Are you gearing up for an interview for a Round Corner Cutter Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Round Corner Cutter Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

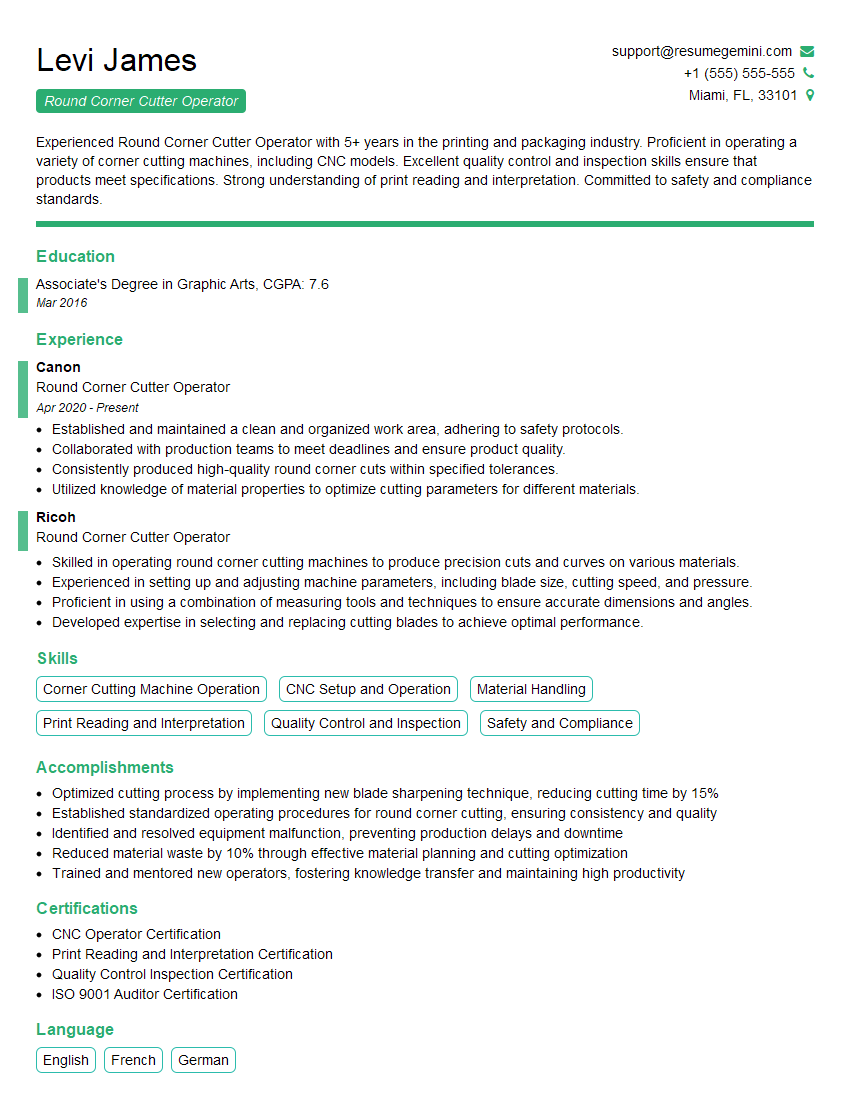

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Round Corner Cutter Operator

1. What are the types of round corner cutting machines and their general applications?

- Manual round corner cutters: These are hand-operated machines that are used for small-scale cutting and finishing operations. They are suitable for cutting a variety of materials, including paper, cardboard, plastic, and leather.

- Electric round corner cutters: These are powered machines that are used for larger-scale cutting operations. They are equipped with a variety of features, such as adjustable cutting depths, automatic feed systems, and dust collection systems.

- Hydraulic round corner cutters: These are high-powered machines that are used for cutting heavy-duty materials, such as metal and wood. They are equipped with powerful hydraulic systems that provide the necessary force to cut through tough materials.

2. What are the safety precautions that must be taken when operating a round corner cutter?

Wearing appropriate safety gear

- Safety glasses: To protect your eyes from flying debris.

- Gloves: To protect your hands from sharp edges.

- Ear protection: To protect your hearing from loud noise.

- Dust mask: To protect your lungs from dust and debris.

Proper machine operation

- Ensure that the machine is properly grounded.

- Never put your hands or fingers near the cutting blade.

- Keep the work area clean and free of debris.

- Never operate the machine while under the influence of alcohol or drugs.

Regular maintenance

- Inspect the machine regularly for any damage or wear and tear.

- Lubricate the machine according to the manufacturer’s instructions.

- Sharpen the cutting blade as needed.

3. How would you set up and calibrate a round corner cutter for a specific cutting job?

- Mount the cutting blade onto the machine.

- Adjust the cutting depth and feed rate according to the thickness and hardness of the material being cut.

- Align the material against the back gauge and side guide.

- Turn on the machine and allow it to reach operating speed.

- Carefully feed the material through the machine, ensuring that it is held firmly against the back gauge and side guide.

- Once the material has been cut, turn off the machine and allow it to come to a complete stop.

- Inspect the cut material for quality and accuracy.

4. What are the different types of cutting blades that can be used on a round corner cutter and when would you use each type?

- High-speed steel (HSS) blades: These blades are made of a hard and durable material that can withstand high cutting speeds. They are suitable for cutting a variety of materials, including paper, cardboard, plastic, and metal.

- Carbide-tipped blades: These blades have a carbide tip that is brazed onto a steel body. They are more durable than HSS blades and can withstand even higher cutting speeds. They are suitable for cutting hard materials, such as metal and wood.

