Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rubber Cutter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

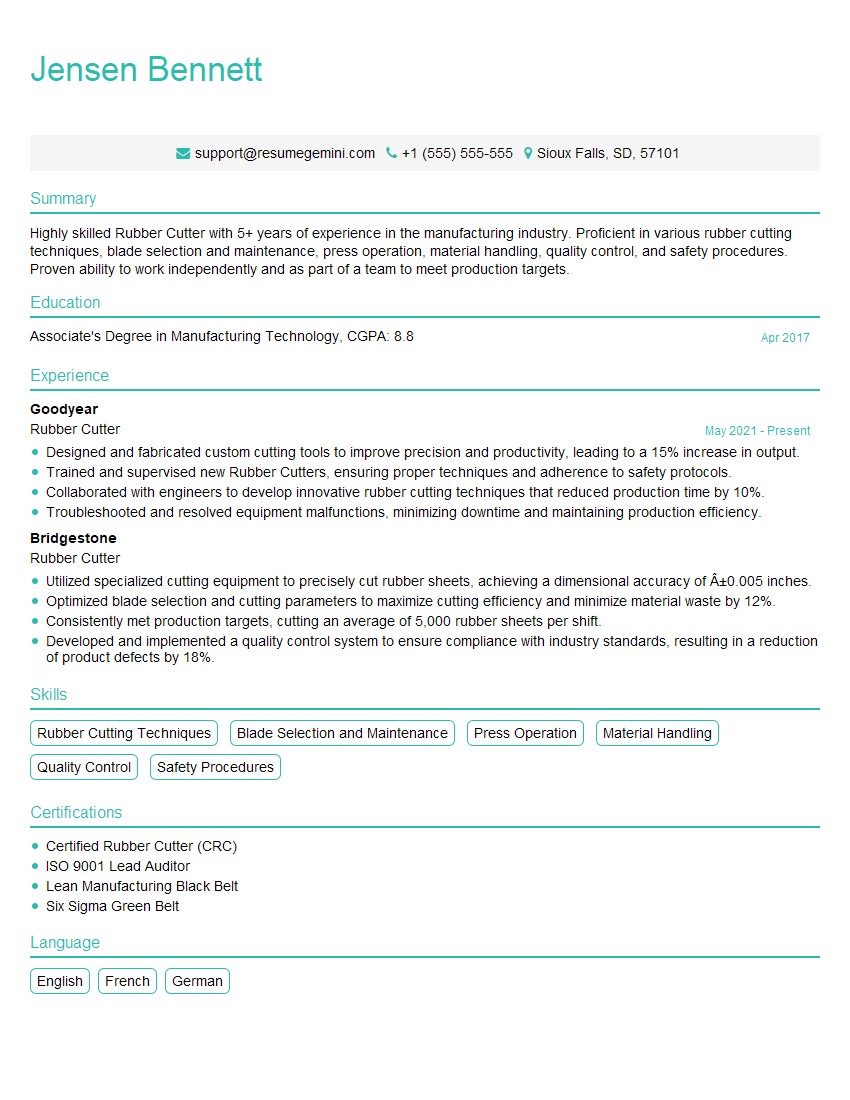

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Cutter

1. What are the different types of rubber cutters and which one would you use for a specific task?

There are various types of rubber cutters, each designed for specific tasks. Here are a few examples:

- Guillotine cutter: Ideal for straight and precise cuts on thick rubber sheets

- Band knife cutter: Used for intricate and curved cuts on various rubber thicknesses

- Die cutter: Employs a sharp die to cut specific shapes out of rubber

- Waterjet cutter: Utilizes a high-pressure water stream to cut rubber with minimal heat generation

- Laser cutter: Employs a focused laser beam to cut rubber with high precision

Regarding the specific task, I would consider factors such as the rubber thickness, desired cut shape, and required precision when selecting the most suitable rubber cutter.

2. How do you ensure the accuracy and precision of your cuts?

Measuring and Marking

- Use precision measuring tools to accurately mark the desired cut lines

- Utilize templates or guides for repetitive cuts

Machine Setup

- Ensure the rubber cutter is properly calibrated and aligned

- Adjust blade sharpness and cutting pressure to suit the rubber thickness and desired cut quality

Cutting Technique

- Maintain a steady hand and apply even pressure while cutting

- Use a sharp blade to minimize tearing and ensure clean cuts

Quality Control

- Regularly inspect cut pieces to verify accuracy and precision

- Implement statistical process control techniques to monitor and improve cutting quality

3. What are the safety precautions you take when operating rubber cutters?

- Wear appropriate safety gear, including gloves, safety glasses, and a mask

- Ensure the work area is well-ventilated to avoid inhaling rubber dust

- Keep hands away from the cutting blade and moving parts

- Never attempt to operate the machine with a dull or damaged blade

- Follow established safety protocols and procedures

- Receive proper training and authorization before operating rubber cutters

4. How do you troubleshoot common problems encountered while rubber cutting?

I would approach troubleshooting common rubber cutting problems systematically:

- Inaccurate cuts: Check measuring tools, machine calibration, blade sharpness, and cutting technique

- Tearing or ragged edges: Assess blade sharpness, cutting pressure, and rubber material characteristics

- Machine malfunction: Inspect electrical connections, mechanical components, and hydraulic systems

- Safety issues: Ensure proper safety precautions are in place, including ventilation and protective gear

- Poor cut quality: Analyze rubber material, cutting parameters, and operator skills

5. What maintenance procedures do you follow to keep rubber cutters in optimal condition?

- Regular cleaning: Remove rubber debris and dust from the machine to prevent jamming and wear

- Blade replacement: Replace dull or damaged blades promptly to maintain cutting accuracy

- Lubrication: Lubricate moving parts as per manufacturer’s instructions to minimize friction and extend machine life

- Calibration and adjustments: Periodically calibrate and adjust the machine to ensure precision and accuracy

- Preventive maintenance: Conduct scheduled inspections and repairs to identify potential issues and prevent breakdowns

6. How do you handle and store rubber materials to maintain their integrity and prevent damage?

- Storage conditions: Store rubber in a cool, dry place away from direct sunlight to prevent degradation

- Handling techniques: Use proper lifting techniques to avoid stretching or tearing the rubber

- Protection from contaminants: Keep rubber away from dust, dirt, and chemicals to prevent contamination

- Inventory management: Implement a first-in, first-out (FIFO) system to ensure older materials are used first

- Proper stacking: Stack rubber sheets or rolls carefully to avoid damage and maintain their shape

7. How do you interpret technical drawings and specifications to accurately cut rubber components?

Interpreting technical drawings and specifications accurately is crucial for precise rubber cutting:

- Understanding symbols and conventions: Familiarize myself with industry-standard symbols and conventions used in technical drawings

- Measuring and scaling: Accurately measure and scale the drawings to determine the desired cut dimensions

- Identifying tolerances and allowances: Pay attention to specified tolerances and allowances to ensure parts meet design requirements

- Considering material properties: Take into account the properties of the rubber material being cut, such as its thickness and flexibility

- Communicating with engineers: If necessary, clarify any ambiguities or uncertainties with the engineers responsible for the drawings

8. Can you describe your experience in working with different rubber compounds and how you adjust your cutting techniques accordingly?

My experience with diverse rubber compounds has taught me to adapt my cutting techniques to suit their specific properties:

- Natural rubber: Requires sharp blades and precise cuts to prevent tearing

- Synthetic rubber: May require higher cutting pressure and specialized blades to achieve clean cuts

- EPDM rubber: Known for its resistance to heat and ozone, necessitating appropriate blade selection

- Silicone rubber: Exhibits high flexibility, demanding careful handling and blade adjustment

- Nitrile rubber: Possesses excellent oil resistance, requiring specific blade materials to avoid premature wear

By understanding the unique characteristics of each rubber compound, I can optimize my cutting techniques to deliver high-quality results.

9. How do you measure and ensure the quality of your finished rubber cuts?

- Dimensional accuracy: Use precision measuring tools, such as calipers and micrometers, to verify the dimensions of the cut pieces

- Visual inspection: Examine the cut edges for any irregularities, tears, or raggedness

- Surface finish: Check the surface of the cuts for smoothness and absence of burrs or debris

- Dimensional stability: Test the cut pieces for dimensional stability under varying conditions, such as temperature and humidity

- Compliance with specifications: Ensure that the cut pieces meet the specified tolerances and quality standards

10. Can you explain the principles of lean manufacturing and how you apply them in your work as a rubber cutter?

- Eliminating waste: Identify and eliminate non-value-added activities in the cutting process

- Continuous improvement: Regularly evaluate and improve cutting techniques and processes to enhance efficiency

- Just-in-time production: Plan and execute cutting operations to minimize inventory and reduce lead times

- Standardization: Establish standardized cutting procedures and work instructions to ensure consistency and quality

- Employee involvement: Engage employees in continuous improvement initiatives to foster ownership and innovation

By applying lean manufacturing principles, I aim to optimize cutting operations, reduce waste, and improve overall productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rubber Cutters play a crucial role in various industries, such as manufacturing, automotive, and construction. They are responsible for cutting and shaping rubber materials according to specified dimensions and requirements. Here are the key responsibilities of a Rubber Cutter:

1. Cutting and Shaping Rubber Materials

Rubber Cutters use specialized cutting tools and equipment to cut rubber sheets, strips, and other forms to precise dimensions. They may also use dies or templates to create specific shapes and sizes.

2. Inspecting and Quality Control

Rubber Cutters inspect the cut rubber materials for defects, such as nicks, cuts, or imperfections. They also ensure that the dimensions and specifications meet the required standards.

3. Maintaining Equipment

Rubber Cutters are responsible for maintaining the cutting equipment and tools. They perform regular cleaning, lubrication, and minor repairs to ensure optimal performance.

4. Following Safety Protocols

Rubber Cutters work in industrial environments with sharp tools and equipment. They must adhere to all safety regulations and procedures to prevent accidents.

Interview Tips

Preparing for an interview for a Rubber Cutter position requires research and practice. Here are some tips to ace the interview:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Rubber Cutter position. Understand their products, services, and industry standing. This knowledge demonstrates your interest and enthusiasm.

2. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses. Focus on highlighting your skills, experience, and why you are qualified for the role. Use the STAR method (Situation, Task, Action, Result) to provide specific examples.

3. Showcase Your Technical Skills

Rubber Cutters should be proficient in using cutting tools and equipment. During the interview, emphasize your experience with specific machines and processes. You could mention your ability to operate dies, shears, or presses.

4. Emphasize Safety and Quality Control

Interviewers will be interested in your commitment to safety and quality. Highlight your understanding of industry safety protocols and your attention to detail in inspecting rubber materials.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview, typically business casual or formal attire. Punctuality demonstrates respect for the interviewer’s time and conveys reliability.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rubber Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!