Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Roto Gravure Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

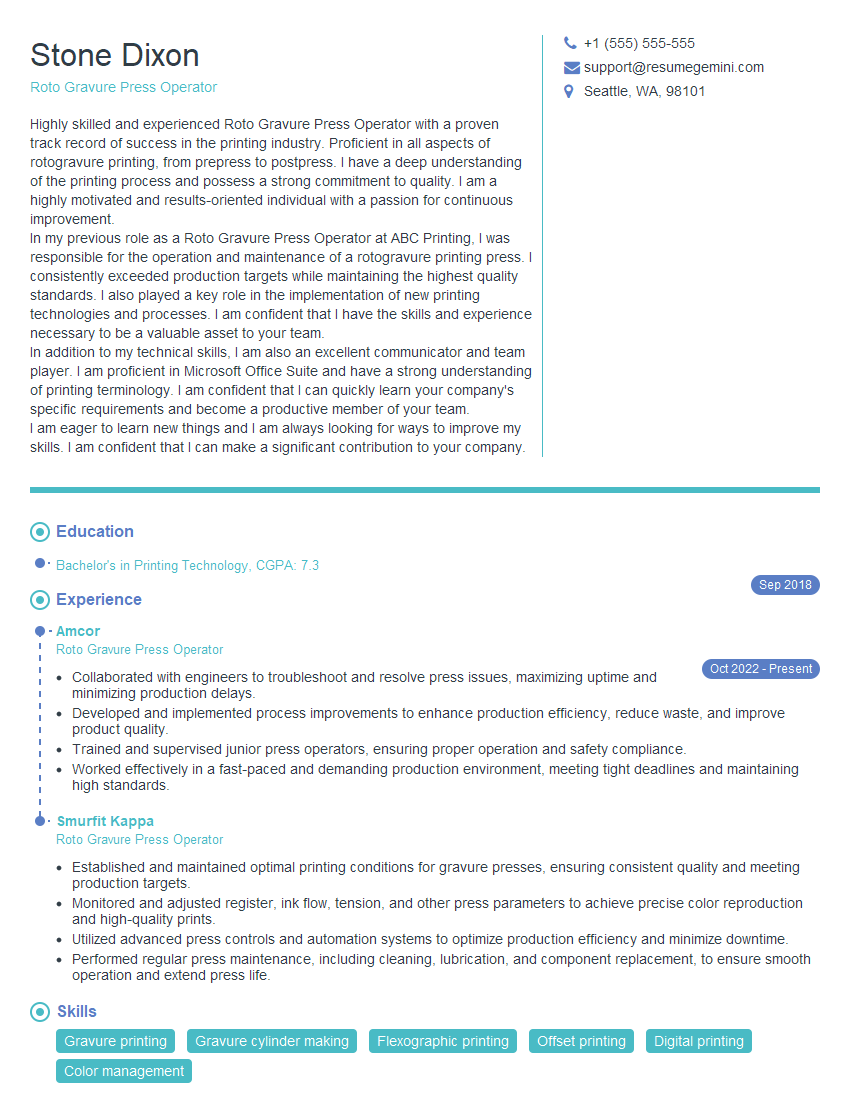

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roto Gravure Press Operator

1. Describe the process of setting up a rotogravure printing press

To set up a rotogravure printing press, I follow a systematic procedure that ensures optimal performance and print quality:

- Inspect the press: Before starting, I thoroughly inspect the press for any issues or maintenance needs, ensuring it is in good working condition.

- Mount the cylinders: I carefully mount the gravure cylinders onto the press, ensuring proper alignment and tension.

- Set the ink fountains: I adjust the ink fountains to the correct level and viscosity to deliver consistent ink flow during printing.

- Prepare the substrate: I prepare the substrate (paper or film) by ensuring it is properly loaded and tensioned, ensuring wrinkle-free printing.

- Calibrate the registration: I meticulously calibrate the registration system to align the colors precisely, preventing misprints and ensuring high-quality output.

2. How do you troubleshoot and resolve common printing defects in rotogravure printing?

- Dot gain: I analyze the print to detect excessive dot gain, which can occur due to improper ink viscosity or excessive pressure. To rectify it, I adjust the ink or press settings accordingly.

- Mottling: If visible mottling appears on the print, it indicates uneven ink transfer. I check the cylinders for damage or contamination and clean them thoroughly to resolve the issue.

- Ghosting: I inspect the press to identify the source of ghosting, which can be caused by misalignment or worn cylinders. I realign the press components and replace worn parts as needed.

- Haze: When a hazy appearance is present in the print, it suggests insufficient ink transfer. I check the ink viscosity, ink flow, and cylinder pressure to optimize ink transfer and eliminate haze.

3. How do you maintain the rotogravure press to ensure optimal performance and longevity?

To maintain optimal press performance and extend its lifespan, I follow a comprehensive maintenance routine:

- Regular cleaning: I diligently clean the press components, including cylinders, ink fountains, and rollers, to prevent ink buildup and ensure smooth operation.

- Cylinder inspection: I regularly inspect the gravure cylinders for wear, damage, or corrosion and address any issues promptly to maintain print quality.

- Lubrication: I lubricate moving parts according to the manufacturer’s recommendations to reduce friction and wear, ensuring smooth press operation.

- Press adjustments: I perform necessary press adjustments, such as tensioning belts and aligning components, to maintain accuracy and prevent breakdowns.

4. What safety precautions should be taken when operating a rotogravure printing press?

I prioritize safety by adhering to the following precautions during press operation:

- Proper attire: I wear appropriate clothing, including gloves and safety glasses, to protect myself from ink, solvents, and moving machinery.

