Are you gearing up for a career in Rubber Printing Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rubber Printing Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

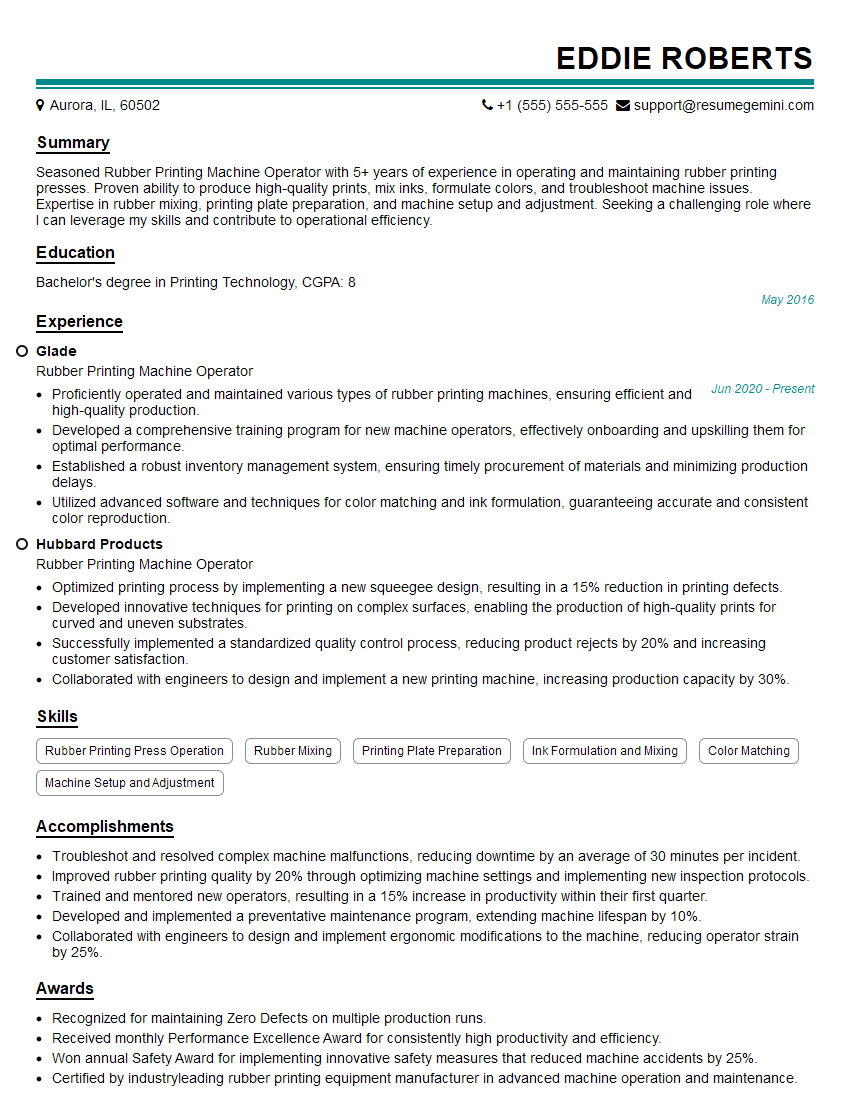

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Printing Machine Operator

1. Describe the steps involved in preparing a rubber printing machine for operation.

The preparation steps include:

- Inspecting the machine for any damage or wear.

- Checking the ink supply and ensuring it is adequate.

- Adjusting the machine settings, such as speed, pressure, and temperature.

- Loading the rubber printing plate onto the machine.

- Performing a test run to ensure the machine is operating correctly.

2. How do you identify and troubleshoot common problems that occur with rubber printing machines?

Troubleshooting Ink Issues

- Check ink viscosity and adjust if necessary.

- Inspect ink lines for clogs or leaks.

- Clean printing head and nozzles regularly.

Troubleshooting Printing Defects

- Check plate alignment and adjust if needed.

- Inspect rubber blanket for damage or wear.

- Adjust printing pressure and speed.

3. What are the safety precautions that should be taken when operating a rubber printing machine?

Safety precautions include:

- Wearing appropriate personal protective equipment (PPE).

- Keeping the work area clean and free of tripping hazards.

- Never reaching into the machine while it is running.

- Following lock-out/tag-out procedures during maintenance.

- Being aware of the location of emergency stop buttons.

4. How do you maintain and clean a rubber printing machine?

Maintenance and cleaning involve:

- Regularly cleaning the machine with solvents and lubricants.

- Inspecting and replacing worn or damaged parts.

- Performing periodic maintenance checks, such as checking belt tension and oil levels.

- Following the manufacturer’s recommended maintenance schedule.

5. What techniques do you use to achieve high-quality prints on a rubber printing machine?

Techniques for high-quality prints include:

- Optimizing ink viscosity and coverage.

- Selecting the appropriate rubber printing plate material.

- Adjusting printing pressure and speed to suit the substrate.

- Using proper drying techniques to prevent smudging.

- Inspecting printed products to ensure quality standards are met.

6. What experience do you have with different types of rubber printing machines?

I have experience with various types of rubber printing machines, including:

- Pad printing machines

- Screen printing machines

- Flexographic printing machines

- Rotary printing machines

7. How do you handle rush orders or unexpected printing problems?

To handle rush orders, I prioritize tasks and adjust my schedule to meet deadlines. For unexpected problems, I troubleshoot quickly, consult with colleagues or supervisors, and find solutions to minimize disruptions.

