Feeling lost in a sea of interview questions? Landed that dream interview for Rubber Goods Repairer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Rubber Goods Repairer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

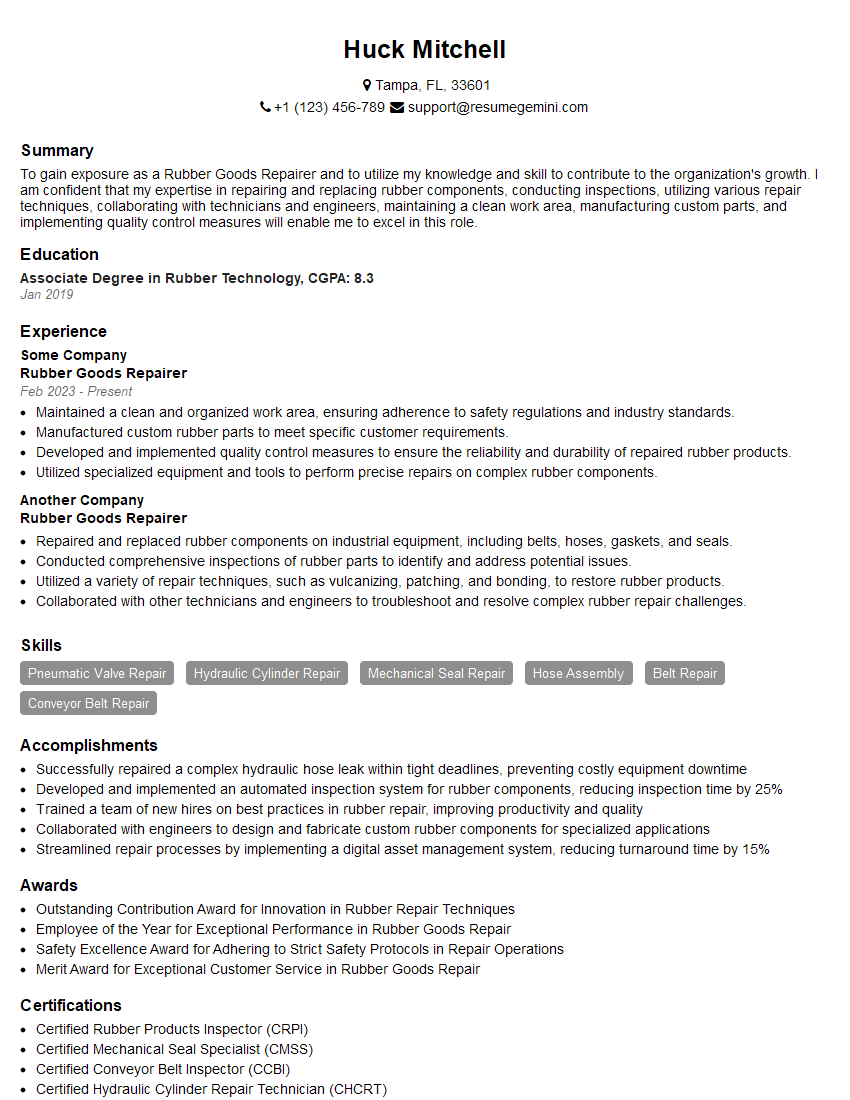

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Goods Repairer

1. What are the different types of rubber used in repairing rubber goods?

- Natural rubber: This is the most common type of rubber used in repairs, and it is known for its strength, durability, and flexibility.

- Synthetic rubber: This type of rubber is made from petroleum, and it is often used in place of natural rubber because it is less expensive and more resistant to oil and chemicals.

- Butyl rubber: This type of rubber is used in inner tubes and other applications where air retention is important.

- Nitrile rubber: This type of rubber is used in gaskets and seals because it is resistant to oil and chemicals.

2. What are the steps involved in repairing a rubber good?

Surface Preparation

- Clean the damaged area with a solvent to remove any dirt or debris.

- Sand the damaged area to create a smooth surface for the patch.

Patching

- Cut a patch of rubber that is slightly larger than the damaged area.

- Apply a thin layer of adhesive to the patch and the damaged area.

- Press the patch into place and smooth out any wrinkles.

Curing

- Allow the patch to cure for the amount of time specified by the adhesive manufacturer.

- Test the repair by inflating the rubber good or applying pressure to the patched area.

3. What are some of the common problems that can occur when repairing rubber goods?

- The patch may not adhere properly to the damaged area.

- The patch may leak air or fluid.

- The repair may not be strong enough to withstand the intended use.

4. What are some of the safety precautions that should be taken when repairing rubber goods?

- Wear gloves and eye protection when working with solvents and adhesives.

- Use a well-ventilated area when working with solvents and adhesives.

- Do not smoke or eat while working with solvents and adhesives.

- Keep solvents and adhesives away from children and pets.

