Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rotary Lithographic Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

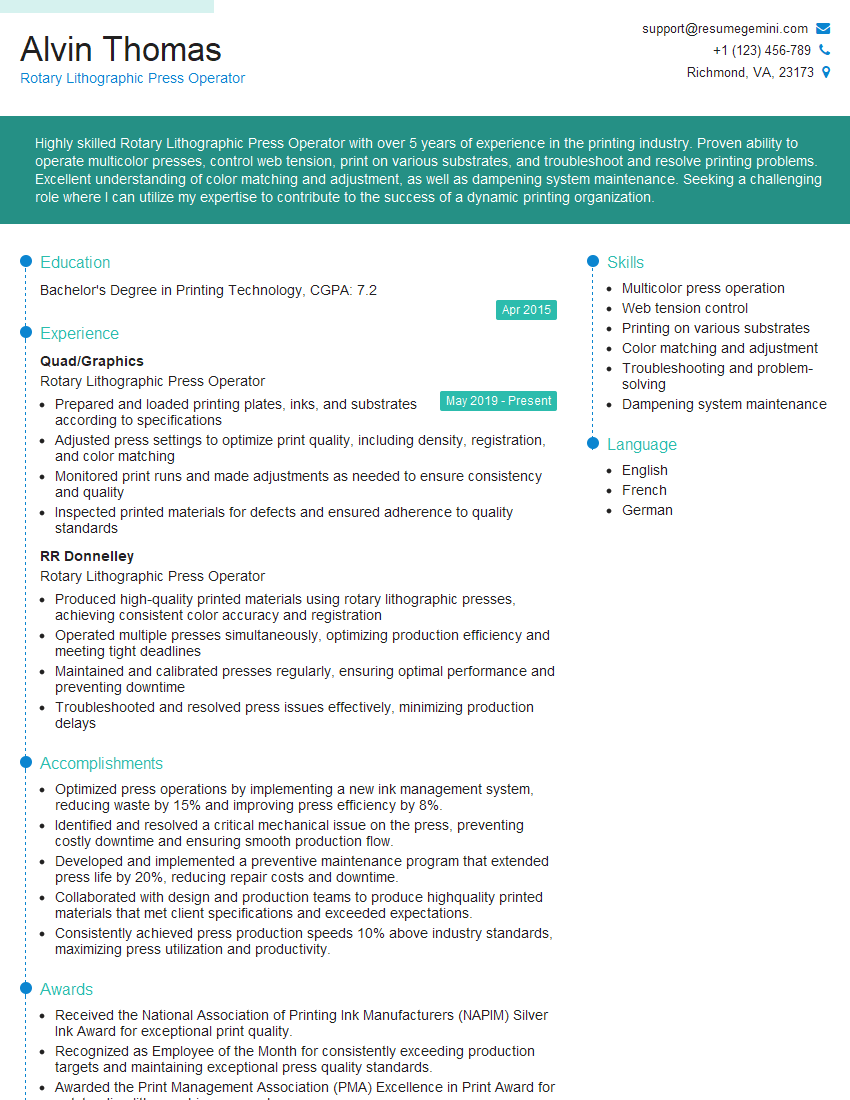

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotary Lithographic Press Operator

1. What are the key responsibilities of a Rotary Lithographic Press Operator?

As a Rotary Lithographic Press Operator, my responsibilities would include:

- Setting up and operating rotary lithographic printing presses

- Loading paper and other materials into the press

- Monitoring the printing process and making adjustments as needed

- Inspecting printed materials for quality and accuracy

- Maintaining and cleaning printing equipment

2. How do you ensure the quality of the printed materials?

: Pre-Printing Checks

- Inspecting the printing plates for any defects

- Checking the paper quality and ensuring it meets the specifications

- Calibrating the press to ensure accurate registration and color reproduction

Subheading: During Printing

- Monitoring the printing process continuously

- Making adjustments to the press as needed to maintain print quality

- Inspecting printed sheets regularly for any defects

Subheading: Post-Printing Checks

- Inspecting the finished printed materials thoroughly

- Ensuring that the color, registration, and overall quality meet the customer’s specifications

- Maintaining accurate records of printing parameters and quality control checks

3. What are the different types of printing presses used in rotary lithographic printing?

The different types of printing presses used in rotary lithographic printing include:

- Sheet-fed presses: These presses print on individual sheets of paper

- Web-fed presses: These presses print on a continuous roll of paper

- Offset presses: These presses use an intermediate blanket cylinder to transfer the image from the printing plate to the paper

- Digital presses: These presses use digital technology to create the image on the paper

4. What are the common challenges faced by Rotary Lithographic Press Operators?

Some of the common challenges faced by Rotary Lithographic Press Operators include:

