Are you gearing up for a career in Rubber Goods Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rubber Goods Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

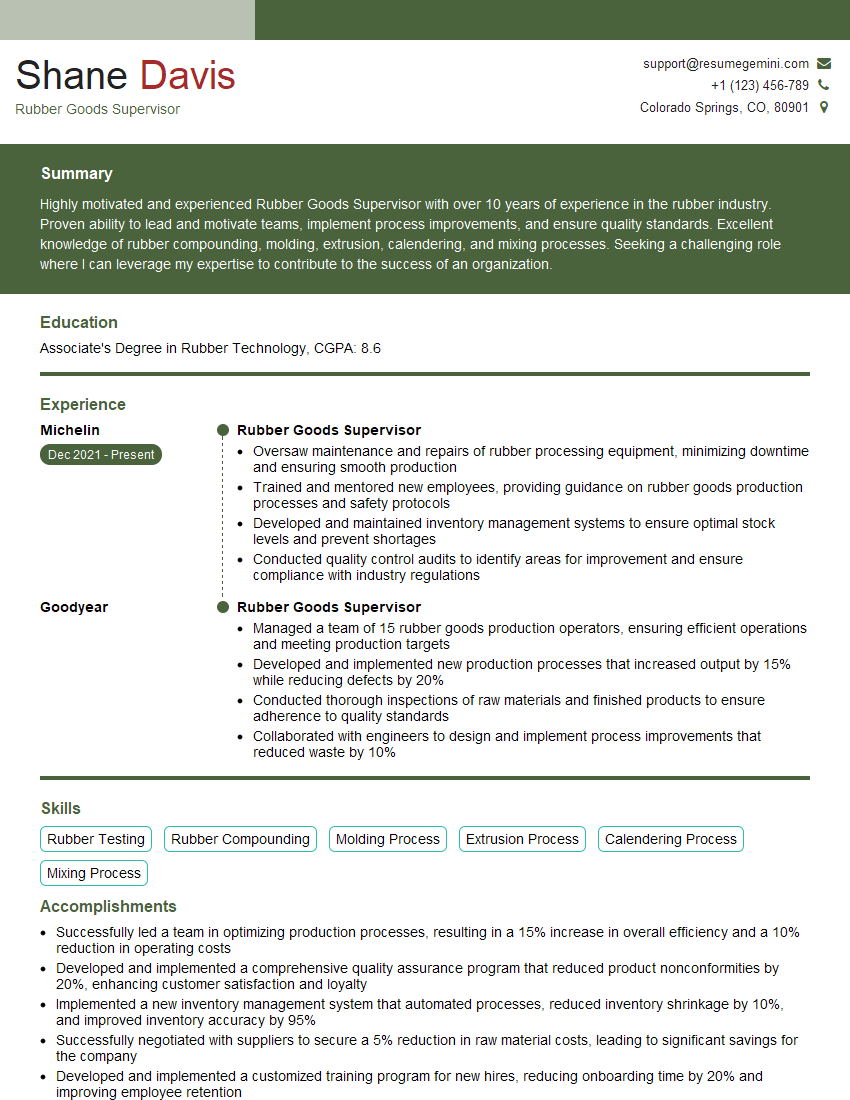

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Goods Supervisor

1. How do you ensure the quality of rubber products before they are shipped?

- Conduct visual inspections to check for defects, such as cracks, holes, or discoloration.

- Perform physical tests to measure hardness, tensile strength, and elongation.

- Carry out chemical tests to verify the composition and purity of the rubber.

- Review production records and quality control documentation.

- Implement statistical process control techniques to monitor and improve quality.

2. What are the key factors to consider when determining the appropriate type of rubber for a particular application?

Durability

- Consider the intended use and the environmental conditions the rubber will be exposed to.

- Select a rubber compound with high tensile strength, tear resistance, and abrasion resistance.

Flexibility

- Determine the required range of motion and flexibility.

- Choose a rubber compound with low modulus and high elongation.

Resistance to chemicals and temperature

- Identify the chemicals and temperature range that the rubber will be subjected to.

- Select a rubber compound with appropriate chemical resistance and heat resistance.

