Are you gearing up for a career in Rotary Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rotary Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

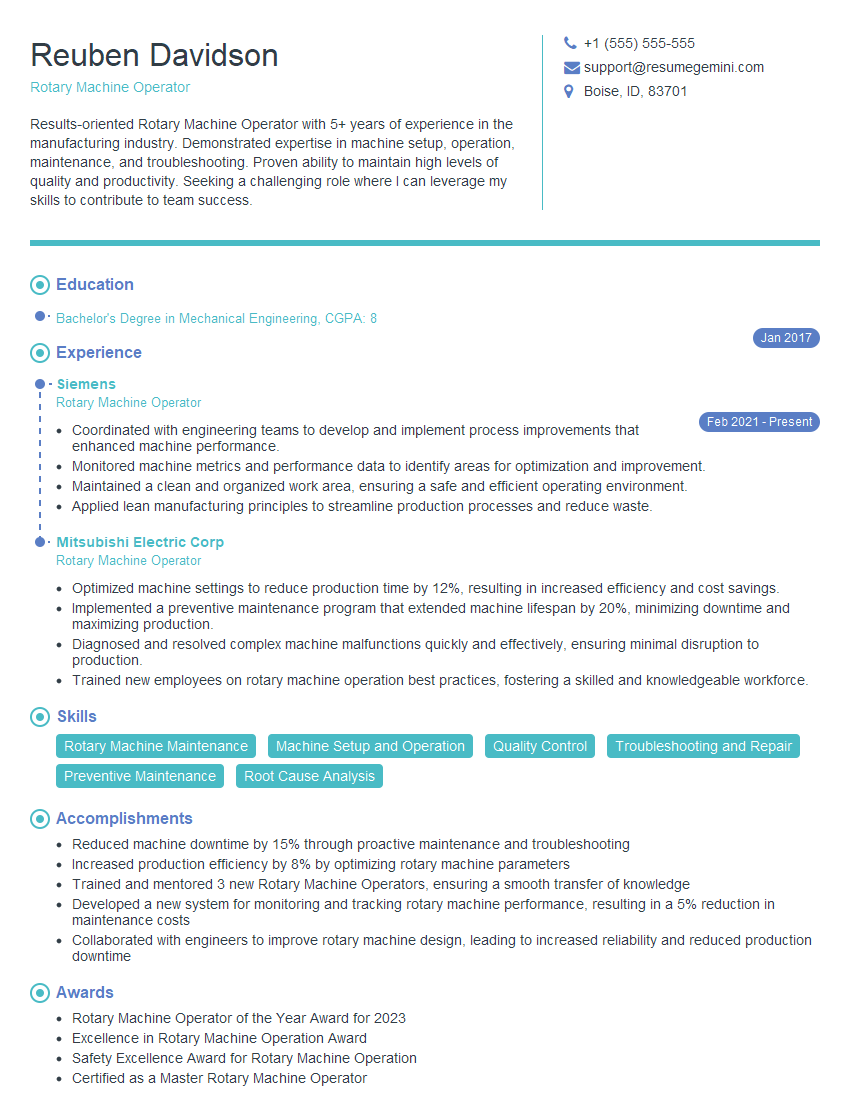

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotary Machine Operator

1. Explain the process of setting up a rotary machine?

In setting up a rotary machine, I follow a systematic procedure:

- I first secure the machine to the foundation or base.

- Next, I install the necessary tools and accessories, such as rotary heads, spindles, and tool holders.

- I then align the workpiece correctly and secure it in place.

- After that, I set the machine parameters, including speed, feed, and depth of cut.

- Finally, I run a test cycle to ensure that the machine is operating correctly.

2. What are the different types of rotary machines and their applications?

CNC Rotary Machines

- Precisely control complex cutting paths.

- Used in industries such as aerospace, automotive, and mold-making.

Transfer Rotary Machines

- Mass-produce parts by transferring them between multiple stations.

- Common in industries like automotive and electronics.

Indexing Rotary Machines

- Divide a circular workpiece into equal segments for precise machining.

- Used in industries like watchmaking and precision parts manufacturing.

3. How do you troubleshoot common rotary machine problems?

Troubleshooting rotary machine problems requires a systematic approach:

- First, I identify the symptoms of the problem.

- Next, I consult technical manuals and consult with colleagues to determine possible causes.

- I then conduct tests to isolate the problem, such as checking for loose connections, worn parts, or incorrect settings.

- After identifying the root cause, I can implement solutions, such as replacing worn parts, adjusting settings, or performing maintenance.

- Finally, I verify that the problem has been resolved by running a test cycle.

4. What are the safety precautions to consider when operating a rotary machine?

- Ensure proper guarding and safety devices are in place.

- Wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Keep the work area clean and free of debris.

- Never operate the machine when under the influence of drugs or alcohol.

- Follow all established safety protocols and procedures.

5. How do you maintain and calibrate a rotary machine?

Maintaining a rotary machine involves:

- Regular cleaning and lubrication of all components.

- Replacing worn or damaged parts promptly.

- Conducting periodic inspections to identify potential issues.

- Calibrating the machine to ensure accuracy and precision.

- Following the manufacturer’s recommended maintenance schedule.

6. What is the difference between a rotary head and a fixed head?

Rotary Head

- Rotates on its axis, allowing for complex part geometries.

- Used in CNC rotary machines.

Fixed Head

- Stationary, with the workpiece rotating around it.

- Used in indexing and transfer rotary machines.

7. Explain the principles of rotary table indexing.

Rotary table indexing involves:

- Dividing a workpiece into equal segments for precise machining.

- Rotating the table in increments to expose different segments to the cutting tool.

- Using an index plate or encoder to control the angular movement.

8. What factors affect the cutting speeds and feeds used in rotary machines?

- Material properties (hardness, strength, ductility)

- Tool type and geometry

- Machine power and rigidity

- Desired surface finish and part accuracy

- Coolant and lubrication used

9. Describe the role of CAM software in rotary machine programming.

CAM software plays a crucial role in rotary machine programming:

- Creates toolpaths and G-code for complex part geometries.

- Simulates machine operations to verify accuracy and avoid collisions.

- Optimizes cutting parameters and machine movements for efficiency.

10. How do you stay up-to-date on the latest rotary machine technologies?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Consult with machine manufacturers and suppliers.

- Engage in online forums and discussions.

- Receive training and certifications from reputable organizations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotary Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotary Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rotary Machine Operators are responsible for operating and maintaining rotary machines, which are used to manufacture a variety of products. They work in a variety of industries, including automotive, aerospace, and manufacturing.

1. Machine Operation

Rotary Machine Operators are responsible for setting up, operating, and maintaining rotary machines. They must be able to read and understand blueprints and other technical documentation. They must also be able to operate the machine safely and efficiently.

- Set up and operate rotary machines according to blueprints and work orders.

- Monitor machine operation and make adjustments as needed.

- Troubleshoot and repair machine malfunctions.

- Maintain a clean and safe work area.

2. Quality Control

Rotary Machine Operators are responsible for ensuring that the products produced by the machine meet quality standards. They must be able to inspect products for defects and make adjustments to the machine as needed.

- Inspect products for defects.

- Make adjustments to the machine to ensure that products meet quality standards.

- Maintain records of product quality.

3. Safety

Rotary Machine Operators must be aware of the safety hazards associated with their work. They must be able to follow safety procedures and wear appropriate protective gear.

- Follow safety procedures.

- Wear appropriate protective gear.

- Report any safety hazards to their supervisor.

4. Maintenance

Rotary Machine Operators are responsible for maintaining the rotary machines they operate. They must be able to perform routine maintenance tasks, such as cleaning, lubrication, and inspection.

- Perform routine maintenance tasks.

- Repair minor machine malfunctions.

- Order replacement parts as needed.

Interview Tips

Preparing for an interview for a Rotary Machine Operator position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website.

- Read the job description carefully.

- Talk to your network to see if anyone knows about the company or position.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioural interview questions.

- Be specific and provide examples when answering questions.

- Tailor your answers to the specific job you are applying for.

3. Be Prepared to Talk About Your Skills and Experience

The interviewer will want to know about your skills and experience as a Rotary Machine Operator. Be prepared to discuss your experience in detail, including the types of machines you have operated, the products you have produced, and the quality standards you have met.

- Quantify your accomplishments whenever possible.

- Use action verbs to describe your skills and experience.

- Be prepared to talk about your safety record.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the company and the position. This shows that you are interested in the job and that you are taking the interview seriously.

- Ask about the company’s culture.

- Ask about the company’s growth plans.

- Ask about the specific responsibilities of the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rotary Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.