Are you gearing up for an interview for a Rubber Curer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rubber Curer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

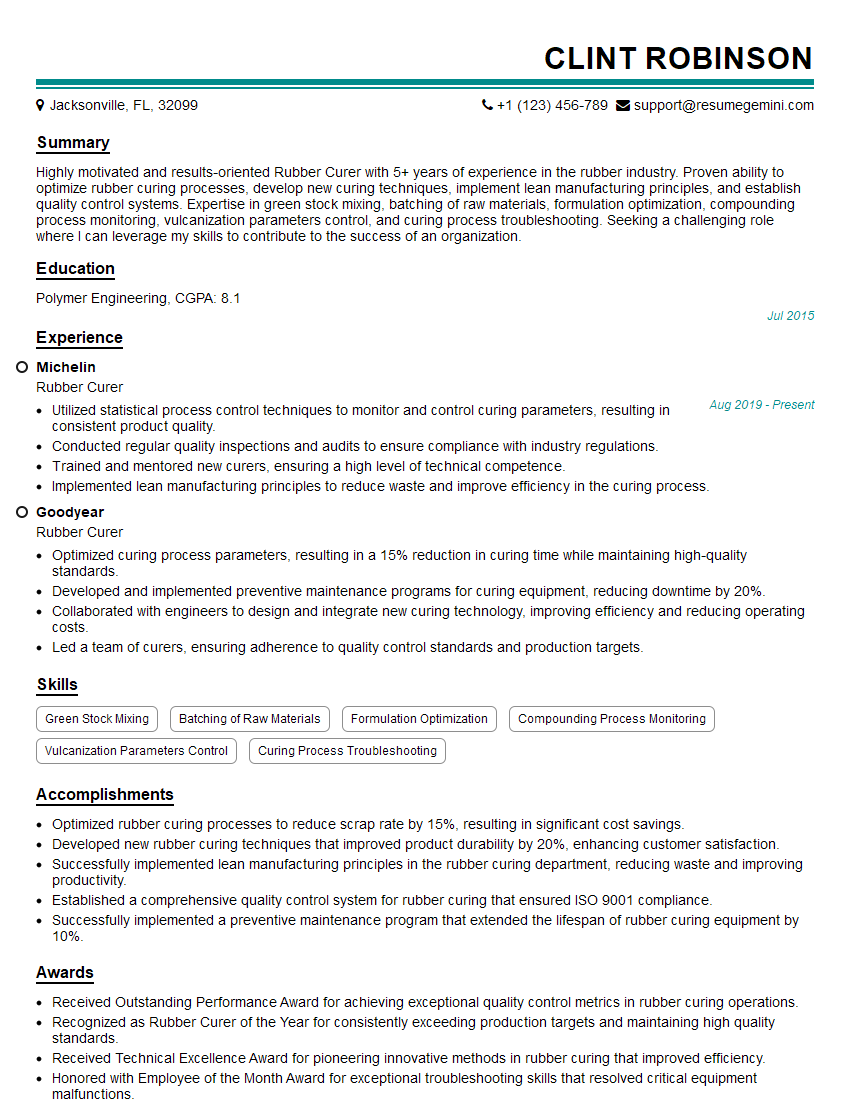

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Curer

1. Describe the curing process of rubber and explain the different stages involved?

- Induction period: During this stage, the rubber compound absorbs heat and begins to soften, but there is no significant change in its shape.

- Plasticity period: The rubber compound becomes more pliable and can be deformed without breaking. The cross-linking process begins during this stage.

- Vulcanization period: The cross-linking process continues, and the rubber compound becomes more rigid and strong. The final properties of the rubber are determined by the degree of cross-linking.

- Overcure period: If the rubber compound is overheated or overcured, it will become brittle and weak.

2. What are the different types of rubber curing systems?

Hot curing

- Sulfur curing: This is the most common type of rubber curing system. It involves heating the rubber compound in the presence of sulfur, which forms cross-links between the rubber molecules.

- Peroxide curing: This system uses organic peroxides to cross-link the rubber molecules. It is often used for rubber compounds that require high performance properties.

Cold curing

- Room temperature vulcanization (RTV): This system uses a catalyst to cross-link the rubber molecules at room temperature. It is often used for rubber compounds that require low-temperature flexibility.

- Microwave curing: This system uses microwaves to heat the rubber compound and cross-link the rubber molecules. It is often used for rubber compounds that require fast curing times.

3. What are the factors that affect the curing process of rubber?

- Temperature: The curing temperature has a significant effect on the rate and degree of cross-linking. Higher temperatures generally result in faster curing times and higher degrees of cross-linking.

- Time: The curing time affects the degree of cross-linking. Longer curing times generally result in higher degrees of cross-linking.

- Curing agents: The type and concentration of curing agents used affect the rate and degree of cross-linking. Different curing agents produce different types of cross-links.

- Rubber compound composition: The composition of the rubber compound, including the type of rubber, fillers, and additives, can affect the curing process.

4. What are the different methods used to test the quality of cured rubber?

- Tensile strength: This test measures the force required to break a rubber sample. It is a measure of the rubber’s strength.