5. What are some of the tools and equipment that are used to repair rubber goods?

- Rubber repair kit

- Solvent

- Adhesive

- Patch

- Sandpaper

- Knife

- Scissors

6. What are some of the different industries that use rubber goods repairers?

- Automotive

- Aerospace

- Industrial

- Medical

7. What are the different types of rubber repair techniques?

- Hot vulcanization

- Cold vulcanization

- Self-vulcanization

8. What are the different types of rubber repair materials?

- Rubber patches

- Rubber cement

- Rubber tape

- Rubber sealant

9. What are the different types of rubber repair equipment?

- Rubber repair press

- Rubber repair vulcanizer

- Rubber repair buffer

10. What are the different types of rubber repair safety precautions?

- Wear gloves

- Wear eye protection

- Use ventilation

- Avoid sparks

11. What is the most important thing to consider when repairing a rubber good?

- The type of rubber

- The extent of the damage

- The intended use of the rubber good

12. What are the different types of rubber repair warranties?

- Labor warranty

- Parts warranty

- Full warranty

13. What are the different types of rubber repair certifications?

- Rubber Repair Technician Certification

- Rubber Repair Specialist Certification

- Rubber Repair Master Certification

14. What are the different types of rubber repair training programs?

- Rubber Repair Technician Training Program

- Rubber Repair Specialist Training Program

- Rubber Repair Master Training Program

15. What are the different types of rubber repair jobs?

- Rubber Repair Technician

- Rubber Repair Specialist

- Rubber Repair Manager

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Goods Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Goods Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rubber Goods Repairer, also known as a Rubber Vulcanizer, is responsible for repairing and rebuilding products made from rubber. Their responsibilities include assessing damage, selecting appropriate repair methods, and utilizing specialized tools and techniques to ensure the safe and efficient operation of rubber goods.

1. Inspecting and Assessing Damage

Identifying and evaluating the extent of damage caused to rubber goods, considering factors such as location, type of damage, and potential impact on functionality.

- Examining rubber products for punctures, tears, cuts, and other defects.

- Assessing the severity of damage, including its depth, extent, and any underlying issues.

2. Selecting and Implementing Repair Methods

Determining the most appropriate repair method based on the type of damage, the materials involved, and the desired level of durability. Using specialized knowledge and experience to select the best approach.

- Vulcanizing rubber using heat and pressure to bond new rubber to the damaged area.

- Applying patches or inserts to cover and reinforce damaged sections.

3. Utilizing Specialized Tools and Techniques

Operating various tools and equipment, including vulcanizing machines, buffers, and hand tools to repair rubber goods. Utilizing specialized techniques, such as hot and cold vulcanization, to ensure proper bonding.

- Using vulcanizing machines to apply heat and pressure to bond rubber materials.

- Employing buffers to smooth and finish repaired surfaces.

4. Ensuring Safety and Quality

Maintaining a safe work environment by following proper safety protocols and using appropriate protective gear. Adhering to industry standards and quality control measures to ensure repairs meet specifications.

- Wearing appropriate safety gear, such as gloves, goggles, and respirators.

- Following established procedures and using calibrated equipment to ensure accurate repairs.

Interview Tips

To ace the interview for a Rubber Goods Repairer position, it is crucial to demonstrate a strong understanding of the job responsibilities, technical skills, and safety protocols. Here are some preparation tips to help you stand out:

1. Research the Company and Industry

Familiarize yourself with the company’s background, products, and industry trends. Understanding the company’s values and goals will show the interviewer that you are genuinely interested in the position and have taken the time to learn about their organization.

- Visit the company’s website and read their mission statement, company profile, and recent news.

- Research industry publications and attend relevant workshops or conferences to stay updated on the latest trends.

2. Highlight Your Technical Skills

Emphasize your proficiency in rubber repair techniques, including vulcanization, patching, and mold repair. Provide specific examples of your work and the outcomes you achieved.

- Mention any specialized certifications, such as rubber repair training or industry-recognized credentials.

- Prepare examples of complex repairs you have successfully completed, demonstrating your problem-solving abilities and attention to detail.

3. Showcase Your Safety Awareness

подчеркнуть ваше соблюдение правил техники безопасности и знание отраслевых стандартов. Продемонстрируйте свое понимание рисков и мер предосторожности, связанных с ремонтом резиновых изделий.

- Explain your experience in using safety equipment and following established safety protocols.

- Highlight your knowledge of hazardous materials handling and proper disposal procedures.

4. Practice Your Communication Skills

Prepare clear and concise answers to common interview questions. Practice articulating your qualifications, experience, and career goals in a professional and engaging manner.

- Role-play interview scenarios with a friend or family member to improve your response quality.

- Record yourself answering questions and review it to identify areas for improvement.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Rubber Goods Repairer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Rubber Goods Repairer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.