Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Rubber Block Layer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Rubber Block Layer so you can tailor your answers to impress potential employers.

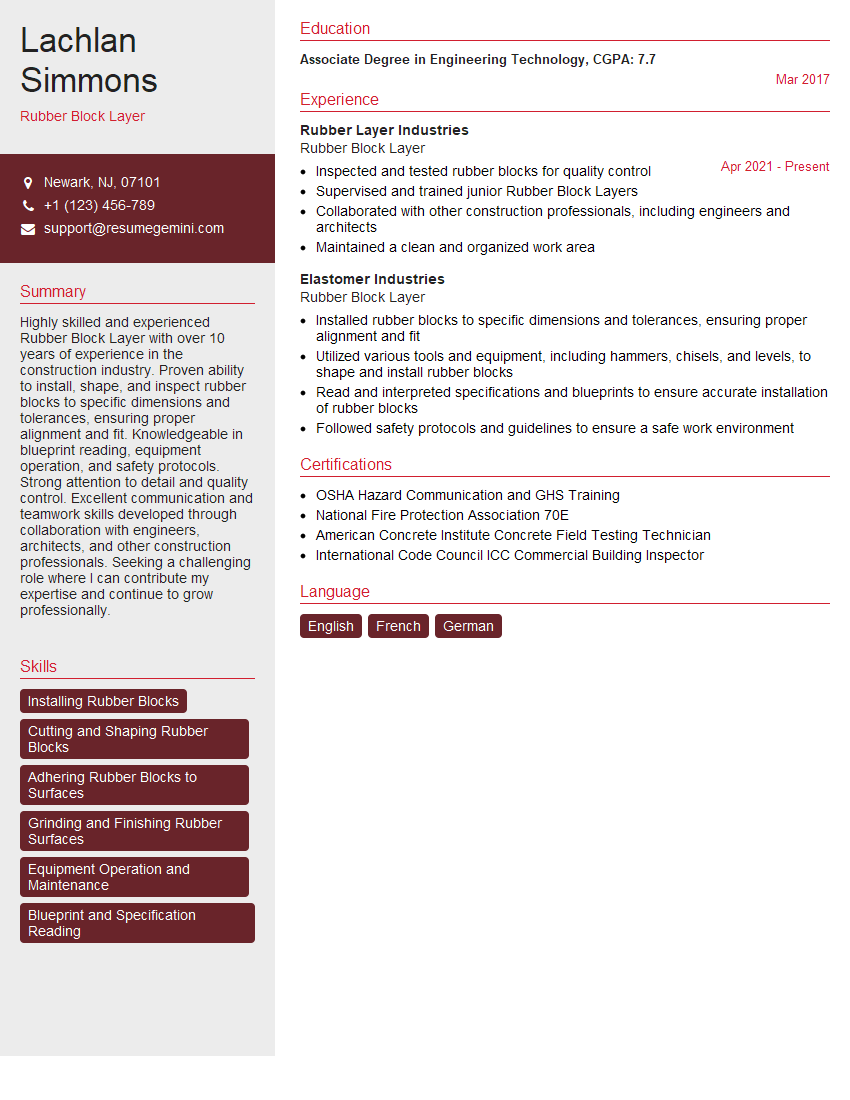

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Block Layer

1. Please outline the key steps involved in installing rubber block on a concrete surface?

- Prepare the concrete surface by cleaning and leveling it.

- Apply a primer to the concrete surface to enhance adhesion.

- Cut the rubber blocks to the desired size and shape.

- Apply adhesive to the back of the rubber blocks.

- Place the rubber blocks on the concrete surface and press firmly.

- Allow the adhesive to cure according to the manufacturer’s instructions.

2. What are the different types of adhesives used for installing rubber blocks?

Water-based adhesives

- Easy to apply and clean up.

- Less toxic than solvent-based adhesives.

- Not as strong as solvent-based adhesives.

Solvent-based adhesives

- Stronger than water-based adhesives.

- More difficult to apply and clean up.

- More toxic than water-based adhesives.

3. What are some common problems that can occur during rubber block installation, and how would you address them?

- Improper surface preparation: Can lead to poor adhesion. Address by cleaning and leveling the surface properly.

- Incorrect adhesive selection: Can lead to weak bonding. Address by selecting the appropriate adhesive for the specific application.

- Inadequate adhesive application: Can lead to delamination. Address by applying the adhesive evenly and according to the manufacturer’s instructions.