- Guarding: I ensure that all press guards and safety devices are in place and functioning correctly to prevent accidents.

- Lockout/tagout: I follow lockout/tagout procedures before performing any maintenance or cleaning tasks to prevent accidental startups.

- Chemical handling: I handle solvents and inks safely, wearing appropriate protective gear and following proper disposal procedures.

5. What are the different types of inks used in rotogravure printing, and how do their properties affect the printing process?

In rotogravure printing, various types of inks are used, each with unique properties that influence the printing process:

- Solvent-based inks: These inks contain volatile organic compounds (VOCs) and offer excellent adhesion and durability. They require special handling and disposal due to their environmental impact.

- Water-based inks: These inks use water as their primary solvent, making them more environmentally friendly. They provide good print quality but may have limitations in certain applications.

- UV-curable inks: These inks cure instantly upon exposure to ultraviolet light, resulting in fast drying times and high-gloss finishes. They are often used for specialized printing applications.

6. How do you calculate the ink coverage of a rotogravure printing job?

To calculate the ink coverage of a rotogravure printing job, I use the following formula:

- Ink coverage (%) = (Ink weight (kg) / Paper weight (kg)) x 100

This formula provides an accurate estimate of the amount of ink required to cover the printed area, helping me plan ink usage and optimize printing costs.

7. What are the advantages of using rotogravure printing over other printing methods?

- High-quality output: Rotogravure printing produces exceptional print quality with fine details, vibrant colors, and smooth transitions.

- Long print runs: Rotogravure presses are designed for high-volume printing and can produce millions of impressions consistently.

- Cost-effective for large quantities: For large print runs, rotogravure printing offers a cost-effective solution compared to other printing methods.

- Suitable for various substrates: Rotogravure printing can handle a wide range of substrates, including paper, film, and foil.

8. What are the challenges of working as a rotogravure press operator, and how do you overcome them?

Working as a rotogravure press operator presents certain challenges, but I approach them with a proactive and solution-oriented mindset:

- Maintaining accuracy: Achieving precise registration and color consistency requires meticulous attention to detail. I use measuring tools and rely on my experience to ensure accurate printing.

- Troubleshooting press issues: Unexpected press issues can arise, but I remain calm and systematically troubleshoot the problem. By understanding the press mechanics and utilizing diagnostic tools, I resolve issues efficiently.

- Working in a fast-paced environment: Rotogravure presses operate at high speeds, demanding quick decision-making and multitasking. I maintain focus and prioritize tasks to meet deadlines without compromising quality.

9. Describe your experience in managing multiple printing jobs simultaneously.

In my previous role, I often managed multiple printing jobs simultaneously, ensuring efficient production and meeting client deadlines:

- Job prioritization: I assessed the importance and lead times of each job, prioritizing urgent orders while maintaining quality standards for all.

- Scheduling and coordination: I coordinated with the press team to schedule press time effectively, ensuring smooth transitions between jobs.

- Communication: I maintained open communication with clients, providing regular updates on job progress and addressing any concerns promptly.

10. How do you stay up-to-date with advancements in rotogravure printing technology?

- Industry events: I attend industry conferences and exhibitions to learn about the latest technologies and best practices.

- Technical publications: I subscribe to industry magazines and online forums to stay informed about new developments.

- Manufacturer training: I participate in training programs offered by press manufacturers to enhance my knowledge and skills on advanced equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roto Gravure Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roto Gravure Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rotogravure Press Operator is an essential member of the printing industry responsible for operating rotogravure presses to produce high-quality printed materials. Their primary responsibilities include:1. Press Operation and Maintenance

Operate and maintain rotogravure printing presses, ensuring smooth and efficient operation.

- Adjust and calibrate equipment for optimal print quality and productivity.

- Monitor press performance, identify and resolve any issues promptly.

2. Color Management

Control and optimize ink and color settings to achieve accurate and consistent color reproduction.

- Analyze color proofs, adjust color settings, and create color profiles.

- Work closely with prepress and design teams to ensure accurate color matching.

3. Quality Control

Inspect printed materials to ensure they meet quality standards and customer specifications.

- Identify and correct defects, such as registration errors, ink variations, and color deviations.

- Maintain detailed records of quality checks and associated corrections.

4. Production Management

Plan and schedule production runs, ensuring timely delivery of printed materials.

- Estimate and manage material usage, including paper, ink, and cleaning supplies.

- Coordinate with other departments, such as prepress and bindery, to optimize workflow.

Interview Tips

To ace the interview for a Rotogravure Press Operator position, consider these tips:1. Preparation

Thoroughly review the job description and identify the key responsibilities.

- Highlight your experience and skills that directly relate to the job requirements.

- Prepare examples that demonstrate your technical knowledge and problem-solving abilities.

2. Communication

Be clear and concise when answering interview questions.

- Use specific examples to illustrate your accomplishments and skills.

- Listen carefully to the interviewer’s questions and provide thoughtful responses.

3. Enthusiasm and Passion

Convey your passion for printing and your commitment to producing high-quality work.

- Explain how you stay up-to-date with industry best practices and technological advancements.

- Share your experience in handling challenging printing situations and finding effective solutions.

4. Flexibility and Adaptability

Demonstrate your ability to work in a fast-paced, demanding environment.

- Discuss your willingness to work overtime or on weekends to meet production deadlines.

- Emphasize your ability to adjust to changing work priorities and unforeseen circumstances.

Next Step:

Now that you’re armed with the knowledge of Roto Gravure Press Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Roto Gravure Press Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini