Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rubber Chemist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

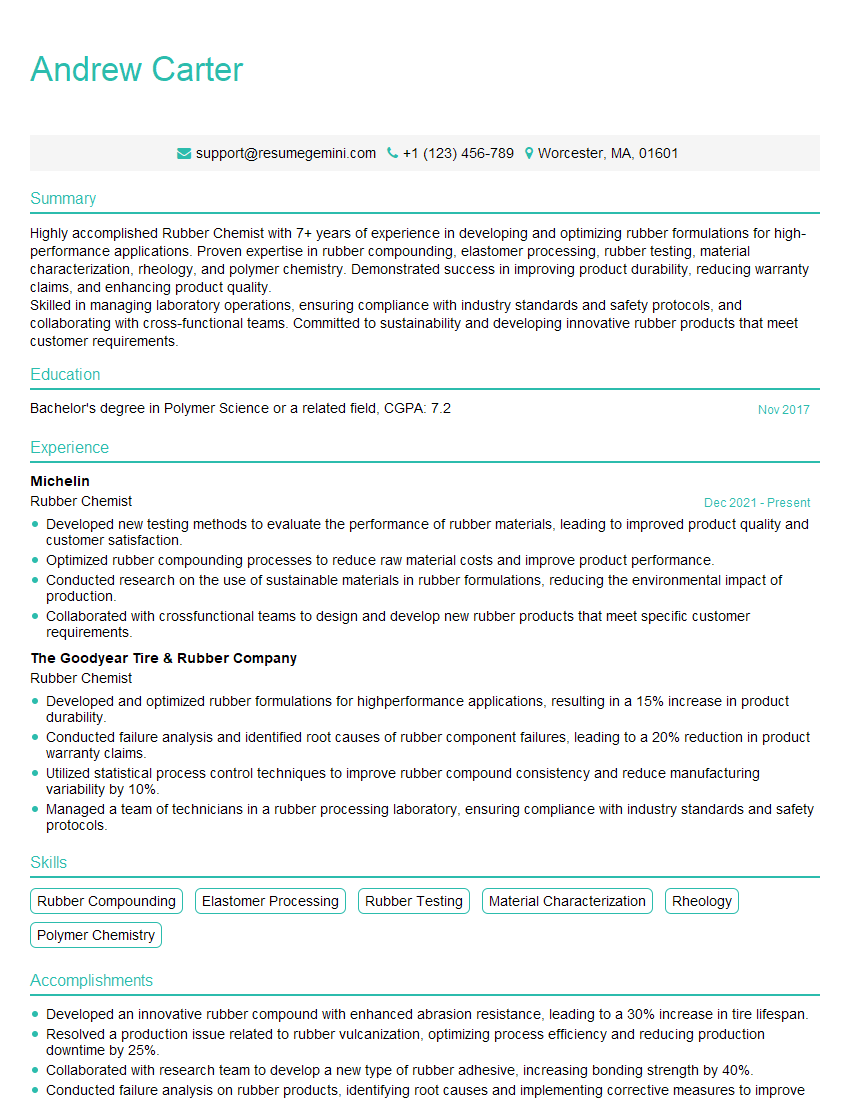

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Chemist

1. What are the key steps involved in the rubber compounding process?

In the rubber compounding process, raw rubber is mixed with various ingredients to achieve the desired properties. Key steps involved are:

- Mixing: Raw rubber, fillers, and other ingredients are mixed to create a uniform compound.

- Milling: The mixed compound is further processed to break down the rubber particles and distribute fillers evenly.

- Shaping: The compound is shaped into sheets, rolls, or other forms depending on the intended application.

- Vulcanization: The shaped compound is heated in the presence of sulfur or other curing agents to form cross-links between rubber chains, leading to improved strength and durability.

- Finishing: After vulcanization, the rubber product undergoes final processes such as trimming, inspection, and packaging.

