Feeling lost in a sea of interview questions? Landed that dream interview for Rough and Trueing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Rough and Trueing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

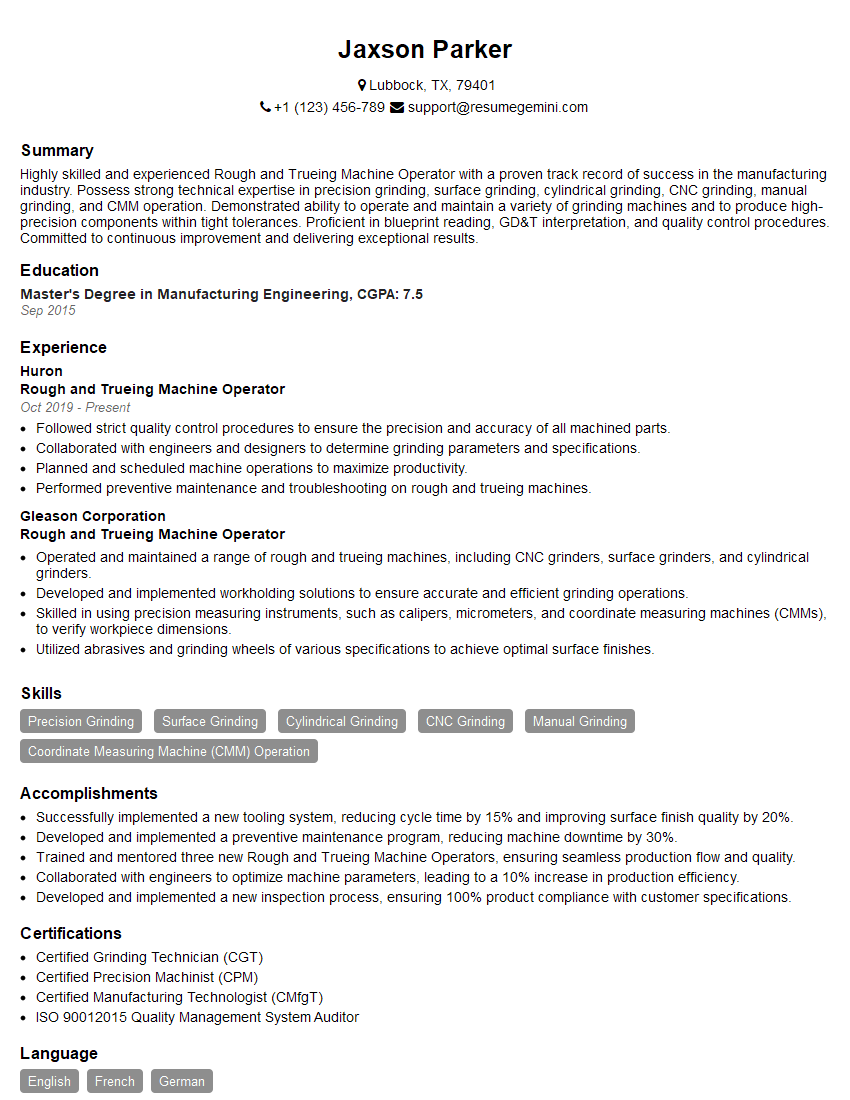

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rough and Trueing Machine Operator

1. What is the purpose of a rough and trueing machine?

The purpose of a rough and trueing machine is to grind the surface of a workpiece to achieve a desired shape, size, and surface finish. It is used to prepare workpieces for further processing, such as machining, grinding, or polishing.

2. What are the different types of rough and trueing machines?

Surface grinders

- Flat surface grinders

- Rotary surface grinders

Cylindrical grinders

- Centerless grinders

- Internal grinders

- External grinders

Other types

- Blanchard grinders

- Tool and cutter grinders

3. What are the key factors to consider when selecting a rough and trueing machine?

Key factors to consider when selecting a rough and trueing machine include:

- Workpiece size and shape

- Desired surface finish

- Production volume

- Budget

4. What are the different types of grinding wheels used in rough and trueing machines?

Different types of grinding wheels used in rough and trueing machines include:

- Diamond wheels

- CBN wheels

- Aluminum oxide wheels

- Silicon carbide wheels

5. What are the safety precautions that must be taken when operating a rough and trueing machine?

Safety precautions that must be taken when operating a rough and trueing machine include:

- Wearing proper safety gear (safety glasses, gloves, earplugs)

- Inspecting the machine before each use

- Ensuring that the workpiece is properly secured

- Using the correct grinding wheel for the job

- Never operating the machine while under the influence of drugs or alcohol

6. What are the common problems that can occur when operating a rough and trueing machine?

Common problems that can occur when operating a rough and trueing machine include:

- Chatter

- Burning

- Glazing

- Loading

7. How do you troubleshoot and correct common problems that occur when operating a rough and trueing machine?

Troubleshooting and correcting common problems that occur when operating a rough and trueing machine involve:

- Identifying the problem

- Determining the cause of the problem

- Taking corrective action

- Verifying that the problem has been corrected

8. What is the difference between roughing and trueing?

Roughing is the process of removing excess material from a workpiece to achieve the desired shape and size. Trueing is the process of finishing the surface of a workpiece to achieve the desired surface finish.

9. What are the different types of coolants used in rough and trueing machines?

Different types of coolants used in rough and trueing machines include:

- Water-based coolants

- Oil-based coolants

- Synthetic coolants

10. What are the benefits of using a coolant in a rough and trueing machine?

Benefits of using a coolant in a rough and trueing machine include:

- Improved surface finish

- Reduced chatter

- Extended wheel life

- Reduced risk of thermal damage to the workpiece

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rough and Trueing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rough and Trueing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rough and Trueing Machine Operators are responsible for operating and maintaining roughing and trueing machines. They use these machines to grind and shape metal surfaces, ensuring that they meet the required specifications. Their key job responsibilities include:

1. Operating Rough and Trueing Machines

Operators are responsible for setting up, operating, and monitoring roughing and trueing machines. They must ensure that the machines are properly calibrated and adjusted to meet the desired specifications.

- Setting up and adjusting machines according to specifications

- Loading and unloading workpieces

- Monitoring the grinding process and making adjustments as needed

2. Grinding and Shaping Metal Surfaces

Operators use roughing and trueing machines to grind and shape metal surfaces. They must have a good understanding of the different types of grinding wheels and how to use them to achieve the desired results.

- Selecting the appropriate grinding wheels for the job

- Grinding and shaping metal surfaces to meet specifications

- Finishing and polishing surfaces as needed

3. Inspecting and Measuring Workpieces

Operators must inspect and measure workpieces to ensure that they meet the required specifications. They use precision measuring tools and gauges to check the dimensions and tolerances of the workpieces.

- Inspecting workpieces for defects

- Measuring workpieces to ensure that they meet specifications

- Making adjustments to the grinding process as needed

4. Maintaining Rough and Trueing Machines

Operators are responsible for maintaining roughing and trueing machines. They must perform regular maintenance tasks, such as cleaning, lubrication, and repairs. They must also troubleshoot and resolve any problems that occur with the machines.

- Cleaning and lubricating machines

- Performing minor repairs and adjustments

- Troubleshooting and resolving problems

Interview Tips

To prepare for an interview for a Rough and Trueing Machine Operator position, it is important to have a strong understanding of the job responsibilities and the skills and experience required to perform the job effectively. Here are some tips to help you ace the interview:

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on its website, social media pages, and Glassdoor.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice answering these questions in a clear and concise manner. You can also prepare for specific questions related to the job responsibilities, such as “What experience do you have operating roughing and trueing machines?”

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the job. This includes your technical skills, such as your experience operating roughing and trueing machines, as well as your soft skills, such as your attention to detail and your ability to work independently. You can also mention any certifications or training that you have that are relevant to the job.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the job and that you are taking the interview seriously. You can also ask about the company’s culture and values, as well as the opportunities for advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rough and Trueing Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.