Feeling lost in a sea of interview questions? Landed that dream interview for Rubber Stamps and Dies Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Rubber Stamps and Dies Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

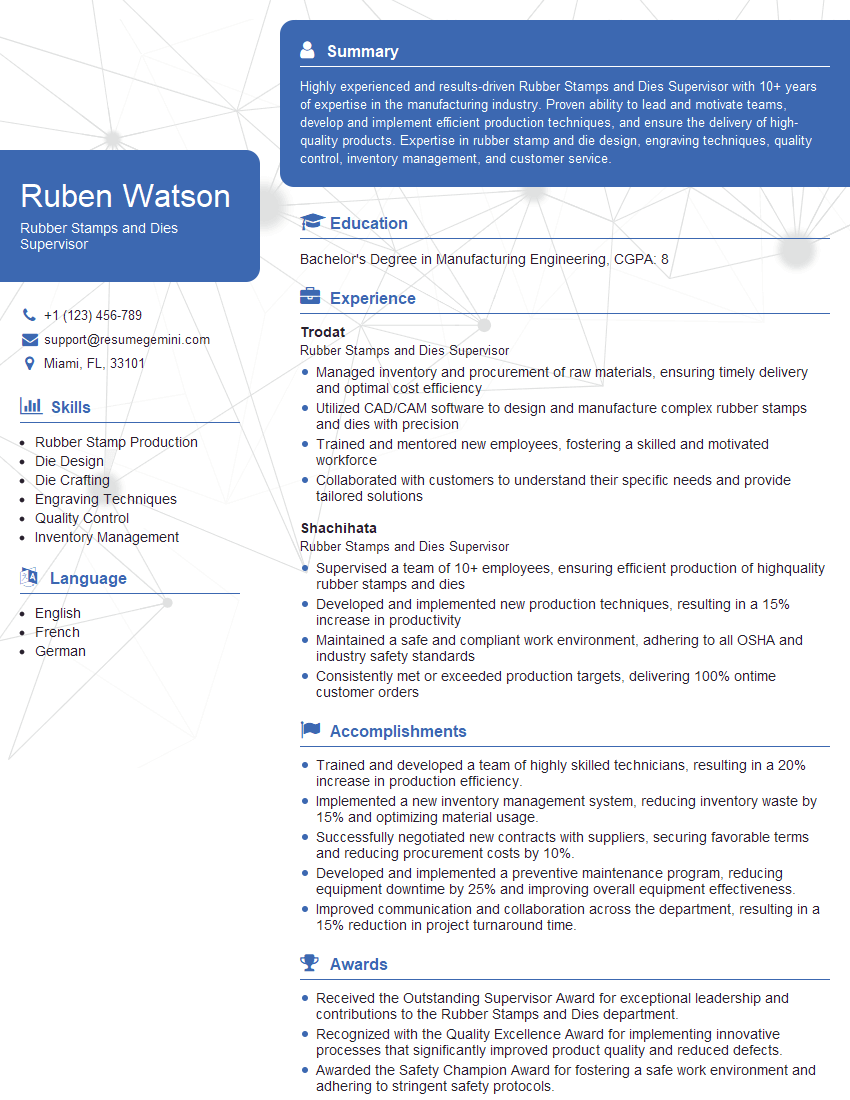

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Stamps and Dies Supervisor

1. Describe the process of creating a rubber stamp from start to finish.

The process of creating a rubber stamp from start to finish involves the following steps:

- Design creation: The first step is to create a design for the stamp. This can be done using a computer program or by hand.

- Die preparation: Once the design is complete, a die is prepared. The die is a metal mold that is used to create the stamp.

- Rubber preparation: The next step is to prepare the rubber. The rubber is a special type of rubber that is used for making stamps.

- Mounting the rubber: The rubber is then mounted on the die. This is done using a special adhesive.

- Curing the rubber: The rubber is then cured. This is done by heating the rubber to a specific temperature.

- Testing the stamp: Once the rubber is cured, the stamp is tested. This is done to ensure that the stamp is working properly.

2. What are the different types of rubber stamps?

Types of Rubber Stamps

- Wood Mounted: These stamps are mounted on a wooden block. They are the most common type of stamp.

- Self-Inking: These stamps have a built-in ink pad. This makes them easy to use and they do not require a separate ink pad.

- Pre-Inked: These stamps are pre-inked and do not require an ink pad. They are a good option for high-volume stamping.

Uses of Rubber Stamps

- Office use: Rubber stamps are often used in the office for stamping documents, letters, and envelopes.

- Craft use: Rubber stamps are also popular for crafting. They can be used to decorate paper, fabric, and other materials.

- Commercial use: Rubber stamps are also used for commercial purposes, such as branding and marketing.

3. What are the factors to consider when choosing a rubber stamp?

When choosing a rubber stamp, there are several factors to consider:

- Purpose: The first thing to consider is the purpose of the stamp. What will you be using the stamp for?

- Size: The size of the stamp is also important. Make sure the stamp is large enough to fit your needs.

- Type: There are several different types of rubber stamps. Choose the type of stamp that is best for your needs.

- Price: The price of the stamp is also a factor to consider. Make sure you get a stamp that is affordable for you.

4. How can you extend the life of a rubber stamp?

There are several things you can do to extend the life of a rubber stamp:

- Clean the stamp after each use: This will remove any ink or debris that could damage the stamp.

