Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Roving Frame Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Roving Frame Tender so you can tailor your answers to impress potential employers.

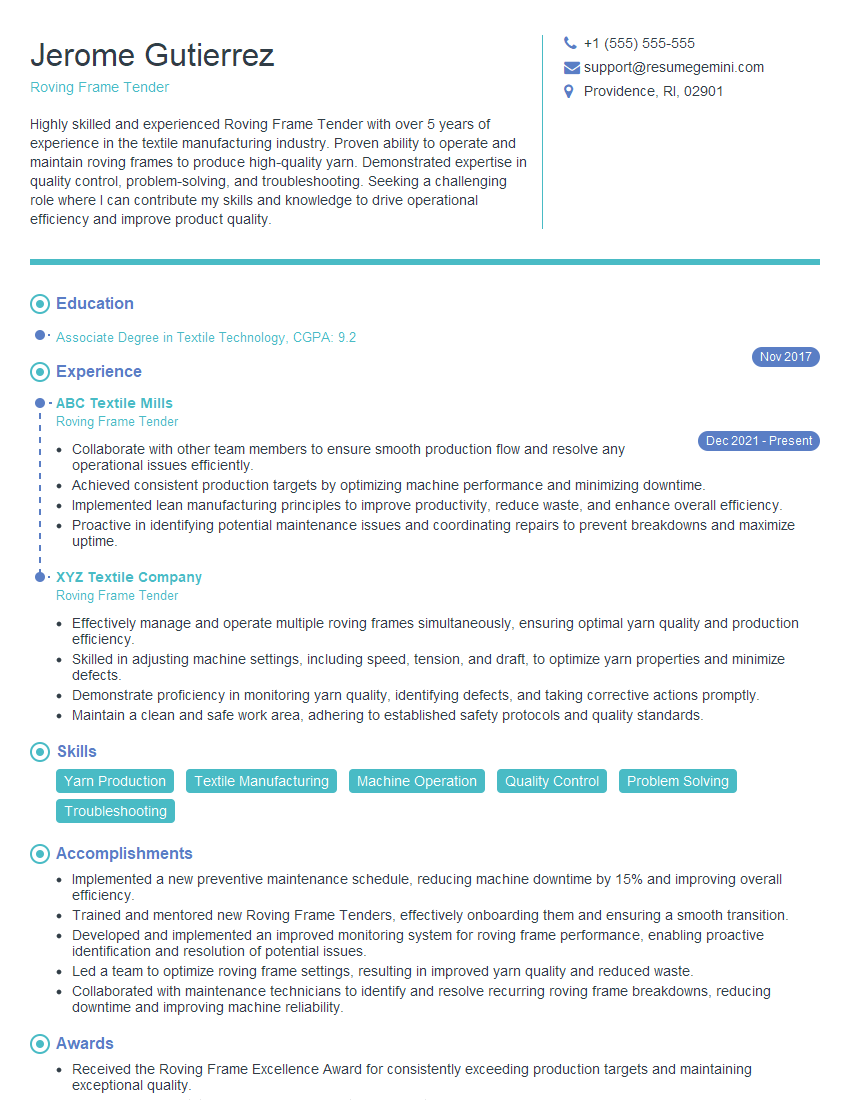

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roving Frame Tender

1. Explain the process of roving frame in textile manufacturing?

The roving frame is a machine used in textile manufacturing to prepare the roving, which is a continuous strand of fibers that is used to create yarn. The process of roving involves several steps:

- Lap preparation: The first step is to prepare the lap, which is a large bundle of fibers. The lap is placed on the creel of the roving frame.

- Drawing: The fibers are then drawn out of the lap and passed through a series of rollers. This process aligns the fibers and removes any impurities.

- Roving: The drawn fibers are then twisted together to form the roving. The roving is wound onto a bobbin.

- Conditioning: The roving is then conditioned to improve its strength and elasticity. This is done by passing the roving through a heated chamber.

2. Describe the different types of roving frames?

Mechanical Roving Frame

- Uses mechanical components to draft and twist the fibers.

- Less precise and efficient compared to electronic roving frames.

Electronic Roving Frame

- Employs electronic sensors and actuators for precise control of drafting and twisting.

- Produces higher quality roving with better uniformity and consistency.

- More advanced and expensive than mechanical roving frames.

3. What are the key parameters to monitor and control while operating a roving frame?

The key parameters to monitor and control while operating a roving frame include:

- Draft: The ratio of the input fiber thickness to the output roving thickness.

- Twist: The number of twists per unit length of the roving.

- Roving tension: The tension applied to the roving as it is wound onto the bobbin.

- Roving quality: The uniformity, consistency, and strength of the roving.

4. How do you troubleshoot common problems that occur during roving?

Common problems that occur during roving and their troubleshooting steps include:

- Roving breakage: Check for worn or damaged rollers, excessive tension, or uneven fiber distribution.

- Roving unevenness: Adjust the draft settings, check for roller wear, or calibrate the electronic sensors.

