Feeling lost in a sea of interview questions? Landed that dream interview for Rounding and Backing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Rounding and Backing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

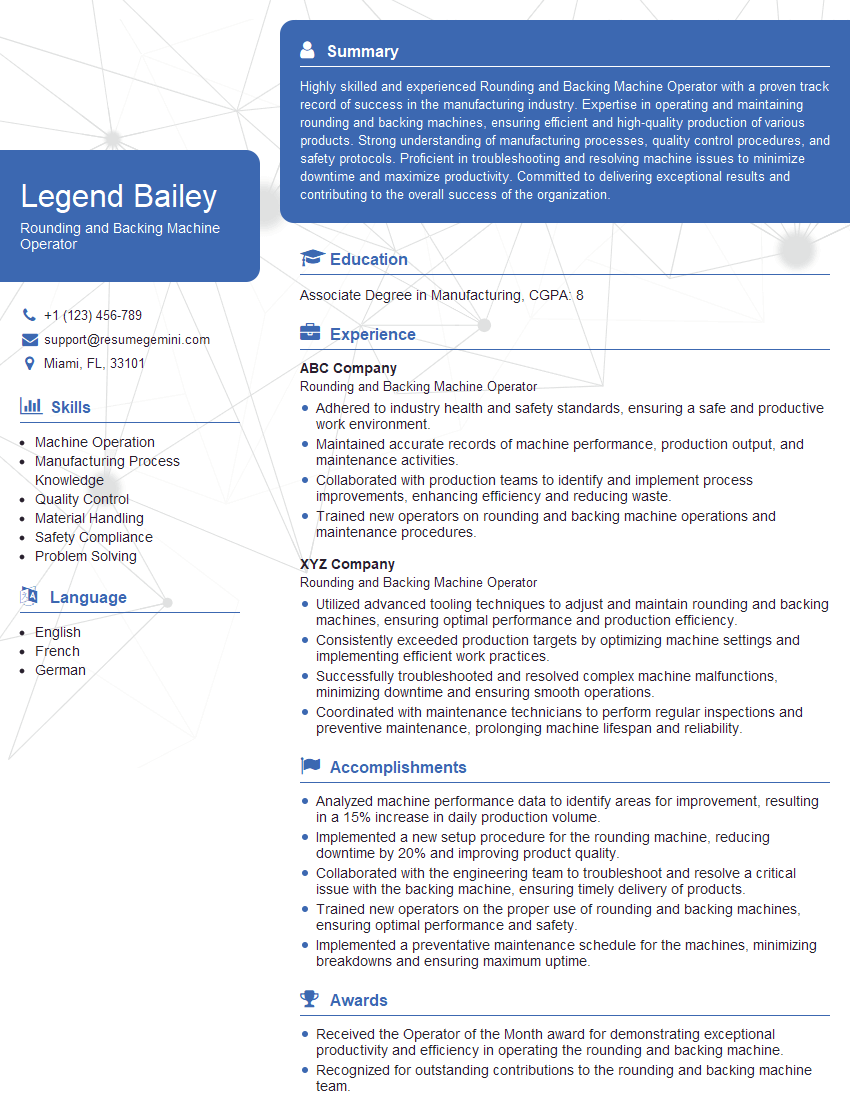

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rounding and Backing Machine Operator

1. How do you ensure that the rounded and backed tubes meet the required specifications?

To ensure that the rounded and backed tubes meet the required specifications, I follow a comprehensive quality control process:

- Inspecting the raw material to confirm its compliance with specifications

- Setting up the rounding and backing machine according to the specifications

- Monitoring the machine during operation to detect any deviations from the desired parameters

- Measuring the finished tubes using precision instruments to verify their dimensions, roundness, and backing quality

- Documenting and recording all inspection results for traceability and quality control

2. Describe your understanding of the rounding and backing process.

Tube Rounding

- Positioning the tube in the rounding machine

- Using rollers to apply pressure and shape the tube into a circular cross-section

- Adjusting the pressure and speed to achieve the desired roundness

Tube Backing

- Placing the rounded tube in the backing machine

- Applying pressure to flatten the tube to a specified thickness

- Maintaining precise control over pressure and temperature to ensure uniform backing

3. How do you handle production issues or malfunctions in the rounding and backing machine?

When production issues or malfunctions occur, I follow a structured troubleshooting process:

- Identifying the problem by observing symptoms and reviewing machine settings

- Consulting with experienced colleagues or supervisors for guidance

- Referencing technical manuals or diagnostic tools to identify potential causes

- Implementing appropriate corrective actions, such as adjusting machine parameters, replacing worn components, or conducting maintenance

- Verifying that the issue has been resolved and that the machine is operating correctly

4. What maintenance procedures do you perform to ensure optimal performance of the rounding and backing machine?

To maintain optimal performance, I conduct regular maintenance procedures:

- Daily cleaning of the machine, including rollers, dies, and sensors

- Weekly lubrication of moving parts to reduce wear and tear

- Monthly inspections of critical components, such as bearings and drive belts

- Scheduled maintenance as per the manufacturer’s recommendations

- Maintaining a logbook to record maintenance activities and identify any potential issues

