Are you gearing up for a career in Roving Changer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Roving Changer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

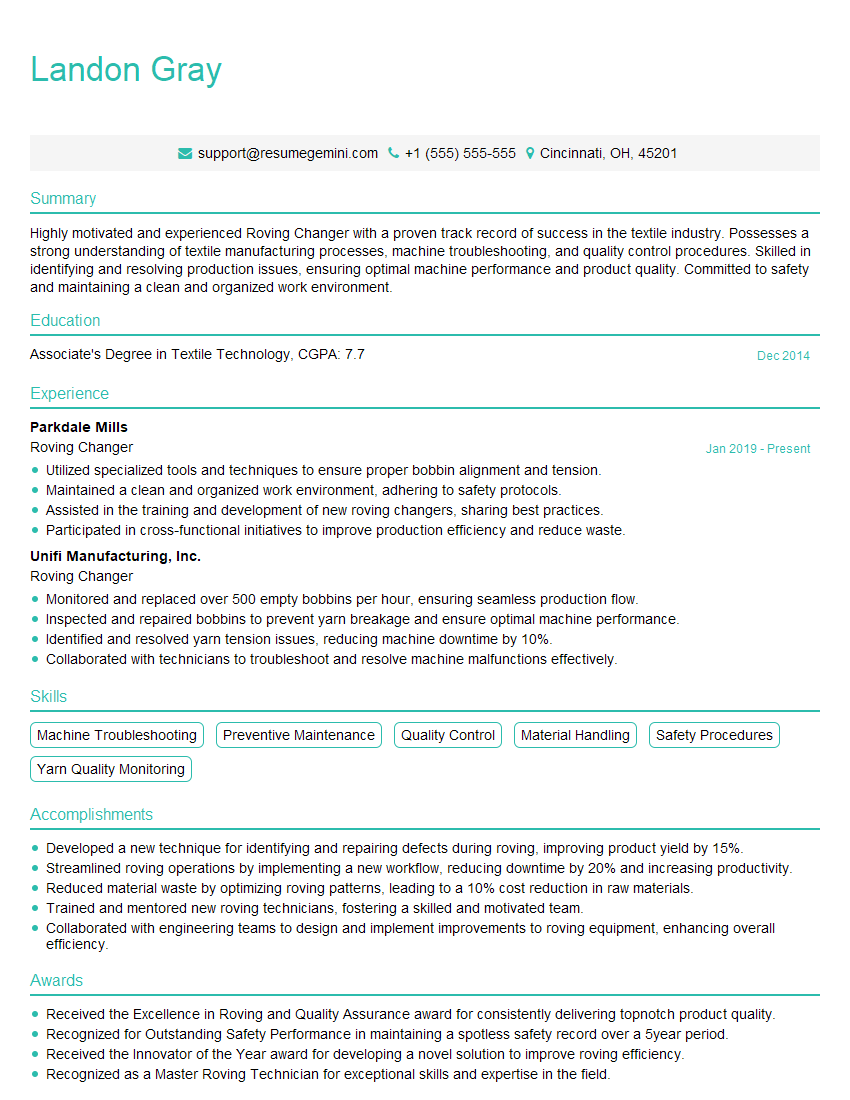

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roving Changer

1. Which methods do you employ to identify roving defects in textile production?

To identify roving defects in textile production, I employ a comprehensive approach that includes:

- Regular visual inspection of the roving during production

- Analysis of roving yarn properties, such as strength, elongation, and hairiness

- Utilization of specialized testing equipment, such as the Uster Tester and Evenness Tester

- Review of production parameters, including machine settings and process conditions

- Collaboration with quality control personnel to identify and rectify the root causes of defects

2. Describe the key factors that influence the quality of roving.

Fiber Properties:

- Fiber length and fineness

- Fiber strength and elongation

- Fiber cleanliness and impurities

Process Parameters:

- Carding and combing settings

- Drafting ratio and speed

- Twist level and direction

- Roving bobbin tension

Machine Conditions:

- Rollers and guides alignment

- Temperature and humidity control

- Regular maintenance and calibration

3. How do you ensure the consistency and uniformity of roving throughout the production process?

To ensure the consistency and uniformity of roving throughout the production process, I implement the following measures:

- Establish and adhere to strict process parameters

- Regularly calibrate and maintain roving machinery

- Monitor and control environmental conditions, such as temperature and humidity

- Implement quality control procedures at each stage of the process

- Use statistical process control techniques to identify and eliminate variations

4. Explain the role of drafting in roving production and how it affects roving quality.

Drafting plays a crucial role in roving production and significantly impacts roving quality. It involves attenuating and aligning fibers to create a continuous strand with the desired thickness and properties:

- Fiber Alignment: Drafting aligns fibers parallel to each other, improving roving strength and evenness.

- Reduction in Thickness: By attenuating the roving, drafting reduces its thickness and increases its length.

- Improved Tensile Strength: Aligned fibers provide greater resistance to breakage, resulting in stronger roving.

- Yarn Quality: Proper drafting ensures that subsequent yarn production processes, such as spinning and weaving, are more efficient and produce high-quality yarn.