- Insufficient curing time: Can lead to premature failure. Address by allowing the adhesive to cure completely before subjecting the surface to traffic or use.

4. How do you ensure that the rubber blocks are installed level and aligned?

- Use a level to check the surface before installing the blocks.

- Use a chalk line to mark the desired alignment.

- Install the blocks carefully, pressing firmly to ensure they are flush with the surface.

- Check the level and alignment again after the blocks are installed.

5. What safety measures should be taken when working with rubber blocks and adhesives?

- Wear gloves, eye protection, and a respirator to avoid contact with adhesives and airborne particles.

- Ventilate the work area to prevent exposure to harmful fumes.

- Do not smoke or eat while working with adhesives.

- Clean up spills immediately to prevent slips and falls.

6. How do you determine the best layout for rubber blocks on a given surface?

- Consider the purpose of the surface and the desired traffic patterns.

- Measure the surface and calculate the number of blocks needed.

- Sketch out a layout plan that minimizes waste and optimizes the coverage.

- Make adjustments to the layout as needed to accommodate any obstacles or irregular surfaces.

7. What are the advantages and disadvantages of using rubber blocks as a flooring material?

Advantages

- Durable and long-lasting

- Slip-resistant

- Comfortable to walk on

- Easy to clean and maintain

Disadvantages

- Can be expensive to purchase and install

- Can be difficult to repair if damaged

- Not suitable for all applications

8. How do you estimate the cost of a rubber block installation project?

- Calculate the square footage of the surface to be covered.

- Determine the cost per square foot of the rubber blocks.

- Factor in the cost of adhesive and other materials.

- Estimate the labor cost based on the complexity of the project.

- Add a contingency for unexpected expenses.

9. What are some innovative applications of rubber blocks?

- Playground surfacing

- Sports fields

- Industrial flooring

- Noise reduction barriers

- Custom art installations

10. How do you stay up-to-date on the latest trends and technologies in rubber block installation?

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Network with other professionals in the field.

- Explore new products and technologies from manufacturers.

- Seek opportunities for continuing education.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Block Layer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Block Layer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rubber Block Layers, also known as Linoleum Layers, are responsible for installing and repairing rubber flooring and other types of floor coverings in commercial and residential buildings. Their primary duties include:

1. Installation and Repair of Rubber Flooring

- Measuring, cutting, and installing rubber flooring according to specifications.

- Preparing subfloors by leveling, smoothing, and applying adhesives or primers.

- Repairing or replacing damaged rubber flooring, including patching, filling, and sealing.

- Inspecting finished installations to ensure compliance with building codes and industry standards.

2. Maintenance and Upkeep

- Cleaning and maintaining rubber flooring to preserve its appearance and performance.

- Applying protective coatings or sealants to extend the life of the flooring.

- Monitoring flooring for signs of wear, damage, or deterioration.

3. Safety and Compliance

- Adhering to all safety regulations and industry best practices.

- Wearing appropriate personal protective equipment (PPE) while handling materials and operating equipment.

4. Communication and Coordination

- Communicating with clients, architects, and contractors to discuss project requirements.

- Coordinating with other tradespeople, such as electricians and plumbers, to ensure smooth project execution.

Interview Tips

To ace an interview for a Rubber Block Layer position, candidates should prepare by understanding the key responsibilities of the role and practicing their responses to common interview questions. Here are some tips and hacks:

1. Research the Company and Position

- Learn about the company’s history, services, and clientele.

- Review the job description thoroughly to identify the specific qualifications and responsibilities required.

- Research industry trends and advancements related to rubber flooring installation and maintenance.

2. Highlight Relevant Skills and Experience

- Emphasize your experience in installing and repairing rubber flooring, including the types of materials and techniques you have worked with.

- Showcase your knowledge of safety regulations and industry best practices.

- Highlight any additional skills or certifications that enhance your candidacy, such as waterproofing, floor leveling, or project management.

3. Prepare for Technical Questions

4. Demonstrate Enthusiasm and Professionalism

- Convey your passion for flooring and your commitment to providing high-quality installations.

- Dress professionally and arrive on time for your interview.

- Be polite and respectful to everyone you encounter during the interview process.

5. Ask Thoughtful Questions

- Prepare questions to ask the interviewer, demonstrating your interest in the position and the company.

- Inquire about the company’s growth plans, industry trends, or any specific projects related to rubber flooring installation.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rubber Block Layer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.