- Maintaining consistent print quality

- Troubleshooting printing problems

- Meeting tight deadlines

- Working in a fast-paced environment

- Handling heavy materials

5. How do you stay up-to-date with the latest advancements in rotary lithographic printing technology?

I stay up-to-date with the latest advancements in rotary lithographic printing technology by:

- Attending industry conferences and workshops

- Reading trade publications and online articles

- Consulting with equipment manufacturers and suppliers

- Experimenting with new techniques and materials

6. What are the safety precautions that need to be taken when operating a rotary lithographic press?

The safety precautions that need to be taken when operating a rotary lithographic press include:

- Wearing appropriate safety gear, such as gloves, eye protection, and earplugs

- Keeping the work area clean and free of clutter

- Following proper lockout/tagout procedures when servicing the press

- Being aware of the location of emergency stop buttons

- Never reaching into the press while it is running

7. How do you calculate the paper consumption for a printing job?

To calculate the paper consumption for a printing job, I use the following formula:

Paper consumption = (Number of copies × Number of pages × Paper weight × Coverage factor) / 1000

- Number of copies: The number of copies to be printed

- Number of pages: The number of pages in each copy

- Paper weight: The weight of the paper in grams per square meter (gsm)

- Coverage factor: A factor that accounts for the amount of ink coverage on the paper

8. What are the different types of paper that can be used in rotary lithographic printing?

The different types of paper that can be used in rotary lithographic printing include:

- Offset paper: A high-quality paper that is specifically designed for offset printing

- Uncoated paper: A less expensive paper that is not coated with any special finishes

- Coated paper: A paper that has been coated with a special finish, such as a glossy or matte finish

- Recycled paper: A paper that has been made from recycled materials

9. What are the different types of inks that can be used in rotary lithographic printing?

The different types of inks that can be used in rotary lithographic printing include:

- Oil-based inks: Inks that are made from petroleum-based oils

- Water-based inks: Inks that are made from water-based emulsions

- UV-curable inks: Inks that are cured by exposure to ultraviolet light

- Specialty inks: Inks that are designed for specific applications, such as metallic inks or fluorescent inks

10. How do you troubleshoot printing problems?

When troubleshooting printing problems, I follow a systematic approach that includes:

- Identifying the problem

- Gathering information about the problem

- Analyzing the information

- Developing a solution

- Testing the solution

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotary Lithographic Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotary Lithographic Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rotary Lithographic Press Operator is an individual who is responsible for operating, maintaining, and troubleshooting rotary lithographic printing presses. These professionals play a crucial role in the printing industry, ensuring that high-quality printed products are produced efficiently and effectively. Their key responsibilities include:

1. Press Operation

Loading and aligning paper rolls or sheets on the press

- Setting up and adjusting printing plates on the press

- Monitoring the printing process, making necessary adjustments to ensure optimal print quality

2. Maintenance and Troubleshooting

Performing routine maintenance on the press, including cleaning, lubrication, and minor repairs

- Troubleshooting and resolving press malfunctions, minimizing downtime

- Ensuring that the press is operating safely and efficiently

3. Quality Control

Inspecting printed materials for defects and ensuring compliance with quality standards

- Making adjustments to the press or printing process to improve print quality

- Working closely with prepress and postpress departments to maintain color accuracy and consistency

4. Safety and Compliance

Following all safety regulations and guidelines when operating the press

- Maintaining a clean and organized work area

- Adhering to environmental regulations related to printing processes

Interview Tips

Preparing for a Rotary Lithographic Press Operator interview requires thorough research and practice. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and products or services. Research the specific job requirements and responsibilities to understand what the interviewer is looking for.

- Visit the company’s website and social media pages

- Read industry news and articles to stay updated on the latest trends

2. Practice Common Interview Questions

Prepare answers to common interview questions, such as: “Tell me about yourself,” “Why are you interested in this position?,” and “What are your strengths and weaknesses?” Practice these questions in front of a mirror or with a friend or family member.

- Tailor your answers to the specific job requirements

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible using metrics or data. Use action verbs and specific examples to demonstrate your abilities.

- Provide examples of successful press operations, maintenance, and troubleshooting experiences

- Highlight your knowledge of printing processes, substrates, and inks

4. Be Enthusiastic and Professional

Show your enthusiasm for the printing industry and your desire to join the company. Dress professionally, arrive on time, and maintain a positive and respectful demeanor throughout the interview. Remember to ask thoughtful questions and listen attentively to the interviewer’s responses.

- Prepare questions about the company’s printing capabilities, production processes, and career advancement opportunities

- Thank the interviewer for their time and consideration and follow up with a thank-you note

Next Step:

Now that you’re armed with the knowledge of Rotary Lithographic Press Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rotary Lithographic Press Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini