PPE), such as a hard hat, safety glasses, and gloves.

- Being aware of the location of all emergency exits.

- Knowing how to operate the emergency stop button.

- Never entering the kiln while it is in operation.

- Following all lockout/tagout procedures.

4. What are the maintenance tasks that you are responsible for as a rotary kiln operator?

As a rotary kiln operator, I am responsible for a number of maintenance tasks, including:

- Inspecting the kiln for any damage or wear.

- Lubricating the kiln bearings.

- Replacing the kiln lining.

- Calibrating the kiln temperature control system.

5. What are the quality control procedures that you follow to ensure that the cement produced by the rotary kiln meets specifications?

The quality of the cement produced by the rotary kiln is critical to the safety and performance of concrete structures. To ensure that the cement meets specifications, I follow a number of quality control procedures, including:

- Sampling the cement and testing it for compliance with ASTM standards.

- Monitoring the kiln operating parameters and making adjustments as necessary.

- Calibrating the kiln temperature control system.

6. What are the environmental regulations that you must comply with when operating a rotary kiln?

There are a number of environmental regulations that I must comply with when operating a rotary kiln. These regulations include:

- The Clean Air Act

- The Clean Water Act

- The Resource Conservation and Recovery Act

I am responsible for ensuring that the kiln meets all applicable environmental regulations.

7. What is the difference between a wet process and a dry process rotary kiln?

Wet Process Rotary Kiln

- In a wet process rotary kiln, the raw materials are mixed with water to form a slurry.

- The slurry is then fed into the kiln, where it is heated and dried.

Dry Process Rotary Kiln

- In a dry process rotary kiln, the raw materials are not mixed with water.

- Instead, the raw materials are fed into the kiln in a dry state.

8. What are the advantages and disadvantages of using a dry process rotary kiln?

Advantages of Dry Process Rotary Kiln

- Lower energy consumption

- Higher production rates

- Lower capital costs

Disadvantages of Dry Process Rotary Kiln

- Higher emissions

- More difficult to control

- Less efficient use of raw materials

9. What are the different types of refractory materials used in rotary kilns?

There are a number of different types of refractory materials used in rotary kilns. These materials include:

- Fireclay

- High-alumina

- Magnesia

- Zirconia

- Silicon carbide

The type of refractory material used in a particular kiln depends on the operating conditions of the kiln.

10. What are the factors that affect the life of a rotary kiln lining?

The life of a rotary kiln lining is affected by a number of factors, including:

- The type of refractory material used

- The operating temperature of the kiln

- The chemical composition of the raw materials being processed

- The presence of abrasive materials in the raw materials

- The maintenance practices used

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotary Kiln Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotary Kiln Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rotary Kiln Operators play a crucial role in the production process, ensuring the efficient and safe operation of rotary kilns. Their primary responsibilities include:

1. Kiln Operation

Monitors and controls kiln temperature, speed, and feed rate to optimize production

- Adjusts kiln parameters to maintain ideal burning conditions

- Identifies and resolves operational issues promptly

2. Equipment Maintenance

Performs routine inspections and preventive maintenance of the kiln and associated equipment

- Identifies and reports potential problems to maintenance personnel

- Participates in equipment repair and overhaul activities

3. Process Monitoring

Monitors process parameters, including feed quality, fuel consumption, and product quality

- Conducts regular sampling and testing to ensure product specifications are met

- Communicates process data to supervisors and team members

4. Safety and Environment

Adheres to established safety protocols and environmental regulations

- Operates the kiln in a safe and responsible manner

- Monitors emissions and takes corrective actions to minimize environmental impact

Interview Tips

Preparing for a Rotary Kiln Operator interview requires a thorough understanding of the role’s responsibilities and the ability to effectively convey your skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends

- Demonstrates your interest in the company and industry

- Shows you have taken the initiative to learn about potential workplace

2. Practice Answering Common Interview Questions

Prepare for questions related to kiln operation, equipment maintenance, process monitoring, and safety

- Example Outline:

- Tell me about a time you identified and resolved a critical kiln issue.

- Describe your experience in maintaining and repairing rotary kiln equipment.

- How do you ensure that the kiln is operated in compliance with safety and environmental regulations?

3. Highlight Your Relevant Skills and Experience

Emphasize your technical abilities, problem-solving skills, and previous experience in a similar role

- Quantify your accomplishments using specific examples

- Use action verbs and provide detailed descriptions of your contributions

4. Be Enthusiastic and Professional

Show your passion for the field and demonstrate your professionalism throughout the interview

- Maintain eye contact, ask thoughtful questions, and thank the interviewer for their time

- Dress appropriately and arrive on time for the interview

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Rotary Kiln Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Rotary Kiln Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.