Feeling lost in a sea of interview questions? Landed that dream interview for Roving Weight Gauger but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Roving Weight Gauger interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

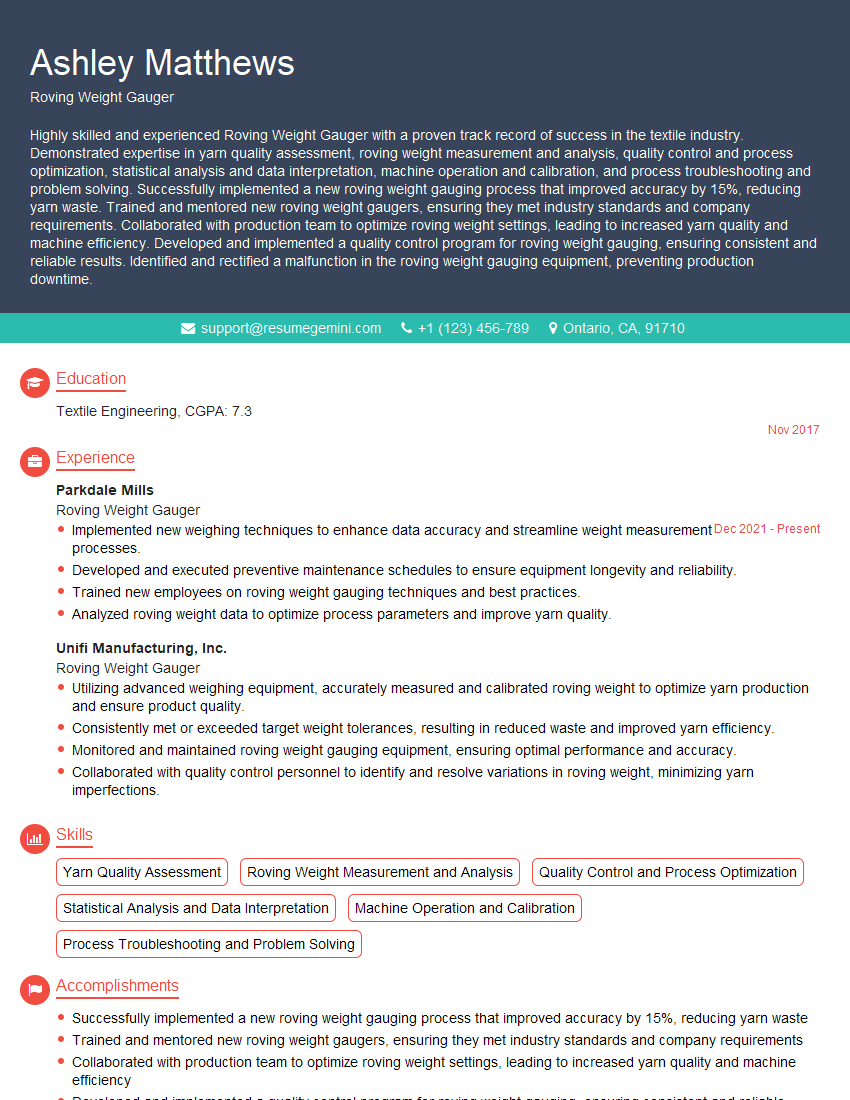

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roving Weight Gauger

1. How would you ensure that the roving weight gauge you are using is accurate?

To ensure the accuracy of the roving weight gauge, I would implement the following steps:

- Regular calibration: Regularly calibrate the gauge against a known weight standard to maintain its precision and reliability.

- Preventive maintenance: Perform routine maintenance and inspections of the gauge, checking for any wear or damage that could affect its accuracy.

- Proper handling and storage: Handle and store the gauge carefully to prevent any knocks or mishandling that could compromise its calibration.

2. When measuring the roving weight, what factors can affect the accuracy of the results?

External factors

- Environmental conditions: Temperature, humidity, and dust can all influence the readings, so controlled conditions are essential.

- Fiber type: Different fiber types have varying densities and moisture content, which can affect the weight measurements.

Instrument factors

- Calibration: An improperly calibrated gauge will provide inaccurate readings.

- Maintenance: Worn or damaged components can compromise accuracy.

3. How do you interpret the data obtained from the roving weight gauge and determine if the weight is within acceptable limits?

To interpret the data from the roving weight gauge and determine if the weight is within acceptable limits, I would:

- Compare the measured weight to the specified target weight: Calculate the deviation from the target and assess if it falls within the allowable tolerance range.

- Analyze trends: Monitor weight measurements over time to identify any gradual changes or deviations from the norm.

- Consider process parameters: Take into account factors such as roving tension, spinning speed, and raw material quality that could influence the weight.

4. What actions would you take if you discovered that the roving weight was consistently outside of the acceptable limits?

If I discovered that the roving weight was consistently outside of the acceptable limits, I would take the following actions:

- Identify the root cause: Investigate potential factors such as equipment malfunction, process variations, or raw material issues.

- Implement corrective measures: Depending on the identified cause, implement appropriate solutions such as adjusting settings, calibrating equipment, or addressing raw material quality.

