Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rotor Casting Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

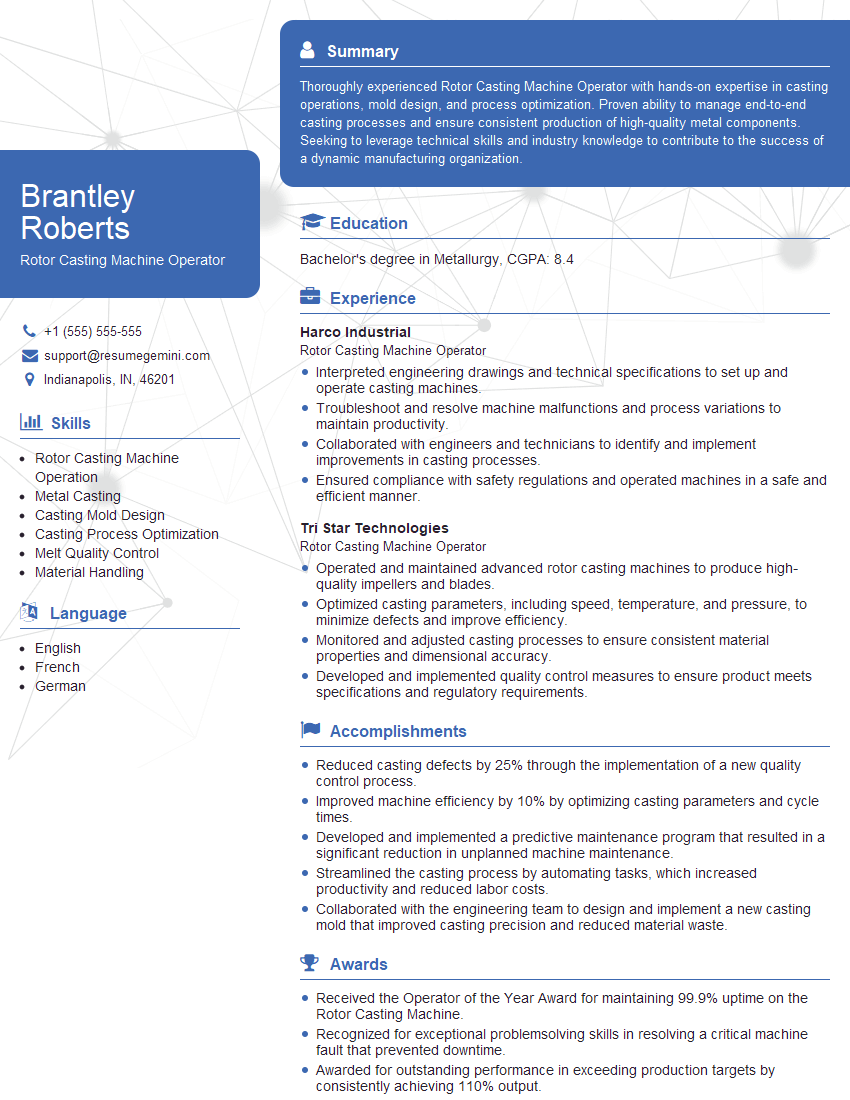

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rotor Casting Machine Operator

1. Explain the main components of a Rotor Casting Machine and their functions.

- Melting and Holding Furnace: Melts the metal and holds it at the desired casting temperature.

- Rotor Casting Mold: A spinning cylindrical mold into which the molten metal is poured to form the rotor.

- Rotor Casting Head: Houses the runner and gating system that controls the flow of molten metal into the mold.

- Cooling System: Cools the cast rotor to its solidification temperature.

- Ejection System: Ejects the solidified rotor from the mold.

2. Describe the different types of rotor casting processes and their advantages and disadvantages.

Centrifugal Casting

- Advantages: Produces high-quality castings with good surface finish and dimensional accuracy.

- Disadvantages: Requires specialized equipment and high production volumes for cost-effectiveness.

Vacuum Centrifugal Casting

- Advantages: Eliminates porosity and inclusions, resulting in superior castings.

- Disadvantages: Complex and expensive process, suitable for small and precision castings.

Pressure Die Casting

- Advantages: High production rates, low-cost tooling, and good surface finish.

- Disadvantages: Limited to smaller castings, potential for porosity in thick sections.

3. How do you control the quality of rotor castings?

- Inspect raw materials and components before casting.

- Monitor process parameters (e.g., temperature, speed, pressure) during casting.

- Perform non-destructive testing (e.g., X-ray, ultrasound) on finished castings.