5. How do you ensure safety while operating the rounding and backing machine?

Safety is paramount in my work. I adhere to the following safety measures:

- Wearing appropriate personal protective equipment, including gloves, safety glasses, and earplugs

- Maintaining a clean and organized work area free of tripping hazards

- Following established lockout/tagout procedures before performing maintenance or repairs

- Being aware of pinch points and moving parts to avoid injuries

- Reporting any unsafe conditions or incidents to supervisors immediately

6. How do you optimize the rounding and backing process for efficiency and quality?

To optimize efficiency and quality, I:

- Analyze production data to identify areas for improvement

- Adjust machine settings to maximize throughput while maintaining quality standards

- Implement lean manufacturing techniques to reduce waste and increase productivity

- Collaborate with other team members to streamline the production process

- Stay updated on industry best practices and new technologies to enhance performance

7. Can you describe the different types of materials that can be rounded and backed using this machine?

The rounding and backing machine I operate can handle various materials, including:

- Aluminum

- Copper

- Steel

- Stainless steel

- Brass

The specific materials that can be processed may vary depending on the machine’s capabilities and the tooling used.

8. What are the common challenges encountered in the rounding and backing process, and how do you overcome them?

Common challenges include:

- Maintaining consistent roundness and backing quality

- Preventing surface defects or scratches

- Adjusting for variations in material thickness

- Meeting tight tolerances

I overcome these challenges through:

- Using precision tooling and maintaining accurate machine settings

- Monitoring the process closely and making adjustments as needed

- Communicating with upstream and downstream processes to ensure compatibility

- Seeking guidance from experienced colleagues or supervisors

9. How do you ensure that the rounded and backed tubes meet the required surface finish specifications?

To achieve the desired surface finish, I:

- Select the appropriate tooling and abrasives

- Adjust the machine’s settings to optimize surface quality

- Monitor the process closely and make adjustments as needed

- Inspect the finished tubes using a microscope or other instruments to verify the surface finish

- Document the results and make adjustments to the process as necessary

10. How do you stay updated on the latest advancements and best practices in the rounding and backing industry?

To stay current, I:

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Network with other professionals in the field

- Participate in online forums and discussion groups

- Seek opportunities for training and professional development

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rounding and Backing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rounding and Backing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rounding and Backing Machine Operator is responsible for operating and maintaining a rounding and backing machine, that produces round or rectangular products by pressing and shaping dough or other food products.

1. Machine Operation:

Operate rounding and backing machines to round or shape dough or other food products as required.

- Set up and adjust machine according to production specifications.

- Monitor machine operation, make necessary adjustments, and ensure smooth operation.

2. Dough Preparation and Shaping:

Prepare dough or other food products for rounding and backing process.

- Weigh and measure ingredients and mix according to specified recipes.

- Proof or ferment dough as required to achieve desired texture and consistency.

- Divide and round dough or shape other food products into desired shapes and sizes.

3. Quality Control and Inspection:

Inspect rounded or backed products to ensure they meet quality standards.

- Check product weight, size, and overall appearance.

- Identify and reject defective products or those that do not meet specifications.

4. Equipment Maintenance and Sanitation:

Maintain and clean rounding and backing machines to ensure optimal operation.

- Clean and sanitize machines and work area regularly to prevent contamination.

- Inspect and lubricate machine components as scheduled.

- Perform minor repairs and adjustments to keep machines in good working order.

Interview Tips

To ace an interview for a Rounding and Backing Machine Operator position, it is crucial to prepare effectively and demonstrate your knowledge and skills.

1. Research the Company and Role:

Research the company’s industry, products or services, and its reputation.

- Review the job description and make note of required skills and responsibilities.

- Visit the company’s website and social media pages to gather information.

2. Highlight Relevant Skills and Experience:

Emphasize your experience operating and maintaining rounding and backing machines.

- Quantify your accomplishments using specific metrics and results.

- Discuss your knowledge of dough preparation, shaping techniques, and quality control processes.

3. Prepare for Common Interview Questions:

Anticipate questions related to your technical skills, attention to detail, and ability to work in a fast-paced environment.

- Sample Interview Question : “Describe your experience in troubleshooting and resolving machine malfunctions.”

- Sample Interview Question : “How do you ensure the quality and consistency of rounded and backed products?”

4. Demonstrate Passion for the Role:

Express your enthusiasm for working in the food industry and your interest in the specific role of a Rounding and Backing Machine Operator.

- Explain what motivates you about the position and why you are a suitable candidate.

- Share your understanding of the role’s importance in the production process.

5. Practice and Prepare Questions:

Practice answering questions and prepare a few insightful questions to ask the interviewer.

- Sample Question to Ask: “What are the company’s key performance indicators for this position?”

- Sample Question to Ask: “Can you describe the company’s training and development programs for employees?”

Next Step:

Now that you’re armed with the knowledge of Rounding and Backing Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rounding and Backing Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini