Are you gearing up for a career in Roving Winder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Roving Winder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

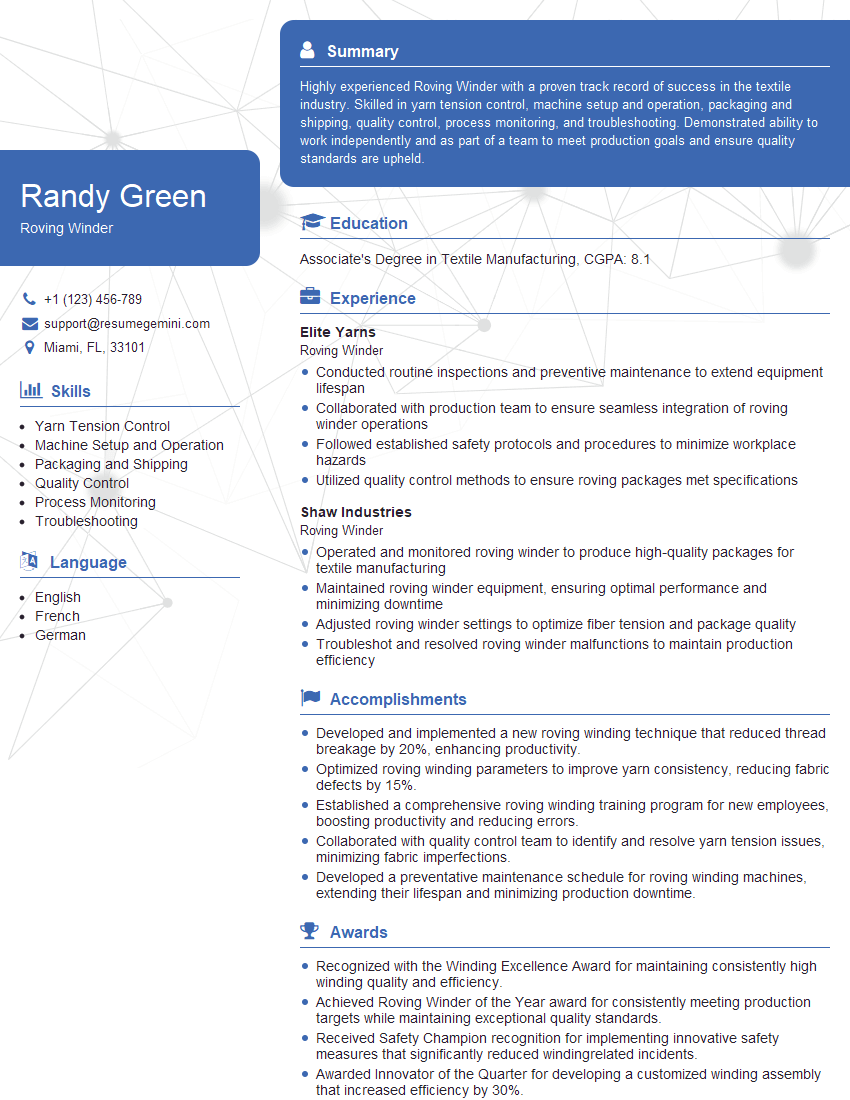

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Roving Winder

1. What are the different types of roving winders?

There are two main types of roving winders:

- Continuous roving winders: These winders produce a continuous strand of roving by winding the fibers onto a bobbin.

- Intermittent roving winders: These winders produce a series of short, individual rovings by winding the fibers onto a series of bobbins.

2. What are the key components of a roving winder?

Drive system

- Motor

- Gearbox

- Couplings

Roving creel

- Roving bobbins

- Roving guides

- Tensioners

Winding head

- Bobbin

- Yarn guide

- Traverse mechanism

Control system

- PLC

- HMI

- Sensors

3. How does a roving winder work?

A roving winder works by winding the fibers from the roving bobbins onto a bobbin. The fibers are drawn from the bobbins and passed through a series of tensioners and guides. The fibers are then wound onto the bobbin by the winding head. The traverse mechanism ensures that the fibers are evenly distributed across the bobbin.