2. How do you determine the appropriate rubber formulation for a specific application?

Factors to Consider:

- Intended Use: The application’s requirements, such as strength, flexibility, and durability, determine the formulation.

- Material Properties: The desired properties of the rubber, such as tensile strength, elongation, and hardness, must be considered.

- Processing Conditions: Factors like mixing, molding, and curing methods impact the formulation choice.

- Environmental Factors: Exposure to elements like temperature, ozone, and chemicals must be accounted for.

- Cost and availability: The economic and practical aspects of ingredient selection are important.

Formulation Development:

- Literature Review: Research similar applications and existing formulations.

- Experimental Trials: Conduct small-scale experiments to test different formulations and evaluate outcomes.

- Statistical Analysis: Use statistical methods to analyze data and optimize the formulation.

- Iterative Process: Adjust and refine the formulation based on test results until the desired properties are achieved.

3. What are the different types of rubber additives and their functions?

- Fillers: Reinforce and strengthen rubber, e.g., carbon black, silica

- Plasticizers: Improve flexibility and processability, e.g., phthalates, waxes

- Antioxidants: Inhibit degradation caused by oxygen, ozone, and heat, e.g., butylated hydroxytoluene (BHT)

- Anti-degradants: Protect rubber from aging and environmental factors, e.g., UV absorbers, heat stabilizers

- Accelerators: Catalyze the vulcanization process, speeding up curing time, e.g., sulfur, amines

- Tackifiers: Promote adhesion between rubber surfaces or with other materials, e.g., resins

- Colorants: Provide specific color to rubber compounds, e.g., pigments, dyes

4. Explain the principles of rubber vulcanization and its impact on rubber properties.

- Chemical Reaction: Vulcanization involves cross-linking of rubber chains using sulfur or other curing agents.

- Formation of Sulfur Bridges: Sulfur atoms react with double bonds in rubber chains, forming covalent bonds that create cross-links.

- Increased Strength and Durability: Cross-linking creates a three-dimensional network, significantly improving tensile strength, tear resistance, and elasticity.

- Reduced Plasticity: Vulcanization restricts the movement of rubber chains, reducing its plasticity and making it more rigid.

- Improved Heat Resistance: Cross-linked rubber chains resist thermal degradation and maintain their properties at higher temperatures.

5. Discuss the role of testing and quality control in the rubber industry.

- Material Characterization: Testing raw materials to ensure they meet specifications for compounding.

- Process Monitoring: Evaluating compound properties during mixing, shaping, and vulcanization to optimize production.

- Product Performance Assessment: Testing finished rubber products to verify their adherence to quality standards and customer requirements.

- Failure Analysis: Investigating product failures to identify root causes and implement corrective actions.

- Quality Assurance: Establishing and maintaining quality systems to ensure consistent production of high-quality rubber products.

6. Describe the different methods for rubber reinforcement and their effects on rubber properties.

- Carbon Black Reinforcement: Adds strength and abrasion resistance by forming a network of carbon particles within the rubber matrix.

- Silica Reinforcement: Enhances tear strength and improves traction by forming strong bonds with rubber.

- Polymer Reinforcement: Incorporating high-performance polymers, such as Kevlar or nylon, to increase tensile strength and modulus.

- Metal Oxide Reinforcement: Using metal oxides, such as zinc oxide or magnesium oxide, to improve stiffness and adhesion.

7. Explain the concept of rubber elasticity and its importance in rubber applications.

- Definition: Rubber’s ability to undergo large deformations and return to its original shape when the stress is removed.

- Molecular Structure: Elasticity arises from the long, flexible polymer chains in rubber.

- Mechanism of Deformation: When stretched, rubber chains unwind and align, storing elastic energy.

- Importance in Applications: Elasticity enables rubber products to absorb energy, withstand impact, and provide cushioning.

8. Describe the different types of rubber processing equipment and their uses.

- Mixing Mills: Mix and masticate raw rubber and ingredients to create a uniform compound.