- Diamond-tipped blades: These blades have a diamond tip that is brazed onto a steel body. They are the most durable and long-lasting type of blade and can cut through even the hardest materials. They are suitable for cutting materials such as glass, ceramic, and stone.

5. What are the common maintenance procedures that need to be performed on a round corner cutter?

- Cleaning: The machine should be cleaned regularly to remove dust, debris, and other contaminants. This will help to prevent the machine from becoming damaged and will also help to improve its performance.

- Lubrication: The machine should be lubricated regularly according to the manufacturer’s instructions. This will help to reduce wear and tear on the machine’s components and will also help to extend its lifespan.

- Sharpening: The cutting blade should be sharpened regularly to ensure that it is always sharp and cutting efficiently. A dull blade will require more force to cut through the material, which can lead to premature wear and tear on the machine.

- Adjustments: The machine’s adjustments should be checked regularly to ensure that they are set correctly. Incorrect adjustments can lead to poor cutting quality and can also damage the machine.

6. What are the troubleshooting steps that you would take if the round corner cutter is not cutting properly?

- Check the cutting blade to make sure that it is sharp and free of damage.

- Check the cutting depth and feed rate to make sure that they are set correctly for the material being cut.

- Check the alignment of the material against the back gauge and side guide.

- Make sure that the machine is properly grounded.

- Check the machine’s power supply to make sure that it is receiving the correct voltage and amperage.

- If the problem persists, contact the machine manufacturer for assistance.

7. What are the quality control procedures that you would follow to ensure that the round corner cutter is producing high-quality cuts?

- Inspect the material before cutting to make sure that it is free of defects.

- Set up the machine correctly according to the manufacturer’s instructions.

- Cut a sample piece of material and inspect it for quality.

- Make adjustments to the machine as needed to achieve the desired cut quality.

- Inspect the cut material regularly to ensure that it meets the required specifications.

8. How would you train a new employee on how to operate a round corner cutter?

- Start by showing the new employee the different parts of the machine and explaining their functions.

- Demonstrate how to set up the machine for a specific cutting job.

- Supervise the new employee as they practice cutting different types of materials.

- Provide the new employee with a written training manual for future reference.

- Answer any questions that the new employee may have.

9. What are some of the challenges that you have faced as a round corner cutter operator and how have you overcome them?

- Cutting through thick or hard materials: I have overcome this challenge by using a sharp cutting blade and by adjusting the cutting depth and feed rate accordingly.

- Cutting through materials that are not perfectly aligned: I have overcome this challenge by using a side guide to ensure that the material is aligned properly.

- Cutting through materials that are delicate or easily damaged: I have overcome this challenge by using a light touch and by carefully feeding the material through the machine.

10. What are your career goals and how does this position fit into your plans?

- My career goal is to become a skilled and experienced round corner cutter operator.

- This position would provide me with the opportunity to learn from experienced professionals and to develop my skills in a fast-paced environment.

- I am confident that I can make a valuable contribution to your company and I am eager to learn and grow.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Round Corner Cutter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Round Corner Cutter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Round Corner Cutter Operator operates and maintains round corner cutting machinery in a variety of manufacturing environments. These professionals are responsible for setting up, operating, and maintaining round corner cutting machines, as well as inspecting and packaging finished products. They must have a strong understanding of the operation and maintenance of round corner cutting machinery, as well as the ability to follow instructions and work independently.

1. Set up and operate round corner cutting machinery

Round Corner Cutter Operators are responsible for setting up and operating round corner cutting machinery. This includes loading and unloading materials, setting up the machine according to specifications, and operating the machine to cut materials to the desired shape and size.

- Set up and adjust machine according to work order specifications

- Load and unload materials from the machine

- Operate the machine to cut materials to the desired shape and size

2. Inspect and package finished products

Round Corner Cutter Operators are also responsible for inspecting and packaging finished products. This includes checking products for defects, measuring products to ensure they meet specifications, and packaging products for shipment.

- Inspect finished products for defects

- Measure products to ensure they meet specifications

- Package products for shipment

3. Maintain round corner cutting machinery

Round Corner Cutter Operators are also responsible for maintaining round corner cutting machinery. This includes cleaning and lubricating the machine, replacing worn parts, and troubleshooting any problems that may occur.

- Clean and lubricate the machine

- Replace worn parts

- Troubleshoot any problems that may occur

4. Follow instructions and work independently

Round Corner Cutter Operators must be able to follow instructions and work independently. They must be able to read and understand work orders, and they must be able to work without constant supervision.

- Read and understand work orders

- Work independently without constant supervision

Interview Tips

Preparing for an interview can be nerve-wracking, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the company and the position

The more you know about the company and the position you’re applying for, the better prepared you’ll be to answer questions and make a good impression. Take some time to visit the company’s website, read their annual report, and learn about their products or services. You should also research the specific position you’re applying for, and be prepared to answer questions about your experience and qualifications.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice your answers to these questions in advance, so that you can deliver them confidently and clearly. You can also prepare for specific questions related to the position you’re applying for, such as “What experience do you have in operating round corner cutting machinery?”

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This shows that you’re respectful of the interviewer’s time, and that you’re serious about the position.

4. Be yourself and be enthusiastic

The most important thing is to be yourself and be enthusiastic about the position. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident in your abilities, and let the interviewer know why you’re the best person for the job.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Round Corner Cutter Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.