Are you gearing up for an interview for a Rotary Shear Cutter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rotary Shear Cutter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

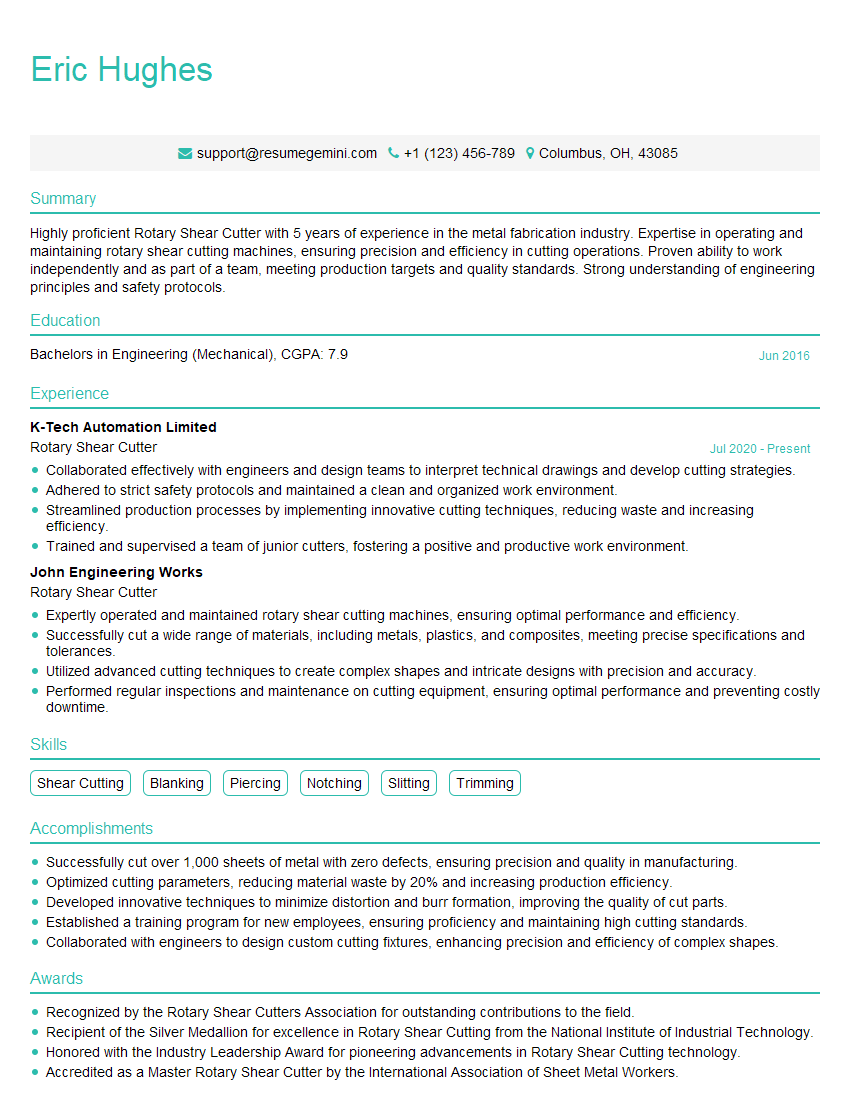

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotary Shear Cutter

1. Explain the working principle of a rotary shear cutter.

A rotary shear cutter operates on the principle of shearing, where a rotating blade moves tangentially against a stationary blade, resulting in a clean and precise cut.

- The rotating blade is driven by a motor, typically powered by electricity.

- The stationary blade is fixed in place and designed to withstand the cutting forces.

- The material to be cut is fed between the blades, and the rotating blade exerts a shearing action, cleanly separating the material.

2. What are the different types of rotary shear cutters available?

Mechanical Rotary Shear Cutter

- Uses a mechanical transmission system to drive the rotating blade.

- Requires regular maintenance and lubrication.

Hydraulic Rotary Shear Cutter

- Employs hydraulic pressure to drive the rotating blade.

- Provides higher power and control.

3. What factors should be considered when selecting a rotary shear cutter?

Several factors influence the selection of a rotary shear cutter:

- Material type and thickness to be cut.