- Extruders: Force rubber compound through a die to create continuous profiles, such as tubes or hoses.

- Calenders: Roll and shape rubber compound into sheets or films with controlled thickness.

- Vulcanizers: Heat and pressure-cure rubber compounds to form cross-links and achieve desired properties.

- Molding Presses: Form rubber compounds into specific shapes using molds and pressure.

9. Discuss the environmental considerations in the rubber industry and sustainable practices.

- Raw Material Sourcing: Sustainable sourcing of natural rubber and synthetic materials.

- Waste Management: Minimization, recycling, and proper disposal of rubber waste.

- Energy Efficiency: Optimizing energy consumption in manufacturing processes.

- Emissions Control: Reducing emissions of volatile organic compounds (VOCs) and other pollutants.

- Biodegradable Rubbers: Development and use of environmentally friendly, biodegradable rubber materials.

10. How do you stay updated with the latest advancements in rubber chemistry and technology?

- Industry Journals and Publications: Reading specialized publications, such as “Rubber Chemistry and Technology.”

- Conferences and Webinars: Attending industry events to learn about new developments and network with experts.

- Online Resources: Utilizing websites and databases dedicated to rubber science and technology.

- Collaboration with Universities and Research Institutions: Engaging in joint projects or attending seminars to access cutting-edge research.

- Continuing Education Courses: Taking courses or workshops to enhance knowledge and skills in specific areas.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Chemist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Chemist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rubber Chemists are responsible for developing, testing, and improving rubber products. They work in laboratories to create new rubber compounds and evaluate their performance.

1. Research and Development

Rubber Chemists conduct research to develop new rubber compounds and improve the properties of existing compounds. They may also work on developing new applications for rubber.

- Conduct research to develop new rubber compounds

- Improve the properties of existing rubber compounds

- Develop new applications for rubber

2. Testing and Evaluation

Rubber Chemists test rubber compounds to evaluate their performance. They may also test finished rubber products to ensure that they meet specifications.

- Test rubber compounds to evaluate their performance

- Test finished rubber products to ensure that they meet specifications

3. Production Support

Rubber Chemists may provide technical support to production staff. They may also help to troubleshoot problems with rubber products.

- Provide technical support to production staff

- Help to troubleshoot problems with rubber products

4. Quality Control

Rubber Chemists may be responsible for developing and implementing quality control procedures. They may also inspect rubber products to ensure that they meet quality standards.

- Develop and implement quality control procedures

- Inspect rubber products to ensure that they meet quality standards

Interview Tips

Preparing for a job interview can be nerve-wracking, but it doesn’t have to be. With the right preparation, you can enter the interview with confidence and increase your chances of success.

1. Do your research

The first step in preparing for an interview is to do your research. This includes learning about the company, the position you are applying for, and the industry. You should also research the interviewer, if possible.

- Visit the company’s website to learn about their history, mission, and values.

- Read the job description carefully to understand the responsibilities of the position.

- Research the industry to learn about the latest trends and challenges.

- If possible, try to find out who will be interviewing you and research their background.

2. Practice your answers

Once you have done your research, it is time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Write down a list of common interview questions and practice your answers.

- Ask a friend or family member to mock interview you.

- Record yourself answering interview questions and then watch it back to see how you can improve.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the company culture.

- Choose clothes that are clean, pressed, and fit you well.

- Consider the company culture when choosing your outfit. For example, if you are interviewing for a job at a tech startup, you may want to dress more casually than if you were interviewing for a job at a law firm.

4. Be on time

Punctuality shows that you are respectful of the interviewer’s time. Aim to arrive at the interview location 10-15 minutes early.

- Plan your route ahead of time and give yourself extra time for traffic or unexpected delays.

- If you are running late, call or email the interviewer to let them know.

Next Step:

Now that you’re armed with the knowledge of Rubber Chemist interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rubber Chemist positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini