Feeling lost in a sea of interview questions? Landed that dream interview for Roughing Mill Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Roughing Mill Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

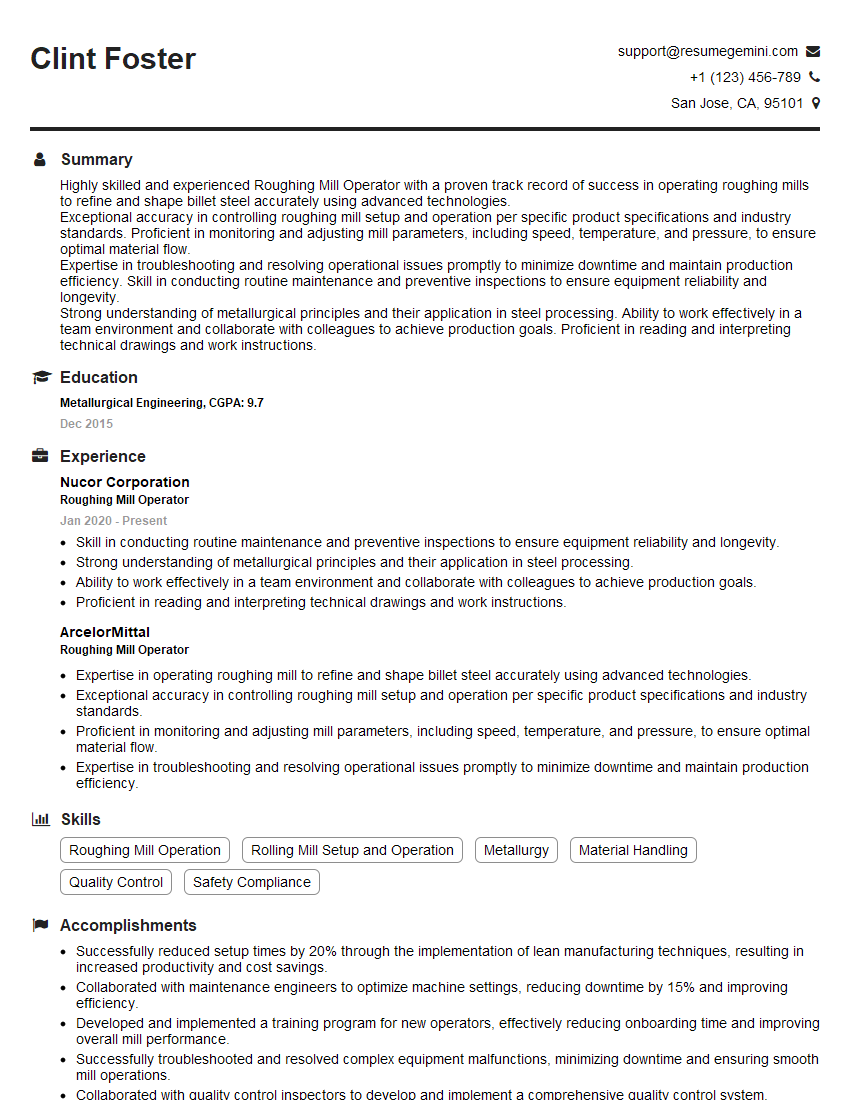

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roughing Mill Operator

1. What is the purpose of a roughing mill?

The purpose of a roughing mill is to reduce the cross-sectional area of a workpiece by rolling it between two rolls, thereby forming it into a desired shape.

