Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rounding Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

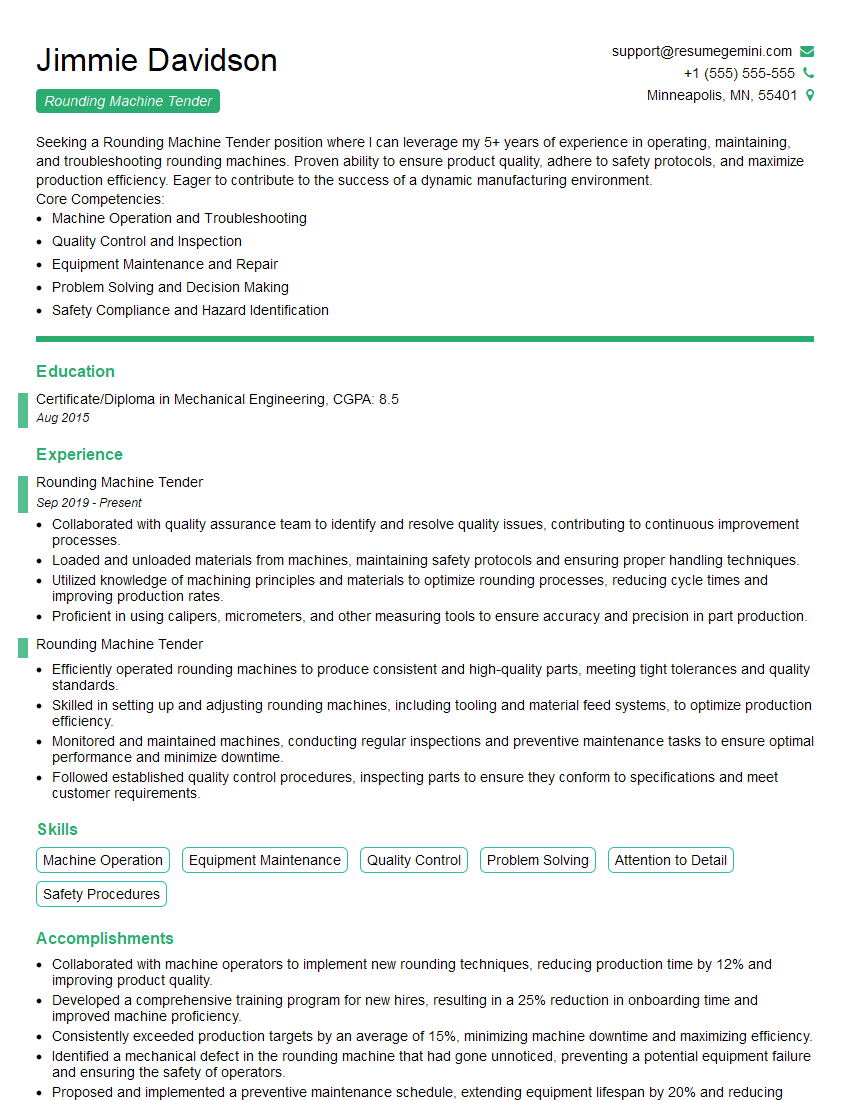

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rounding Machine Tender

1. Describe the process of rounding machine operations and the key quality control points during the process.

The process of rounding machine operations typically involves the following steps:

- Loading the machine with the material to be rounded.

- Setting the machine parameters, such as the speed and pressure of the rounding process.

- Initiating the rounding process.

- Monitoring the rounding process and making adjustments as needed.

- Unloading the rounded material from the machine.

Key quality control points during the rounding process include:

- The accuracy of the rounding process.

- The surface finish of the rounded material.

- The dimensional accuracy of the rounded material.

- The hardness of the rounded material.

- The strength of the rounded material.

2. Explain how to troubleshoot common problems that may arise during rounding machine operations.

Troubleshooting common problems during rounding machine operations

- Problem: The machine is not rounding the material properly.

- Possible cause: The machine parameters are not set correctly.

- Solution: Check the machine parameters and make adjustments as needed.

- Problem: The material is not being loaded into the machine properly.

- Possible cause: The material is not the correct size or shape.

- Solution: Check the material and make sure that it is the correct size and shape.

- Problem: The machine is making a lot of noise.

- Possible cause: The machine is not lubricated properly.

- Solution: Lubricate the machine according to the manufacturer’s instructions.

3. Describe the importance of preventive maintenance for rounding machines.

Preventive maintenance is important for rounding machines because it helps to prevent problems from occurring in the first place. By regularly inspecting and servicing the machine, you can identify and fix potential problems before they cause downtime. This can help to extend the life of the machine and reduce the risk of costly repairs.

Some of the benefits of preventive maintenance for rounding machines include:

- Reduced downtime

- Increased machine life

- Lower repair costs

- Improved safety

- Increased productivity

4. How do you ensure that the rounded products meet the required specifications?

To ensure that the rounded products meet the required specifications, I follow a number of steps:

- I first inspect the material to be rounded to make sure that it is the correct size and shape.

- I then set the machine parameters according to the manufacturer’s instructions.

- I initiate the rounding process and monitor it closely.

- Once the rounding process is complete, I inspect the rounded products to make sure that they meet the required specifications.

- I also keep a record of all of the rounding parameters and the results of the inspections.