5. How do you handle and store roving to prevent damage or contamination?

To prevent damage or contamination of roving, I adhere to the following handling and storage practices:

- Use proper handling equipment to avoid tangling or breakage

- Store roving in clean, dry, and well-ventilated areas

- Protect roving from direct sunlight and excessive heat

- Implement first-in, first-out inventory management to prevent aging

- Train personnel on proper handling and storage techniques

6. Describe the maintenance procedures you perform on roving machinery.

To ensure optimal performance and longevity of roving machinery, I conduct the following maintenance procedures:

- Regular Cleaning: Remove dust, fiber accumulation, and other contaminants from all machine components

- Lubrication: Apply lubricants to moving parts according to manufacturer’s specifications

- Alignment and Tension Checks: Inspect and adjust rollers, guides, and belts to ensure proper alignment and tension

- Safety Checks: Verify the functionality of safety devices and guards

- Preventive Maintenance: Perform scheduled inspections and replacements of critical components to prevent breakdowns

7. How do you troubleshoot common roving production defects?

To troubleshoot common roving production defects effectively, I follow a systematic approach:

- Identify the Defect: Examine the roving visually and analyze its properties to determine the specific defect.

- Trace the Source: Review process parameters, machine settings, and raw material quality to identify the potential cause.

- Implement Corrective Measures: Based on the identified cause, make necessary adjustments to process parameters, machine settings, or raw material selection.

- Monitor Improvements: Regularly inspect the roving after implementing corrective measures to ensure the defect has been eliminated.

- Root Cause Analysis: Investigate the underlying factors that contributed to the defect to prevent its recurrence.

8. Describe the quality control measures you implement to ensure the production of high-quality roving.

To ensure the production of high-quality roving, I implement the following quality control measures:

- In-Process Monitoring: Regularly inspect roving during production and conduct tests to assess its properties.

- Statistical Process Control: Use statistical techniques to monitor process stability and identify deviations from desired specifications.

- End-Product Testing: Perform comprehensive tests on finished roving to verify its compliance with customer requirements.

- Supplier Qualification: Evaluate and approve suppliers of raw materials to ensure consistency and quality.

- Continuous Improvement: Regularly review quality data and implement improvements to enhance roving quality.

9. Explain the importance of teamwork and communication in maintaining a high-performing roving production team.

Teamwork and communication are crucial for maintaining a high-performing roving production team. Effective collaboration among team members ensures:

- Efficient Problem-Solving: Sharing knowledge and perspectives facilitates quicker and more effective problem-solving.

- Improved Decision-Making: Team discussions lead to more informed and well-rounded decisions.

- Knowledge Transfer: Team members can learn from each other’s experiences and expertise.

- Increased Productivity: Clear communication and coordination reduce misunderstandings and delays.

- Positive Work Environment: Teamwork fosters a sense of camaraderie and support within the team.

10. How do you stay updated with the latest advancements in roving production technology?

To stay updated with the latest advancements in roving production technology, I employ the following strategies:

- Attend Industry Conferences and Exhibitions: Participate in events where new technologies and innovations are showcased.

- Read Technical Journals and Publications: Stay informed about research and developments in the field.

- Network with Industry Experts: Connect with professionals in the industry to exchange knowledge and insights.

- Explore Online Resources: Utilize online platforms and databases to access technical information and best practices.

- Attend Training and Workshops: Seek opportunities for professional development and training to enhance my technical skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roving Changer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roving Changer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Roving Changer plays a vital role in the production process of the textile and manufacturing industry. Their primary responsibilities encompass all aspects of changing and maintaining spinning frames to ensure efficient and smooth operation.1. Machine Operation and Maintenance

Operate multiple spinning frames simultaneously, ensuring optimal production output.

- Monitor and adjust machine settings to optimize yarn quality and minimize defects.

- Perform routine maintenance tasks, such as cleaning, lubrication, and minor repairs.

2. Yarn Quality Control

Continuously inspect yarn quality during production to identify and address any issues.

- Identify and remove yarn defects, such as breaks, knots, and unevenness.

- Adjust machine settings and processes to maintain consistent yarn quality.

3. Production Monitoring and Optimization

Monitor production rates and identify areas for improvement.

- Maintain production records and report any deviations from standard operating procedures.

- Collaborate with supervisors to implement process improvements and increase efficiency.

4. Safety and Compliance

Adhere to safety protocols and maintain a clean and organized work environment.

- Follow proper lifting techniques and use appropriate safety gear.

- Ensure compliance with all applicable environmental and safety regulations.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some key tips to help you ace your interview for a Roving Changer position:

1. Research the Company and Role

Familiarize yourself with the company’s background, values, and the specific requirements of the Roving Changer role. This demonstrates your interest in the position and the organization.

- Visit the company’s website and social media pages.

- Reach out to your network to connect with current or former employees.

2. Highlight Relevant Skills and Experience

Emphasize your qualifications that align with the job description. Quantify your accomplishments whenever possible to demonstrate your impact.

- Focus on your experience operating and maintaining spinning frames.

- Provide examples of how you have improved yarn quality and increased production efficiency.

3. Demonstrate a Strong Work Ethic

Convey your dedication to hard work and attention to detail. Emphasize your ability to work independently and as part of a team.

- Share examples of your commitment to safety and quality control.

- Discuss your willingness to work flexible hours and meet production demands.

4. Prepare Common Interview Questions

Practice answering common interview questions to build confidence and prepare for potential scenarios.

- “Tell me about your experience as a Roving Changer.”

- “How do you ensure yarn quality and minimize defects?”

- “Describe a situation where you had to troubleshoot and resolve a production issue.”

5. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately and arrive for your interview punctually to demonstrate your professionalism and respect for the interviewers.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Roving Changer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Roving Changer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.