- Roving hairiness: Reduce the draft, increase the twist, or check for fiber contamination.

- Roving weak: Increase the twist, check for proper roving conditioning, or adjust the draft settings.

5. What are the safety precautions to follow when operating a roving frame?

The safety precautions to follow when operating a roving frame include:

- Wear appropriate protective clothing: Safety glasses, gloves, and earplugs.

- Keep the work area clean: Remove any loose fibers or debris.

- Be aware of moving parts: Avoid touching or reaching into the machine while it is operating.

- Follow proper lockout/tagout procedures: When servicing or repairing the machine.

- Report any malfunctions or safety hazards immediately: To ensure prompt maintenance and prevent accidents.

6. How do you maintain a roving frame to ensure optimal performance?

To maintain a roving frame for optimal performance, regular maintenance tasks include:

- Cleaning: Remove dust and debris from the machine regularly.

- Lubrication: Lubricate moving parts as per the manufacturer’s recommendations.

- Roller inspection: Check rollers for wear or damage and replace as necessary.

- Calibration: Calibrate electronic sensors and adjust settings to ensure precision.

- Preventive maintenance: Schedule regular inspections and repairs to identify and address potential issues early on.

7. Explain the role of draft in roving frame operation?

Draft in a roving frame refers to the ratio of the thickness of the input sliver to the thickness of the output roving. It plays a crucial role in determining the properties of the roving, such as its strength, elongation, and hairiness.

- High Draft: Produces finer roving with higher strength and less hairiness.

- Low Draft: Produces coarser roving with lower strength and more hairiness.

8. Describe the process of sliver preparation before roving?

Before roving, the sliver undergoes several preparation steps to ensure its quality and suitability for the roving process:

- Carding: Removes impurities and aligns the fibers.

- Drawing: Attenuates and aligns the fibers to improve fiber distribution.

- Combing (Optional): Removes short fibers and further aligns the fibers.

- Sliver Lap Formation: The prepared sliver is formed into a lap for feeding into the roving frame.

9. How do you determine the appropriate twist level for roving?

The appropriate twist level for roving depends on several factors, including:

- Fiber Type and Length: Different fibers require different twist levels based on their properties.

- Yarn Count: Higher yarn counts require higher twist levels.

- End Use: The intended use of the yarn influences the required twist level.

- Twist Tester: A twist tester is used to measure and adjust the twist level to meet the desired specifications.

10. Explain the importance of roving conditioning?

Conditioning the roving is essential to enhance its quality and performance during subsequent yarn production processes. Conditioning involves subjecting the roving to controlled temperature and humidity conditions:

- Strength and Elasticity: Conditioning improves the strength and elasticity of the roving, reducing breakage during spinning.

- Moisture Regain: It ensures consistent moisture content, which is crucial for optimal yarn formation.

- Handling and Storage: Conditioning makes the roving easier to handle and store, preventing static buildup and tangling.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roving Frame Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roving Frame Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roving Frame Tenders play a crucial role in the textile industry, operating and maintaining roving frames to produce high-quality roving for subsequent textile manufacturing processes.

1. Machine Operation and Maintenance

Tenders are responsible for the efficient operation of roving frames. This includes:

- Monitoring and adjusting machine settings to optimize roving quality

- Performing routine maintenance tasks, such as cleaning, lubrication, and minor repairs

2. Quality Control

Tenders are responsible for ensuring the quality of the roving produced by the frames.

- Inspecting roving for defects, such as breaks, unevenness, or impurities

- Adjusting machine settings and rectifying any issues that affect roving quality

3. Material Handling

Tenders handle various materials during the roving process.

- Loading and unloading roving bobbins and slivers onto and from the roving frame

- Maintaining an organized and efficient work area

4. Production Monitoring

Tenders monitor the production process to ensure efficiency and identify any potential issues.

- Observing machine performance and recording production data

- Identifying and reporting any malfunctions or breakdowns

Interview Tips

Interview preparation is essential to ace a job interview for a Roving Frame Tender position. Here are some tips and hacks to help you stand out:

1. Research the Company and Role

Before the interview, thoroughly research the company and the specific responsibilities of a Roving Frame Tender within that company. This will help you tailor your answers to the interviewer’s questions and demonstrate your understanding of the role.

- Visit the company website to learn about their products, services, and values.

- Read job descriptions and reviews to gain insights into the expectations and challenges of the role.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job responsibilities of a Roving Frame Tender. Use specific examples to illustrate your abilities.

- Highlight your experience operating machinery and performing maintenance tasks.

- Provide examples of how you have ensured quality control in previous positions.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. This will help you respond confidently and clearly.

- Questions related to your experience operating roving frames

- Questions about your quality control procedures

4. Prepare Questions for the Interviewer

Preparing questions to ask the interviewer shows that you are engaged and interested in the position.

- Ask about the company’s goals and growth plans.

- Inquire about the expectations for the Roving Frame Tender role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Roving Frame Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!