- Monitor the results: Continuously monitor the roving weight measurements to ensure that the corrective actions have resolved the issue and the weight is now within acceptable limits.

5. How would you ensure that the roving weight gauging process is consistent and reliable?

To ensure consistency and reliability in the roving weight gauging process, I would implement the following measures:

- Standardized operating procedures: Establish clear and documented procedures for the gauging process, including calibration, maintenance, and data interpretation.

- Training and certification: Train operators on the proper use and maintenance of the gauging equipment and ensure they are certified as competent.

- Regular audits and monitoring: Conduct regular audits and monitoring of the gauging process to identify any deviations from standard practices.

6. How do you prioritize your responsibilities as a Roving Weight Gauger?

I prioritize my responsibilities as a Roving Weight Gauger based on the following factors:

- Accuracy and reliability: Ensuring the accuracy and reliability of weight measurements is my top priority, as it directly impacts the quality of the final yarn product.

- Timeliness: Providing timely weight measurements to support production processes without compromising accuracy.

- Process optimization: Working closely with production teams to identify and implement process improvements that enhance the efficiency and effectiveness of roving weight gauging.

7. How do you maintain a clean and organized work area?

To maintain a clean and organized work area, I adhere to the following practices:

- Regular cleaning: Regularly clean the roving weight gauging equipment and surrounding area to remove any dust, fibers, or debris.

- Designated storage: Have designated storage spaces for equipment, materials, and documentation to prevent clutter.

- Good housekeeping practices: Encourage good housekeeping practices among colleagues to maintain a clean and organized work environment.

8. How do you stay up-to-date with industry best practices and advancements in roving weight gauging?

To stay up-to-date with industry best practices and advancements in roving weight gauging, I engage in the following activities:

- Attend industry conferences: Participate in industry conferences and workshops to learn about new technologies, techniques, and research findings.

- Read trade publications: Regularly read trade publications and technical journals to stay informed about the latest developments in the field.

- Network with colleagues: Connect with other roving weight gaugers and industry professionals to share knowledge and best practices.

9. How do you handle and resolve conflicts or disagreements with colleagues?

When handling conflicts or disagreements with colleagues, I prioritize the following steps:

- Maintain a professional demeanor: Approach the situation with respect and professionalism, even if there are strong disagreements.

- Communicate effectively: Engage in open and honest communication to clearly express concerns and perspectives.

- Identify common ground: Focus on identifying areas of agreement and shared goals to find mutually acceptable solutions.

10. How do you ensure that your work meets the quality standards required for the production of high-quality yarn?

To ensure that my work meets the quality standards required for the production of high-quality yarn, I implement the following measures:

- Adherence to specifications: Strictly adhere to established quality specifications and industry standards for roving weight gauging.

- Rigorous data recording: Maintain accurate and detailed records of weight measurements, including any deviations or corrective actions taken.

- Regular self-assessment: Regularly review my work to identify areas for improvement and ensure continuous quality enhancement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roving Weight Gauger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roving Weight Gauger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Roving Weight Gauger is responsible for ensuring the accuracy and consistency of the weight of roving bobbins. The weight of the roving bobbins must conform to the specifications of the customer. The primary responsibilities include:1. Collecting and Recording Data

The Roving Weight Gauger collects data on the weight of roving bobbins. The data is recorded and used to track the weight of the bobbins over time. This data is used to identify trends and make adjustments to the roving process as needed.

2. Inspecting and Testing Roving Bobbins

The Roving Weight Gauger inspects and tests roving bobbins to ensure that they meet the customer’s specifications. The inspection process includes checking the weight, diameter, and length of the bobbins. The bobbins are also tested for strength and durability.

3. Maintaining and Calibrating Equipment

The Roving Weight Gauger maintains and calibrates the equipment used to weigh and test roving bobbins. The equipment is calibrated on a regular basis to ensure that it is accurate and reliable. The Roving Weight Gauger also performs routine maintenance on the equipment to prevent breakdowns.

4. Analyzing Data and Reporting Results

The Roving Weight Gauger analyzes the data collected from the weighing and testing process. The data is used to identify trends and make recommendations for improvements to the roving process. The Roving Weight Gauger also prepares reports on the weight and quality of the roving bobbins.

Interview Tips

An interview for a position as a Roving Weight Gauger can be a daunting experience. However, by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before your interview, take the time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor.

2. Prepare Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Take the time to prepare your answers to these questions in advance. This will help you to feel more confident and prepared during your interview.

3. Practice Your Interview Skills

The best way to prepare for an interview is to practice. You can practice with a friend or family member, or you can use a mock interview website or app. Practicing will help you to become more comfortable with the interview process and to improve your communication skills.

4. Dress Professionally and Arrive on Time

It is important to dress professionally for your interview. This shows the interviewer that you are serious about the position and that you respect the company. You should also arrive on time for your interview. Punctuality shows the interviewer that you are reliable and organized.

5. Be Yourself and Be Confident

The most important thing is to be yourself and to be confident. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident in your abilities and your qualifications, and let the interviewer see your personality.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Roving Weight Gauger role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.