3. Discuss the safety precautions that you would take when working with rubber chemicals and materials?

- Wear appropriate personal protective equipment, including gloves, goggles, and a respirator.

- Handle chemicals in a well-ventilated area.

- Follow proper storage and disposal procedures.

- Be aware of the potential health hazards associated with rubber chemicals.

- Receive training on the safe handling of rubber chemicals and materials.

4. How do you manage a team of rubber goods production operators to meet production targets and ensure product quality?

- Provide clear instructions and expectations.

- Monitor performance and provide feedback.

- Identify and address training needs.

- Foster a positive and collaborative work environment.

- Empower team members to make decisions and solve problems.

5. What are the latest industry trends and advancements in rubber production and technology?

- Increased use of synthetic rubber compounds.

- Development of new rubber additives and fillers.

- Advancements in rubber processing technology.

- Growing demand for sustainable rubber production.

- Increased use of automation and robotics in rubber manufacturing.

6. How would you handle a situation where a customer complains about the quality of a rubber product?

- Listen attentively to the customer’s complaint.

- Inspect the product to verify the issue.

- Determine the root cause of the problem.

- Work with the production team to implement corrective actions.

- Communicate with the customer throughout the process and provide updates.

7. Describe your experience in implementing lean manufacturing principles in a rubber production environment.

- Identified and eliminated waste throughout the production process.

- Improved production efficiency and reduced lead times.

- Reduced inventory levels and increased flexibility.

- Engaged the workforce in continuous improvement initiatives.

- Achieved significant cost savings and improved customer satisfaction.

8. How do you stay up-to-date on the latest industry standards and best practices for rubber production?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Network with other rubber professionals.

- Participate in industry associations.

- Seek out training and certification opportunities.

9. Describe a challenge you faced in your previous role as a Rubber Goods Supervisor and how you overcame it.

- Led a team to resolve a quality issue that was impacting customer satisfaction.

- Successfully implemented a new production process that resulted in increased efficiency.

- Overcame a production bottleneck by working closely with suppliers and logistics providers.

- Motivated and trained a team of operators to achieve record-breaking production levels.

- Collaborated with engineers to develop a new product that met specific customer requirements.

10. How do you ensure that your team is properly trained and certified to handle rubber production equipment and materials?

- Develop and implement a comprehensive training program.

- Provide hands-on training and on-the-job experience.

- Monitor and evaluate training effectiveness.

- Maintain records of training and certifications.

- Encourage team members to pursue professional development opportunities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Goods Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Goods Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rubber Goods Supervisor is responsible for overseeing and managing the production of rubber goods in a manufacturing environment. Key responsibilities include:

1. Production Management

Ensuring that production targets are met while maintaining high quality standards.

- Monitoring production lines, identifying and resolving bottlenecks

- Coordinating with production staff to ensure efficient workflow

2. Quality Control

Establishing and implementing quality control measures to ensure product quality.

- Inspecting raw materials and finished products

- Investigating and resolving quality issues

3. Inventory Management

Maintaining inventory levels of raw materials and finished goods.

- Ordering raw materials and managing stock

- Monitoring inventory levels and implementing inventory control systems

4. Health and Safety

Ensuring a safe and healthy work environment for employees.

- Developing and enforcing safety protocols

- Monitoring compliance with safety regulations

Interview Tips

Preparing for an interview can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company

Take the time to learn about the company’s history, products, and culture. This will help you understand the role and the company’s expectations.

- Visit the company website

- Read industry news and articles

2. Practice Your Answers

Anticipate common interview questions and practice your answers. This will help you feel more confident and prepared during the interview.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

- Get feedback from friends or family

3. Prepare Questions for the Interviewer

Asking thoughtful questions shows that you are engaged and interested in the role. It also gives you an opportunity to learn more about the company and the position.

- Ask about the company’s growth plans

- Inquire about opportunities for professional development

4. Dress Professionally

First impressions matter, so make sure you dress appropriately for the interview. This means wearing clean, pressed clothes that are suitable for a business environment.

- Choose conservative colors and styles

- Make sure your clothes fit well

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rubber Goods Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.