Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Rubber Goods Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Rubber Goods Inspector so you can tailor your answers to impress potential employers.

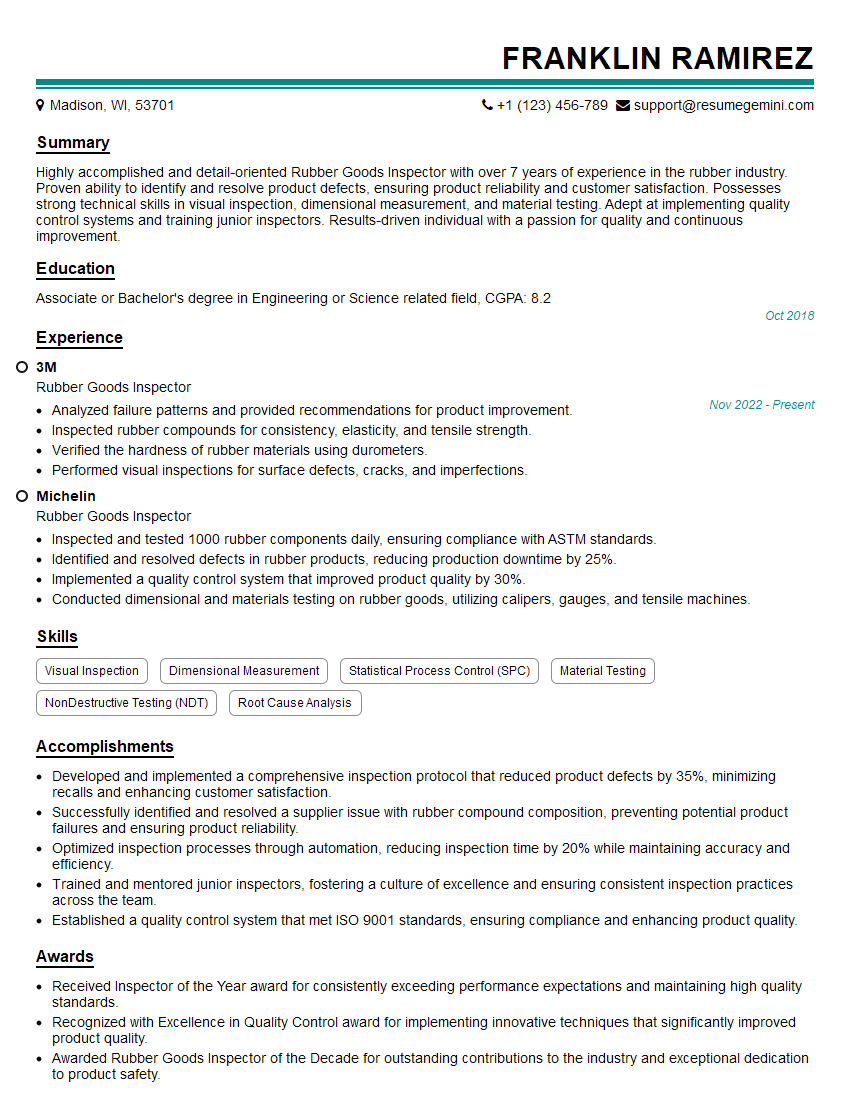

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Goods Inspector

1. What are the different types of rubber used in the manufacturing of rubber goods?

There are numerous types of rubber used in the production of rubber goods, categorized as natural or synthetic.

- Natural Rubber: Derived from the sap of rubber trees (Hevea brasiliensis), it offers excellent elasticity, resilience, and tensile strength.

- Synthetic Rubber: Created artificially, including various types such as Styrene-butadiene Rubber (SBR), Polybutadiene Rubber (BR), Nitrile Rubber (NBR), and Ethylene-Propylene-Diene Monomer Rubber (EPDM), each with unique properties tailored for specific applications.

2. Describe the various methods used for rubber component inspection.

Visual Inspection

- Scrutinizing components for defects such as cracks, tears, voids, discolorations, or surface imperfections.

Dimensional Inspection

- Verifying dimensions, such as length, width, thickness, and shape, using measuring tools like calipers, micrometers, or coordinate measuring machines (CMMs).

Hardness Testing

- Assessing the hardness of rubber materials using instruments such as durometers or Shore hardness testers.

Tensile Strength Testing

- Determining the tensile strength and elongation at break of rubber materials.

3. Explain the importance of quality control in rubber goods manufacturing.

Quality control is crucial in rubber goods manufacturing to ensure:

- Product Safety: Verifying that rubber goods meet safety standards and do not pose hazards to users.

- Product Performance: Ensuring that rubber goods perform as intended, meeting specified requirements for durability, elasticity, and resistance to environmental factors.

- Customer Satisfaction: Delivering high-quality products that meet customer expectations and enhance brand reputation.

- Cost Reduction: Identifying and preventing defects during the manufacturing process, reducing the likelihood of costly rework or product recalls.

4. What are the common defects found in rubber goods and their causes?

- Cracks: Improper curing, over-vulcanization, or exposure to harsh chemicals.