- Maintain and calibrate equipment regularly.

- Establish and implement quality control procedures.

4. What are the common defects in rotor castings and how can they be prevented?

- Porosity: Caused by air entrapment or shrinkage during solidification. Can be prevented by vacuum degassing, proper gating design, and slow cooling.

- Inclusions: Foreign particles trapped in the casting. Can be prevented by proper melting practices, filtration, and clean molding materials.

- Cracks: Caused by thermal stresses or excessive cooling rates. Can be prevented by proper heat treatment and gradual cooling.

- Misruns: Incomplete filling of the mold. Can be prevented by proper mold design, adequate pouring temperature, and clean metal.

5. Explain the importance of mold design in rotor casting.

- Determines the shape and dimensions of the casting.

- Controls the flow of molten metal into the mold.

- Affects the cooling rate of the casting, which influences its properties.

- Must be designed to minimize defects and ensure casting quality.

6. How do you calculate the pouring temperature for a rotor casting?

- Consider the melting point of the metal.

- Account for heat losses during pouring and solidification.

- Ensure that the temperature is high enough for proper flow but not too high to cause overheating or burning.

- Use empirical formulas or software to determine the optimal pouring temperature.

7. What are the safety precautions to be observed when operating a Rotor Casting Machine?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Follow proper procedures for handling molten metal.

- Maintain good housekeeping to prevent tripping hazards.

- Be aware of potential electrical hazards and ensure proper grounding.

- Follow emergency procedures in case of accidents.

8. How do you troubleshoot common problems that may arise during rotor casting?

- Porosity: Inspect for proper degassing, mold design, and cooling rates.

- Inclusions: Check melting practices, filtration, and molding materials.

- Cracks: Adjust cooling rates, perform heat treatment, or investigate material properties.

- Misruns: Verify mold design, pouring temperature, and metal flow.

9. Describe the role of metallurgy in rotor casting.

- Selection of suitable alloys for specific applications.

- Understanding the effects of heat treatment on casting properties.

- Developing processes to optimize casting microstructure and performance.

- Analysis of casting defects and failure mechanisms.

10. What are the latest advancements in rotor casting technology?

- Advanced mold design techniques: Use of computer simulation to optimize mold geometry.

- Vacuum-assisted casting: Improved casting quality by removing air entrapment.

- Semi-solid casting: Reduces defects and improves mechanical properties.

- Automated casting systems: Increased efficiency and consistency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rotor Casting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rotor Casting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rotor Casting Machine Operators are responsible for the safe and efficient operation of rotor casting machines, which produce rotors for electric motors and generators. Their key responsibilities include:

1. Preparing the machine for operation

This includes setting up the machine, installing the mold, and loading the materials.

- Ensuring that the machine is properly calibrated and adjusted.

- Inspecting the mold for any defects.

- Loading the materials, such as molten metal and binding agents, into the machine.

2. Monitoring the casting process

Once the machine is running, the operator must monitor the casting process to ensure that it is proceeding smoothly.

- Observing the molten metal as it flows into the mold.

- Checking the temperature of the metal.

- Adjusting the machine settings as needed.

3. Removing the finished castings from the machine

Once the casting process is complete, the operator must remove the finished castings from the machine.

- Allowing the castings to cool.

- Removing the castings from the mold.

- Inspecting the castings for any defects.

4. Cleaning and maintaining the machine

The operator is also responsible for cleaning and maintaining the machine.

- Cleaning the machine after each use.

- Lubricating the machine.

- Inspecting the machine for any damage.

Interview Tips

To ace an interview for a Rotor Casting Machine Operator position, you should be prepared to discuss your experience and qualifications, as well as your knowledge of the casting process. Here are a few tips to help you prepare for your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website.

- Read the job description carefully.

- Look for news articles or social media posts about the company.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and clearly.

- Use the STAR method to answer behavioral questions.

- Focus on your skills and experience that are relevant to the job.

- Be concise and to the point.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience operating rotor casting machines. Be prepared to discuss your responsibilities, your accomplishments, and any challenges you have faced.

- Quantify your accomplishments whenever possible.

- Highlight your experience with different types of rotor casting machines.

- Describe any safety procedures you have implemented or followed.

4. Be prepared to ask questions

At the end of the interview, the interviewer will likely give you an opportunity to ask questions. This is your chance to learn more about the company and the position. It is also a good way to show the interviewer that you are interested in the job.

- Ask about the company’s culture.

- Ask about the company’s plans for the future.

- Ask about the specific responsibilities of the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rotor Casting Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.