5. What are the safety precautions that should be taken when operating a rounding machine?

When operating a rounding machine, it is important to take the following safety precautions:

- Wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Keep the work area clean and free of debris.

- Be aware of the location of all controls and emergency stops.

- Never operate the machine if it is damaged or malfunctioning.

- Follow all of the manufacturer’s instructions for safe operation.

6. Describe the different types of rounding machines and their applications.

There are two main types of rounding machines: manual rounding machines and automatic rounding machines.

Manual rounding machines

Manual rounding machines are operated by hand and are typically used for small-scale rounding operations.

Automatic rounding machines

Automatic rounding machines are powered by a motor and are typically used for large-scale rounding operations.

Both types of rounding machines can be used for a variety of applications, including:

- Rounding off the edges of metal parts

- Rounding off the corners of plastic parts

- Rounding off the edges of wood parts

- Rounding off the corners of glass parts

7. What are the key factors to consider when selecting a rounding machine?

When selecting a rounding machine, it is important to consider the following factors:

- The type of material to be rounded

- The size and shape of the material to be rounded

- The required accuracy of the rounding process

- The desired production rate

- The available budget

8. How do you maintain the accuracy of a rounding machine?

To maintain the accuracy of a rounding machine, it is important to:

- Regularly calibrate the machine according to the manufacturer’s instructions.

- Use the correct tooling for the material being rounded.

- Inspect the rounded products regularly to ensure that they meet the required specifications.

- Keep the machine clean and free of debris.

- Follow all of the manufacturer’s instructions for maintenance and operation.

9. What are the common causes of rounding machine downtime, and how can they be prevented?

Common causes of rounding machine downtime include:

- Improperly set up machine

- Dull or damaged tooling

- Material that is too hard or too soft

- Improperly maintained machine

- Operator error

Downtime can be prevented by:

- Properly setting up the machine

- Using sharp and undamaged tooling

- Using the correct material for the machine

- Properly maintaining the machine

- Training operators on the proper operation of the machine

10. How do you improve the efficiency of a rounding machine?

The efficiency of a rounding machine can be improved by:

- Using the correct tooling for the material being rounded

- Optimizing the machine settings

- Automating the rounding process

- Reducing downtime

- Training operators on the proper operation of the machine

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rounding Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rounding Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rounding Machine Tenders are responsible for the operation and maintenance of rounding machines, which round corners of various materials such as paper, plastic, and metal.

1. Machine Operation

Tenders are expected to set up, calibrate, and operate rounding machines. This includes adjusting machine settings based on material specifications and ensuring that the machine is producing rounded corners that meet the required dimensions and quality standards.

- Loading materials into the machine and monitoring the rounding process.

- Inspecting the rounded corners for accuracy and quality, making adjustments as needed.

2. Machine Maintenance

Tenders are responsible for maintaining their machines in optimal condition. This includes regular cleaning and lubrication, performing minor repairs, and monitoring machine performance to identify any potential issues.

- Changing worn or damaged components as needed.

- Keeping a maintenance log to document machine performance and repairs.

3. Quality Control

Tenders are required to maintain the quality of the rounded products. This includes ensuring that the rounded corners meet the required specifications, inspecting outgoing products for defects, and identifying and correcting any quality issues promptly.

- Testing and inspecting materials before and after rounding to ensure accuracy.

- Working with quality control personnel to investigate and resolve quality issues.

4. Safety Compliance

Tenders must strictly adhere to safety protocols to ensure a safe working environment. This includes wearing appropriate safety gear, following safety procedures, and maintaining a clean and organized work area.

- Identifying and reporting potential safety hazards to supervisors immediately.

- Participating in safety training programs and staying up-to-date on safety regulations.

Interview Tips

Preparing for an interview for a Rounding Machine Tender position requires a combination of research, practice, and confidence. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Take time to research the company you’re applying to, including their products, services, and company culture. Also, learn about the industry in which they operate, including trends, major players, and industry challenges.

- Check the company website, LinkedIn profile, and industry publications for information.

- This knowledge will demonstrate your interest in the company and the position.

2. Practice Your Answers

Anticipate common interview questions and practice answering them out loud. This helps you organize your thoughts, speak confidently, and reduce nervousness during the actual interview.

- Prepare answers to questions about your experience, skills, and knowledge related to rounding machines.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

3. Highlight Your Skills and Experience

During the interview, emphasize your relevant skills and experience that align with the job responsibilities. Quantify your accomplishments with specific metrics and examples whenever possible.

- Review the job description carefully and identify the key skills and qualifications.

- Provide concrete examples of how your past experience has equipped you for the role.

4. Show Your Enthusiasm

Express your genuine interest in the position and the company. Let the interviewer know why you’re excited about the opportunity and how your skills and qualifications would benefit their team.

- Research the company’s products or services and explain how your experience can contribute to their success.

- Be enthusiastic but professional, and avoid sounding overeager or desperate.

5. Ask Insightful Questions

At the end of the interview, asking thoughtful questions shows your engagement and interest in the position and the company. Prepare a few questions that demonstrate your understanding of the role and your desire to learn more.

- Ask about the company’s growth plans or industry trends.

- Inquire about training and development opportunities within the organization.

6. Follow Up

After the interview, send a thank-you note to the interviewer within 24 hours. Express your appreciation for their time and reiterate your interest in the position. You can also use this opportunity to clarify any points or provide additional information if needed.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rounding Machine Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.