- Tears: Excessive force, sharp objects, or poor material quality.

- Voids: Air entrapment during molding, inadequate curing, or improper material mixing.

- Discolorations: Contamination, improper mixing of pigments, or exposure to sunlight.

- Dimensional Errors: Incorrect mold design, improper molding conditions, or shrinkage during curing.

5. Describe the process of rubber compounding and its significance.

Rubber compounding involves mixing raw rubber with various additives and chemicals to enhance its properties and performance.

- Fillers: Add strength, reduce cost, and modify physical properties.

- Vulcanizing Agents: Promote cross-linking and improve strength and durability.

- Antioxidants: Protect against degradation and extend product life.

- Accelerators: Speed up the vulcanization process.

- Pigments: Provide color and improve aesthetics.

6. Explain the different methods of rubber vulcanization.

- Sulfur Vulcanization: Traditional method using sulfur and accelerators to form cross-links.

- Peroxide Vulcanization: Uses organic peroxides as cross-linking agents, offering faster curing times.

- Microwave Vulcanization: Employs microwave energy to rapidly heat and cure rubber compounds.

7. Describe the role of rubber testing in ensuring product quality.

Rubber testing involves various methods to assess the properties of rubber materials and finished products, including:

- Tensile Testing: Evaluating tensile strength, elongation at break, and modulus of elasticity.

- Hardness Testing: Measuring the resistance of rubber to indentation.

- Tear Testing: Assessing the resistance of rubber to tearing.

- Aging Tests: Simulating environmental conditions to determine the effects of aging on rubber properties.

8. What are the essential characteristics of an effective rubber goods inspector?

- Technical Expertise: Thorough understanding of rubber materials, manufacturing processes, and inspection techniques.

- Attention to Detail: Ability to meticulously examine components for defects and non-conformities.

- Problem-Solving Skills: Capacity to identify and resolve discrepancies and suggest corrective actions.

- Communication Skills: Proficiency in reporting findings, documenting defects, and collaborating with production and quality teams.

- Quality-Oriented: Dedication to maintaining high standards and ensuring the production of quality rubber goods.

9. How do you stay updated with the latest advancements in rubber technology and inspection methods?

- Industry Conferences: Attending conferences and seminars to gain knowledge from experts and industry professionals.

- Trade Journals: Subscribing to trade publications and online resources for up-to-date information.

- Professional Development: Participating in training programs and workshops to enhance skills and stay abreast of new techniques.

- Networking: Connecting with other rubber goods inspectors, researchers, and manufacturers to exchange knowledge and experiences.

10. Describe a challenging inspection project you have encountered and how you successfully resolved it.

Provide a specific example of a complex inspection project and highlight your problem-solving abilities:

- Describe the challenge: Outline the specific situation and the difficulties encountered.

- Explain your approach: Describe the steps taken to investigate and analyze the issue.

- Highlight your findings: State the conclusions reached and the root cause of the problem.

- Discuss the solution: Explain how you identified and implemented corrective actions.

- Quantify results: If possible, provide measurable outcomes that demonstrate the success of your efforts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Goods Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Goods Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rubber Goods Inspectors play a vital role in ensuring the quality of rubber products, safeguarding consumer safety and brand reputation. Their primary responsibilities encompass:

1. Inspection

Conduct thorough visual and dimensional inspections of rubber products using specialized tools and gauges.

- Verify adherence to specifications, ensuring dimensional accuracy and surface finish.

- Identify any defects or non-conformities, such as cracks, tears, or contamination.

2. Testing

Perform quality control tests to assess rubber properties, such as hardness, tensile strength, and resistance to wear and tear.

- Operate testing equipment, record results, and analyze data to evaluate product performance.

- Ensure compliance with industry standards and customer specifications.

3. Reporting

Document inspection findings and test results in detailed reports.

- Provide clear and concise summaries of the product’s quality and adherence to standards.

- Communicate any non-conformities or areas for improvement to the production team.

4. Quality Control

Monitor and implement quality control procedures to maintain product consistency.

- Proactively identify and address potential quality issues.

- Collaborate with design and engineering teams to improve product quality.

Interview Tips

To excel in a Rubber Goods Inspector interview, consider the following tips:

1. Research

Thoroughly research the company, its products, and the specific role you are applying for.

- Understand the industry standards and regulations related to rubber goods manufacturing.

- Familiarize yourself with the company’s quality control processes and inspection techniques.

2. Highlight Skills

Emphasize your technical skills in inspection, testing, and quality control.

- Showcase your proficiency in using specialized tools and gauges.

- Highlight your expertise in performing various rubber testing procedures.

3. Present Experience

Provide concrete examples of your experience in rubber goods inspection.

- Describe specific projects where you successfully identified and resolved product defects.

- Explain how your contributions improved product quality and reduced manufacturing costs.

4. Enthusiasm and Motivation

Convey your passion for quality control and your commitment to delivering exceptional products.

- Express your eagerness to contribute to the company’s reputation for quality.

- Demonstrate your drive to continuously improve processes and enhance product performance.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rubber Goods Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.