2. Describe the components of a roughing mill.

Housing

- Houses the rolls

- Provides strength and rigidity

Rolls

- Cylindrical or shaped

- Rotate to reduce the cross-sectional area of the workpiece

Bearings

- Support and guide the rolls

- Reduce friction

Mill Stands

- Hold the housing

- Adjust the rolls

3. What types of materials can be processed in a roughing mill?

A roughing mill can process various materials, including:

- Steel

- Aluminum

- Copper

- Brass

4. What factors influence the rolling process in a roughing mill?

Factors influencing the rolling process include:

- Roll diameter and shape

- Rolling speed

- Workpiece temperature

- Lubrication

5. What are the safety precautions to follow when operating a roughing mill?

Safety precautions include:

- Wearing appropriate PPE

- Keeping the area clean and free of debris

- Inspecting the mill regularly

- Following proper lockout/tagout procedures

6. How do you maintain a roughing mill?

Regular maintenance includes:

- Lubricating the bearings

- Inspecting the rolls for wear or damage

- Adjusting the roll gap as needed

- Cleaning and inspecting the mill housing

7. Explain the process of setting up a roughing mill for a specific job.

Setting up a roughing mill involves:

- Selecting and installing the appropriate rolls

- Adjusting the roll gap and bearings

- Setting up the mill speed and lubrication system

- Testing the setup with a sample workpiece

8. How do you troubleshoot common problems that occur during the rolling process?

Common problems and solutions include:

- Roll slippage: Adjust roll pressure, check lubrication

- Workpiece cracking: Reduce rolling speed, increase roll gap

- Surface defects: Clean rolls, adjust lubrication

- Mill vibration: Check roll alignment, balance rolls

9. What quality control measures are performed during the rolling process?

Quality control measures include:

- Monitoring workpiece dimensions

- Checking for surface defects

- Testing material properties

- Maintaining records of the rolling process

10. Describe your experience in operating a roughing mill.

In my previous role as a Roughing Mill Operator, I was responsible for:

- Setting up and operating the roughing mill

- Troubleshooting and resolving mill problems

- Maintaining the mill and its components

- Ensuring the production of high-quality rolled products

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roughing Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roughing Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Roughing Mill Operator is responsible for the operation, maintenance, and troubleshooting of a roughing mill, a machine used to shape and reduce the thickness of metal stock. Key responsibilities include:

1. Operating the Roughing Mill

Operating the roughing mill safely and efficiently, ensuring that it is set up correctly and running smoothly.

- Monitoring the mill’s performance and making adjustments as needed.

- Performing routine maintenance tasks to keep the mill running at optimal levels.

2. Troubleshooting and Repairing Mill Issues

Identifying and resolving any issues that arise with the roughing mill, ensuring that it is operating at peak efficiency.

- Performing diagnostic tests to identify the source of problems.

- Replacing worn or damaged parts as needed.

3. Maintaining Mill Equipment

Performing regular maintenance and repairs on the roughing mill and associated equipment, ensuring that it is operating safely and efficiently.

- Lubricating moving parts.

- Calibrating sensors and other control systems.

4. Following Safety Procedures

Adhering to all safety protocols and procedures to ensure a safe work environment for oneself and others.

- Wearing appropriate personal protective equipment.

- Following lockout/tagout procedures.

Interview Tips

To prepare for an interview for a Roughing Mill Operator position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, values, and products or services. Read the job description thoroughly and identify the key requirements and responsibilities of the role.

- Visit the company’s website and social media pages.

- Read industry news and articles to gain insights into the company’s operations.

2. Practice Answering Common Interview Questions

Prepare answers to common interview questions, such as:

- Tell me about your experience operating a roughing mill.

- How do you handle troubleshooting and repairing mill issues?

- What is your approach to maintaining mill equipment?

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Provide specific examples and quantify your accomplishments whenever possible.

- Describe your proficiency in operating and maintaining roughing mills.

- Share examples of successful troubleshooting and repair experiences.

- Highlight your commitment to safety and knowledge of safety protocols.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. Prepare a few questions to ask the interviewer about the company’s operations, the team you would be joining, and the potential for growth and advancement.

- What are the current challenges facing the company’s manufacturing process?

- How does the roughing mill operator role contribute to the overall production goals?

- What opportunities are there for professional development and advancement within the company?

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for the interview. Maintain a positive and confident demeanor throughout the interview.

- Wear business attire or appropriate workwear if requested.

- Be punctual and allow extra time for unexpected delays.

- Exude confidence and enthusiasm during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Roughing Mill Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.