- Elongation at break: This test measures the amount that a rubber sample can be stretched before it breaks. It is a measure of the rubber’s flexibility.

- Hardness: This test measures the resistance of a rubber sample to indentation. It is a measure of the rubber’s stiffness.

- Resilience: This test measures the ability of a rubber sample to recover its original shape after being deformed. It is a measure of the rubber’s elasticity.

5. What are the common defects that can occur during the curing process of rubber?

- Undercure: This occurs when the rubber compound is not cured long enough or at a high enough temperature. The rubber will be soft and weak.

- Overcure: This occurs when the rubber compound is cured too long or at too high a temperature. The rubber will be hard and brittle.

- Scorching: This occurs when the rubber compound is exposed to excessive heat for a short period of time. The rubber will be discolored and weak.

- Blisters: These are air pockets that can form in the rubber compound during the curing process. They can weaken the rubber and make it more susceptible to failure.

6. What are the safety precautions that should be taken when working with rubber curing agents?

- Wear appropriate protective gear, including gloves, goggles, and a respirator.

- Work in a well-ventilated area.

- Avoid contact with skin and eyes.

- Wash hands thoroughly after handling rubber curing agents.

- Store rubber curing agents in a safe and secure location.

7. What are the latest trends in rubber curing technology?

- Use of microwave and radio frequency curing: These technologies offer faster curing times and more uniform heating.

- Development of new curing agents: These agents are designed to improve the performance of rubber compounds and reduce the risk of defects.

- Use of computer modeling to optimize the curing process: This technology can help to reduce curing times and improve the quality of cured rubber.

8. What are the most important qualities of a successful rubber curer?

- Technical knowledge of rubber curing processes and equipment.

- Ability to troubleshoot and solve problems.

- Attention to detail and quality control.

- Strong communication and interpersonal skills.

- Ability to work independently and as part of a team.

9. What are your career goals as a rubber curer?

- To gain experience in all aspects of rubber curing.

- To contribute to the development and implementation of new curing technologies.

- To advance my career to a leadership position in the rubber industry.

10. What is your understanding of the role of a rubber curer in the rubber industry?

- To ensure that rubber products meet the required specifications and quality standards.

- To optimize the curing process to achieve the desired properties of the rubber products.

- To troubleshoot and solve problems that may arise during the curing process.

- To work with other members of the rubber production team to ensure that the rubber products are produced efficiently and safely.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Curer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Curer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rubber Curers are the backbone of the rubber industry, playing a crucial role in transforming raw rubber into useful products. Their primary responsibilities involve:

1. Curing Process Oversight

The most critical task for a Rubber Curer is to oversee the curing process, which involves heating and mixing rubber with chemicals to enhance its properties. They monitor temperature, pressure, and time to ensure the rubber cures correctly, resulting in products with optimal strength, elasticity, and durability.

2. Equipment Maintenance and Operation

Rubber Curers are also responsible for operating and maintaining the equipment used in the curing process, including mixers, presses, and ovens. They ensure that the equipment is in good working order and calibrate it regularly to maintain accuracy and efficiency.

3. Quality Control and Testing

Quality control is paramount for Rubber Curers. They conduct tests on cured rubber to assess its properties and ensure it meets industry standards and customer specifications. This involves performing physical tests (e.g., tensile strength, elongation, hardness) and chemical analysis to verify the rubber’s composition and performance.

4. Production Planning and Scheduling

Rubber Curers work closely with production teams to plan and schedule curing processes efficiently. They coordinate with suppliers to ensure timely delivery of raw materials and manage inventory to avoid shortages or overstocking.

5. Safety and Environmental Compliance

Safety and environmental compliance are top priorities in the rubber industry. Rubber Curers are responsible for adhering to safety regulations, wearing appropriate protective gear, and following environmental protocols to minimize hazards and protect the environment.

Interview Tips

To ace an interview for a Rubber Curer position, candidates should follow these tips:

1. Research the Company and Industry

Thoroughly research the company and the rubber industry before the interview. Understand the company’s history, products, and market position. Also, familiarize yourself with industry trends and advancements to demonstrate your knowledge and interest.

2. Highlight Relevant Experience

Emphasize your experience in rubber curing or related fields. Describe your responsibilities and accomplishments in detail, quantifying results whenever possible. Use specific examples to illustrate your skills in overseeing the curing process, equipment operation, and quality control.

3. Demonstrate Knowledge of Equipment

Show that you are familiar with the equipment used in rubber curing. Explain your experience in operating and maintaining mixers, presses, and ovens. Discuss your understanding of temperature, pressure, and time controls, and how these factors impact the curing process.

4. Showcase Quality Control Expertise

Interviewers will be interested in your quality control expertise. Describe your experience in conducting physical and chemical tests on rubber. Explain how you interpret results and ensure that products meet specifications. Highlight your knowledge of industry standards and testing methodologies.

5. Prepare for Behavioral Questions

Be prepared to answer behavioral questions that assess your problem-solving skills, teamwork abilities, and attention to safety. Provide specific examples from your work experience that demonstrate your ability to handle challenges, collaborate with others, and prioritize safety.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rubber Curer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.