- Required cutting speed and accuracy.

- Size and shape of the workpiece.

- Available space and power supply.

- Budgetary constraints.

4. How do you ensure the accuracy and precision of a rotary shear cut?

To achieve accurate and precise cuts:

- The blades must be sharp and properly aligned.

- The material must be securely held in place during cutting.

- The cutting speed and pressure should be optimized for the specific material.

- Regular calibration and maintenance are necessary to ensure ongoing accuracy.

5. What are the safety precautions to observe when operating a rotary shear cutter?

Operating a rotary shear cutter involves several safety precautions:

- Always wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Keep hands clear of the operating blades.

- Ensure the machine is properly grounded to prevent electrical hazards.

- Never attempt to operate a faulty or damaged cutter.

- Follow the manufacturer’s operating instructions carefully.

6. How do you troubleshoot common problems encountered with rotary shear cutters?

Common problems with rotary shear cutters and their troubleshooting steps include:

- Dull blades: Replace or sharpen the blades.

- Misaligned blades: Adjust the blade alignment according to the manufacturer’s specifications.

- Inadequate cutting power: Check the power supply and motor performance.

- Jammed material: Clear the jammed material and ensure the feeding mechanism is functioning properly.

7. What are the advantages of using a rotary shear cutter over other cutting methods?

Rotary shear cutters offer several advantages:

- Clean and precise cuts with minimal burrs.

- High cutting speed and efficiency.

- Ability to cut a wide range of materials.

- Compact and versatile, suitable for various applications.

8. How do you maintain a rotary shear cutter for optimal performance?

Regular maintenance is crucial for optimal performance:

- Lubricate moving parts as per the manufacturer’s instructions.

- Inspect blades for sharpness and alignment, and replace or adjust as needed.

- Clean the machine regularly to remove any debris or metal shavings.

- Follow the manufacturer’s recommended maintenance schedule.

- Store the cutter in a dry and protected environment when not in use.

9. Describe the different materials that can be cut using a rotary shear cutter.

Rotary shear cutters can cut various materials, including:

- Metals (e.g., aluminum, stainless steel, copper)

- Plastics (e.g., ABS, PVC, polycarbonate)

- Rubber and gaskets.

- Composite materials (e.g., fiberglass, carbon fiber)

10. How do you adjust the cutting angle and depth of a rotary shear cutter?

Cutting angle and depth adjustment vary depending on the machine model:

- Cutting angle: Usually adjustable by changing the inclination of the stationary blade.

- Cutting depth: Typically adjusted by setting the gap between the blades or using a depth stop.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotary Shear Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotary Shear Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A rotary shear cutter operates a rotary shear cutter, a machine that cuts and trims sheet metal, plastics, and other materials. The key job responsibilities of a rotary shear cutter include:

1. Loading and positioning materials

The operator loads and positions the material to be cut onto the rotary shear cutter’s table.

2. Setting up and operating the machine

The operator sets up the machine according to the required specifications, including the blade gap, cutting speed, and feed rate. They then start the machine and ensure that it is running smoothly.

3. Monitoring the cutting process

The operator monitors the cutting process to ensure that the material is being cut accurately and to the desired specifications. They also make adjustments to the machine as needed.

4. Inspecting the finished product

The operator inspects the finished product to ensure that it meets the required quality standards. They also remove any scrap material from the machine.

5. Maintaining the machine

The operator performs routine maintenance on the rotary shear cutter, including cleaning, lubrication, and blade sharpening.

6. Troubleshooting and repairing minor malfunctions

The operator troubleshoots and repairs minor malfunctions that occur with the machine. They also report any major malfunctions to their supervisor.

Interview Tips

To prepare for an interview, candidates should do the following:

1. Research the company and the position

Candidates should research the company and the position they are applying for. This will help them understand the company’s culture, values, and the specific requirements of the position.

2. Practice answering common interview questions

Candidates should practice answering common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. They should also prepare questions to ask the interviewer about the position and the company.

3. Dress professionally

Candidates should dress professionally for the interview. This shows that they are taking the interview seriously and that they are interested in making a good impression.

4. Be on time

Candidates should be on time for the interview. This shows that they are organized and that they respect the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rotary Shear Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!