8. How do you ensure consistency and accuracy in the printing process?

I follow standardized operating procedures, maintain equipment regularly, and conduct quality control checks throughout the printing process. I also use measurement tools to ensure accuracy and consistency.

9. What is your experience with color matching and ink management?

I have a good understanding of color theory and ink mixing. I use spectrophotometers to ensure accurate color matching and manage ink inventory to minimize waste and maintain quality.

10. What is your knowledge of different substrates used in rubber printing?

I am familiar with a range of substrates, including paper, plastic, metal, glass, and textiles. I understand their printing characteristics and adjust machine settings accordingly to achieve optimal results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Printing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Printing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A rubber printing machine operator plays a pivotal role in the production process, operating sophisticated machines to print images and patterns onto a wide range of materials. Their responsibilities encompass several crucial tasks:

1. Machine Operation and Maintenance

The core responsibility of a rubber printing machine operator involves the proficient operation of rubber printing machines. They ensure precise alignment of printing plates and materials, meticulously adjusting printing parameters to achieve optimal print quality. Furthermore, they perform routine maintenance tasks, including cleaning and lubricating machinery components, to maintain peak performance and prevent breakdowns.

- Review production orders, set up machines, and load printing materials.

- Monitor print quality, make adjustments as needed, and ensure consistency.

- Conduct regular maintenance, including cleaning, lubricating, and minor repairs.

2. Quality Control

Rubber printing machine operators are responsible for maintaining high standards of print quality. They meticulously inspect printed products, ensuring that they meet specifications and customer requirements. They promptly identify and rectify any defects or inconsistencies.

- Inspect printed materials for accuracy, clarity, and color matching.

- Identify and troubleshoot printing defects, implementing corrective actions.

- Maintain records of quality checks and production output.

3. Material Handling

Effective material handling is essential for efficient printing operations. Rubber printing machine operators carefully handle printing materials, ensuring that they are properly loaded, aligned, and unloaded. They also manage raw materials and finished products, maintaining a clean and organized work area.

- Unload and load printing materials, ensuring proper alignment and tension.

- Maintain inventory of raw materials and finished products, ensuring sufficient supplies.

- Follow safety protocols when handling printing materials and chemicals.

4. Safety and Compliance

Rubber printing machine operators prioritize safety in the workplace, adhering to established safety regulations and guidelines. They wear appropriate personal protective equipment, handle chemicals safely, and maintain a clean and hazard-free work environment.

- Follow safety protocols, wear personal protective equipment, and maintain a clean work area.

- Handle chemicals safely and dispose of waste according to regulations.

- Report any safety hazards or accidents promptly to supervisors.

Interview Tips

Preparing for an interview for a rubber printing machine operator position requires thorough preparation and a strategic approach. Here are some valuable tips to help you ace the interview:

1. Research the Company and Industry

Demonstrating knowledge about the company and the rubber printing industry shows genuine interest and enthusiasm. Visit the company’s website, research their products and services, and familiarize yourself with industry trends. This knowledge will help you answer questions intelligently and engage in meaningful conversations.

- Visit the company’s website and social media pages to learn about their history, mission, and values.

- Research the rubber printing industry, including key players, technologies, and market trends.

2. Practice Answering Common Interview Questions

Anticipating and preparing for common interview questions can boost your confidence and enhance your performance. Practice answering questions related to your technical skills, experience, and problem-solving abilities. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses effectively.

- Prepare answers to questions about your experience operating rubber printing machines, maintaining equipment, and handling materials.

- Practice describing your problem-solving skills and how you have overcome challenges in the past.

3. Highlight Your Skills and Experience

Tailor your resume and cover letter to emphasize skills and experience that align with the job requirements. Quantify your accomplishments whenever possible, providing specific examples of your contributions to previous roles.

- Highlight your technical skills, such as proficiency in operating rubber printing machines, color matching, and quality control.

- Emphasize your experience in maintaining and troubleshooting equipment, as well as your ability to work in a fast-paced production environment.

4. Prepare Questions to Ask

Asking thoughtful questions demonstrates your engagement and interest in the position. Prepare a few intelligent questions about the company’s operations, growth plans, or the specific role you are interviewing for. Asking questions also gives you an opportunity to clarify any details or gain insights into the company culture.

- Ask about the company’s production processes and quality standards.

- Inquire about opportunities for professional development and career advancement.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally, arrive on time for your interview, and maintain a positive and enthusiastic demeanor. Punctuality and appropriate attire convey respect for the interviewer’s time and demonstrate your commitment to the opportunity.

- Choose business attire that is clean, pressed, and fits well.

- Arrive at the interview location 10-15 minutes early to allow for any unexpected delays.

6. Follow-Up After the Interview

Following up after the interview is a courteous and professional practice. Send a thank-you note to the interviewer, reiterating your interest in the position and thanking them for their time. You can also use this opportunity to address any points you may have forgotten to mention during the interview.

- Send a thank-you note within 24 hours of the interview.

- Reiterate your key qualifications and why you are a suitable candidate for the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rubber Printing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.