- Store the stamp in a cool, dry place: Heat and moisture can damage the stamp.

- Do not use the stamp on rough surfaces: This could damage the stamp.

- Be careful not to drop the stamp: Dropping the stamp could damage it.

5. What are the safety precautions that should be taken when using a rubber stamp?

When using a rubber stamp, there are several safety precautions that should be taken:

- Do not use the stamp near open flames: The rubber stamp could catch fire.

- Do not use the stamp on hot surfaces: The rubber stamp could melt.

- Do not use the stamp on wet surfaces: The rubber stamp could become slippery and difficult to handle.

- Do not use the stamp if it is damaged: A damaged stamp could cause injury.

6. What are the different materials used to make rubber stamps?

Rubber stamps can be made from a variety of materials, including:

- Natural rubber: Natural rubber is a durable and flexible material that is often used to make rubber stamps.

- Synthetic rubber: Synthetic rubber is a man-made material that is often used to make rubber stamps. It is more resistant to wear and tear than natural rubber.

- Silicone: Silicone is a synthetic material that is often used to make rubber stamps. It is very durable and can withstand high temperatures.

- Photopolymer: Photopolymer is a light-sensitive material that is often used to make rubber stamps. It is very precise and can create very detailed images.

7. What are the different methods used to make rubber stamps?

There are several different methods used to make rubber stamps, including:

- Hand carving: Hand carving is a traditional method of making rubber stamps. It involves using a sharp knife to carve the design into a block of rubber.

- Laser engraving: Laser engraving is a modern method of making rubber stamps. It involves using a laser to engrave the design into a block of rubber.

- Photopolymer printing: Photopolymer printing is a method of making rubber stamps that involves using a light-sensitive material to create the design.

8. What are the different types of ink used for rubber stamps?

There are several different types of ink used for rubber stamps, including:

- Water-based ink: Water-based ink is a type of ink that is made with water and dyes. It is easy to clean up and is not toxic.

- Oil-based ink: Oil-based ink is a type of ink that is made with oil and pigments. It is more durable than water-based ink, but it is also more difficult to clean up and is toxic.

- Solvent-based ink: Solvent-based ink is a type of ink that is made with solvents and pigments. It is very durable and is resistant to water and fading.

9. What are the different applications of rubber stamps?

Rubber stamps have a wide variety of applications, including:

- Office use: Rubber stamps are often used in the office for stamping documents, letters, and envelopes.

- Craft use: Rubber stamps are also popular for crafting. They can be used to decorate paper, fabric, and other materials.

- Commercial use: Rubber stamps are also used for commercial purposes, such as branding and marketing.

10. What are the advantages of using rubber stamps?

There are several advantages to using rubber stamps, including:

- Convenience: Rubber stamps are very convenient to use. They can be used to quickly and easily stamp documents, letters, and other materials.

- Durability: Rubber stamps are very durable. They can withstand repeated use without becoming damaged.

- Affordability: Rubber stamps are very affordable. They are a cost-effective way to add a professional touch to your documents and materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Stamps and Dies Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Stamps and Dies Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rubber Stamps and Dies Supervisors play a crucial role in the production of rubber stamps and dies, ensuring the efficiency and accuracy of the operation. Their key responsibilities include:

1. Production Management

Supervising and coordinating the production process, including scheduling, dispatching, and monitoring production activities.

- Developing and implementing production plans to optimize efficiency and output.

- Allocating resources, such as personnel, equipment, and materials, to meet production targets.

2. Quality Control

Inspecting and ensuring the quality of rubber stamps and dies produced.

- Establishing and maintaining quality standards for products and processes.

- Conducting regular inspections and audits to identify and address quality issues.

3. Employee Supervision

Directing, training, and motivating a team of employees involved in rubber stamp and die production.

- Hiring, training, and developing employees to enhance their skills and productivity.

- Providing clear instructions, guidance, and support to ensure employees perform their tasks effectively.

4. Safety Management

Ensuring a safe and compliant work environment by implementing safety protocols and procedures.

- Identifying and mitigating potential hazards associated with rubber stamp and die production.

- Training employees on safety practices and ensuring compliance with safety regulations.

Interview Preparation Tips

Preparing thoroughly for an interview is essential to showcasing your qualifications and impressing potential employers. Here are some tips to help you ace your interview for a Rubber Stamps and Dies Supervisor position:

1. Research the Company

Gain a deep understanding of the company’s history, products, services, and industry position. This knowledge will allow you to align your skills and experience with the company’s specific needs.

2. Practice Common Interview Questions

Anticipate typical interview questions and prepare thoughtful responses that highlight your relevant skills and accomplishments. Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples that demonstrate your abilities.

3. Highlight Your Production Management Skills

Emphasize your expertise in planning, scheduling, and optimizing production processes. Quantify your achievements using metrics such as increased efficiency or reduced production time.

4. Showcase Your Quality Control Experience

Demonstrate your understanding of quality standards and your ability to implement and enforce them. Describe your role in identifying and resolving quality issues, resulting in improved product quality.

5. Share Your Employee Supervision Strategies

Explain your approach to employee supervision, focusing on motivating and developing team members. Provide examples of how you have successfully led and trained employees to achieve their full potential.

6. Emphasize Your Safety Leadership

Highlight your knowledge of safety regulations and your commitment to maintaining a safe work environment. Describe your experience in developing and implementing safety protocols, ensuring the well-being of your team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rubber Stamps and Dies Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!