Are you gearing up for a career in Rubber Stamp Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rubber Stamp Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

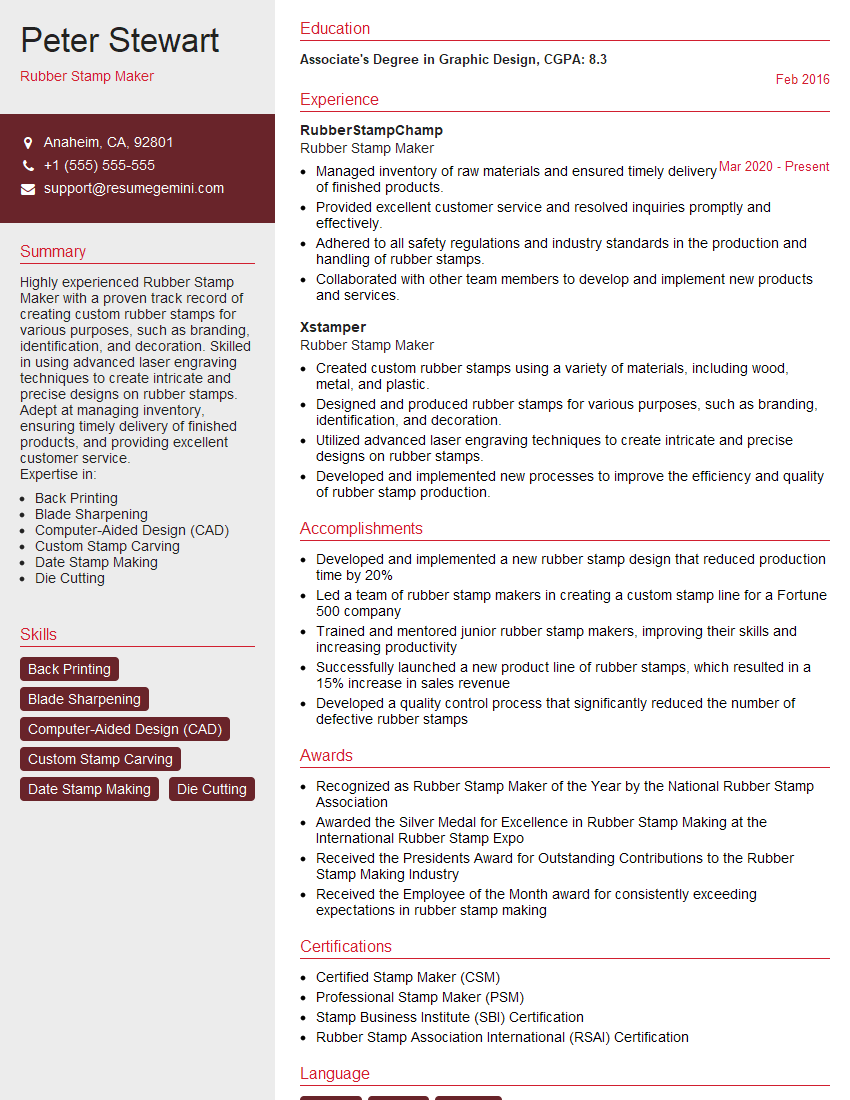

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Stamp Maker

1. What are the different types of rubber stamps and their uses?

Rubber stamps are categorized into various types based on their intended applications. Some common types and their uses are:

- Traditional Stamps: Handheld stamps with a carved rubber surface, used for marking documents, envelopes, and packages.

- Self-Inking Stamps: Stamps that have an internal ink reservoir, eliminating the need for a separate ink pad.

- Pre-Inked Stamps: Stamps with a permanent ink supply that does not require re-inking.

- Dater Stamps: Stamps that imprint the current date alongside custom messages or logos.

- Numbering Stamps: Stamps used for sequentially numbering documents or objects.

2. What factors should be considered when selecting the right rubber for stamp making?

Factors to Consider

- Durability: The rubber’s ability to withstand repeated use and wear.

- Hardness: Suitable hardness to produce clear and precise impressions.

- Compatibility with Ink: The rubber’s ability to absorb and transfer ink effectively.

- Price: The cost of the rubber versus its performance and longevity.

Common Rubber Types

- Natural Rubber: Durable and cost-effective, but susceptible to heat and chemicals.

- Synthetic Rubber: More resistant to heat and chemicals, but potentially more expensive.

- Silicone Rubber: Heat-resistant, but may require special inks.

3. What tools and equipment are necessary for rubber stamp making?

The essential tools and equipment for rubber stamp making include:

- Rubber Carving Tools: Knives, gouges, and chisels for carving the rubber.

- Ink: Special ink formulated for rubber stamps, available in various colors.

- Carving Block: A firm surface on which the rubber is mounted for carving.

- Adhesive: Adhesive for mounting the carved rubber onto the stamp base.

- Stamp Base: A handle or mount for holding the rubber stamp.

- Safety Goggles: To protect eyes while carving.

4. Describe the process of designing and creating a custom rubber stamp.

Creating a custom rubber stamp involves the following steps:

- Design: Sketch or create a digital design of the desired stamp.

- Carving: Transfer the design onto the rubber and carve it using carving tools.

- Mounting: Adhere the carved rubber onto the stamp base.

- Inking: Apply ink to the carved rubber surface.

- Testing: Make test prints to ensure the stamp produces clear and sharp impressions.