4. What are the different factors that affect the quality of the roving?

- Fiber quality

- Roving tension

- Winding speed

- Bobbin size

- Environmental conditions

5. How do you troubleshoot a roving winder?

- Check the roving creel for any problems.

- Check the winding head for any problems.

- Check the control system for any problems.

- Check the environment for any problems that could affect the winder.

6. How do you maintain a roving winder?

- Clean the winder regularly.

- Inspect the winder for any problems.

- Lubricate the winder according to the manufacturer’s instructions.

- Calibrate the winder according to the manufacturer’s instructions.

7. What are the safety precautions that you must take when operating a roving winder?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Do not operate the winder if you are not properly trained.

- Do not operate the winder if it is not in good working condition.

- Do not touch the moving parts of the winder.

- Do not leave the winder unattended while it is in operation.

8. What is the difference between a roving winder and a yarn winder?

- Roving winders wind fibers into a roving, which is a loose, untwisted strand.

- Yarn winders wind roving into yarn, which is a twisted, strong strand.

9. What are the different types of roving winder creels?

- Rotating creels: These creels rotate the roving bobbins to ensure that the fibers are evenly distributed across the bobbin.

- Stationary creels: These creels do not rotate the roving bobbins. Instead, the fibers are drawn from the bobbins by the winding head.

10. What are the different types of roving winder winding heads?

- Drum winding heads: These winding heads use a drum to wind the fibers onto the bobbin.

- Disc winding heads: These winding heads use a disc to wind the fibers onto the bobbin.

- Belt winding heads: These winding heads use a belt to wind the fibers onto the bobbin.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Roving Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Roving Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Roving Winders play a crucial role in the textile industry, operating and maintaining machines that produce roving, a continuous strand of fibers used in the manufacturing of yarn and thread.

1. Machine Operation and Maintenance

• Operate roving machines to produce roving of specified quality and quantity.

• Conduct regular maintenance tasks on roving machines, ensuring optimal performance.

• Identify and troubleshoot machine malfunctions, implementing corrective measures.

• Adjust machine settings to optimize roving production and quality.

2. Material Handling

• Handle and load raw materials, such as slivers and roving, onto machines.

• Unload finished roving from machines, ensuring proper storage and handling.

• Maintain a clean and organized work area, adhering to safety regulations.

3. Quality Control

• Inspect roving for defects and ensure it meets established quality standards.

• Monitor machine performance and adjust settings as necessary to maintain consistent roving quality.

• Collaborate with quality control personnel to investigate and resolve any quality issues.

4. Production Support

• Assist other team members in production-related tasks, such as doffing and creeling.

• Maintain accurate production records and report any discrepancies or issues to supervisors.

• Follow safety protocols and maintain a safe work environment.

Interview Tips

To help you ace your interview for a Roving Winder position, here are some key tips and preparation hacks:

1. Research the Company and Position

• Thoroughly research the company’s website, industry publications, and social media pages.

• Understand the company’s mission, values, and products/services.

• Review the job description and identify the key skills and requirements.

2. Practice Your Answers

• Prepare for common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

• Practice your answers to technical questions related to roving machine operation and maintenance.

• Be prepared to discuss your experience in quality control and production support.

3. Highlight Your Skills and Experience

• Emphasize your hands-on experience in operating and maintaining roving machines.

• Showcase your ability to identify and troubleshoot machine malfunctions.

• Highlight your attention to detail and commitment to maintaining high-quality standards.

4. Demonstrate Your Teamwork and Problem-Solving Abilities

• Discuss your experience working in a team environment and supporting other team members.

• Share examples of how you have resolved production issues or improved efficiency.

• Emphasize your ability to think critically and find solutions independently.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Roving Winder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!