5. What techniques can be used to create special effects on rubber stamps?

Various techniques can enhance the visual appeal of rubber stamps, including:

- Multiple Layers: Carving multiple layers of rubber to create depth and shadows.

- Texturing: Using different carving tools to create textures, such as wood grain or fabric patterns.

- Shading: Carving varying depths to create gradients and shading effects.

- Coloring: Applying multiple colors of ink to create multi-colored impressions.

- Embossing: Raising parts of the stamp design to create a raised impression on paper.

6. How do you ensure the accuracy and precision of rubber stamp carvings?

To achieve accurate and precise carvings, it is important to:

- Use High-Quality Tools: Invest in sharp and well-maintained carving tools.

- Plan Carefully: Plan the carving design thoroughly before starting.

- Carve Gradually: Remove material gradually and carefully to avoid over-carving.

- Use Magnification: Use a magnifying glass or loupe to enhance precision.

- Practice Regularly: Practice regularly to improve hand-eye coordination and carving skills.

7. What are the common challenges faced in rubber stamp making and how do you overcome them?

Challenges

- Tearing Rubber: Using too much force or sharp tools can tear the rubber.

- Uneven Carving: Inconsistent carving can result in blurred impressions.

- Poor Ink Absorption: Improper rubber selection or carving techniques can affect ink absorption.

Solutions

- Use Sharp Tools: Regularly sharpen carving tools to ensure clean cuts.

- Carve Slowly: Slowly and carefully carve the rubber, avoiding excessive pressure.

- Select Suitable Rubber: Choose rubber specifically formulated for stamp making.

8. How do you handle customer requests for complex or intricate rubber stamp designs?

For complex designs, I approach them as follows:

- Consultation: Discuss the design requirements with the customer to fully understand their vision.

- Sketches: Create sketches or digital mockups to communicate the proposed design.

- Proofing: Provide proofs of the carved stamp to the customer for approval before finalizing the design.

- Collaboration: Collaborate with the customer throughout the process to ensure their satisfaction.

9. What are the safety precautions to observe when making rubber stamps?

To ensure safety while making rubber stamps, it is essential to follow these precautions:

- Use Sharp Tools with Care: Handle carving tools carefully to avoid cuts or injuries.

- Wear Safety Goggles: Wear safety goggles to protect eyes from flying debris.

- Ventilate Workspace: Work in a well-ventilated area to avoid inhaling harmful fumes from rubber carving.

- Dispose of Rubber Scraps: Properly dispose of rubber scraps to prevent ingestion or inhalation.

10. How do you stay updated with the latest techniques and trends in rubber stamp making?

To stay current in the field, I utilize various resources:

- Attend Workshops and Seminars: Participate in workshops or seminars to learn about new techniques and trends.

- Read Industry Publications: Subscribe to trade magazines and online forums to stay informed about industry advancements.

- Experiment with New Materials: Explore different rubber types and inks to discover their unique properties and applications.

- Engage with Online Communities: Join online communities and forums to connect with other rubber stamp makers and share knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Stamp Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Stamp Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rubber Stamp Maker is responsible for creating custom rubber stamps for various purposes. They use specialized equipment and techniques to design and produce stamps that meet the specific requirements of their clients. Their key responsibilities include:

1. Client Consultation and Design Development:

Meeting with clients to discuss their needs and preferences for the rubber stamp. Guiding clients in selecting the appropriate stamp type, size, and design elements. Creating custom designs based on client specifications or using pre-existing templates.

2. Stamp Production:

Using specialized software to create digital designs for the stamps. Converting digital designs into physical stamps using laser engraving or other production techniques. Ensuring the accuracy and quality of the produced stamps.

3. Quality Control and Maintenance:

Inspecting produced stamps for defects or errors. Maintaining and calibrating equipment to ensure optimal performance. Troubleshooting any issues that arise during production.

4. Administrative Tasks:

Maintaining records of client orders and production details. Providing customer support and resolving any inquiries or complaints. Keeping the work area organized and adhering to safety protocols.

Interview Tips

Preparing for an interview for a Rubber Stamp Maker position requires a combination of technical proficiency, industry knowledge, and effective communication skills. Here are some tips to help candidates ace the interview:

1. Research the Company and the Role:

Thoroughly research the company you are applying to, including their products, services, and industry reputation. Familiarize yourself with the specific requirements and responsibilities of the Rubber Stamp Maker role.

2. Showcase Technical Skills and Expertise:

Highlight your proficiency in using design software and stamp production equipment. Provide examples of your previous work, demonstrating your ability to create high-quality custom stamps. Discuss your knowledge of different stamp types, materials, and applications.

3. Emphasize Attention to Detail and Quality:

Emphasize your meticulous nature and commitment to producing error-free stamps. Share examples of how you ensure accuracy and quality in your work. Explain your understanding of quality control processes and industry standards.

4. Highlight Customer Service Skills:

Rubber Stamp Makers often interact directly with clients. Showcase your excellent communication and interpersonal skills. Explain how you build strong relationships with clients, understand their needs, and provide exceptional customer service.

5. Prepare Questions to Ask:

Preparing thoughtful questions to ask the interviewer demonstrates your interest in the role and the company. It also allows you to gather additional information about the job and the company culture. Ask questions about growth opportunities, training programs, and the company’s commitment to quality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rubber Stamp Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!