Feeling lost in a sea of interview questions? Landed that dream interview for Rubber Tester but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Rubber Tester interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

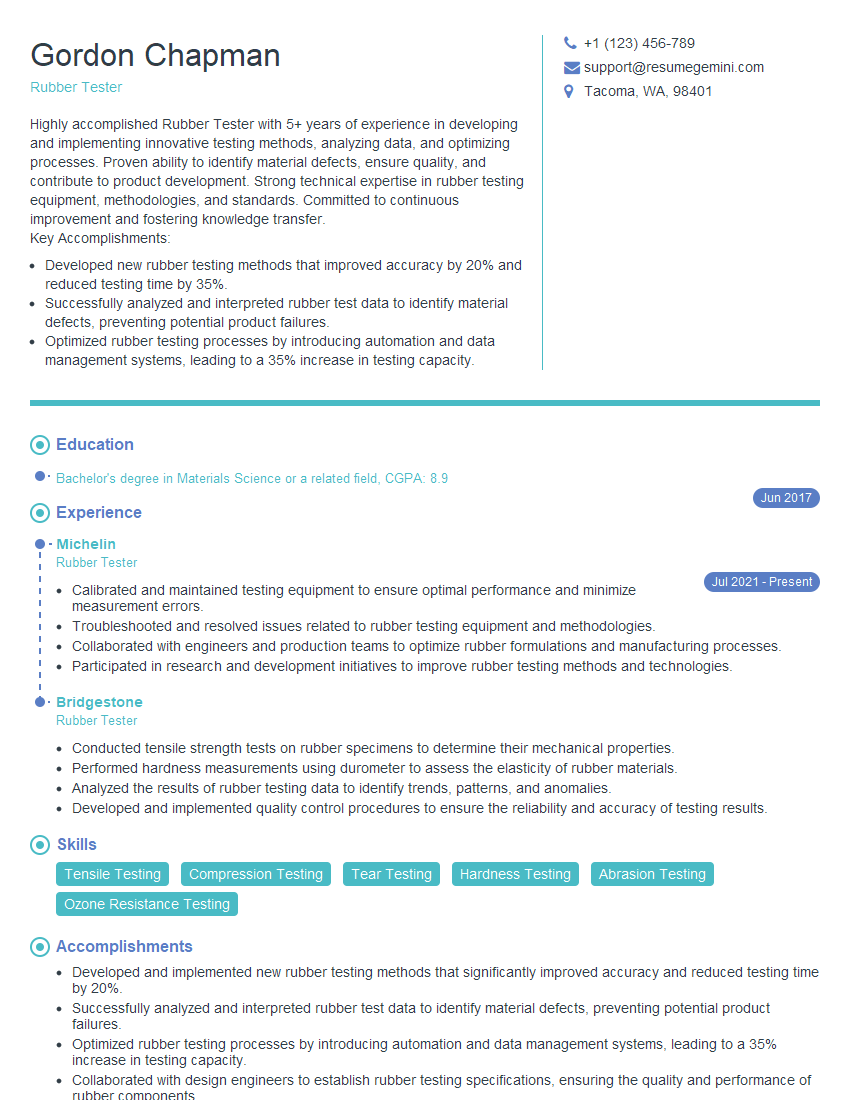

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Tester

1. What are the different types of rubber testing methods and their applications?

Answer:

- Tensile testing: Measures the strength and elongation of rubber under tension. Used for quality control, product development, and research.

- Compression testing: Measures the resistance of rubber to compression. Used for testing gaskets, seals, and other rubber components.

- Tear testing: Measures the resistance of rubber to tearing. Used for testing tires, belts, and other rubber products that are subject to tearing forces.

- Abrasion testing: Measures the resistance of rubber to wear and abrasion. Used for testing tires, hoses, and other rubber products that are exposed to abrasive environments.

- Resilience testing: Measures the ability of rubber to recover its shape after being deformed. Used for testing rubber components that are subjected to repeated stress and strain.

2. Describe the process of conducting a tensile test on rubber.

Preparation:

- Cut a dumbbell-shaped specimen from the rubber sample.

- Mark the gauge length on the specimen.

- Mount the specimen in the tensile testing machine.

Procedure:

- Apply a controlled tensile load to the specimen at a constant rate.

- Record the load and elongation data as the specimen stretches.

- Continue testing until the specimen breaks.

Analysis:

- Calculate the tensile strength (maximum load / original cross-sectional area).

- Calculate the elongation at break (final length – original length / original length).

- Plot the stress-strain curve and analyze the results.

3. What are the different types of tensile testing machines and their pros and cons?

Answer:

- Constant-rate-of-extension (CRE) machines: Apply a constant rate of elongation to the specimen. Pros: Simple and inexpensive. Cons: Can be slow and may not be suitable for testing highly elastic materials.

- Constant-rate-of-load (CRL) machines: Apply a constant rate of load to the specimen. Pros: More precise than CRE machines. Cons: More complex and expensive.

- Dynamic mechanical analyzers (DMAs): Apply a sinusoidal load to the specimen. Pros: Can measure viscoelastic properties. Cons: More complex and expensive than other testing machines.

4. How do you interpret the results of a tensile test on rubber?

Answer:

- Tensile strength: Indicates the strength of the rubber material in tension.

- Elongation at break: Indicates the ductility of the rubber material.

- Stress-strain curve: Provides information about the elastic and plastic behavior of the rubber material.

5. What are the different factors that can affect the results of a rubber testing method?

Answer:

- Specimen preparation: The size, shape, and condition of the specimen can affect the test results.

- Testing environment: The temperature, humidity, and other environmental factors can affect the test results.

- Testing equipment: The type and calibration of the testing equipment can affect the test results.

- Testing procedure: The speed of testing, the load applied, and other factors can affect the test results.

6. How do you ensure the accuracy and reliability of rubber testing results?

Answer:

- Proper specimen preparation: Follow the specified procedures for cutting and preparing the specimen.

- Controlled testing environment: Conduct the test in a controlled environment to minimize the effects of temperature, humidity, and other factors.

- Calibrated testing equipment: Use calibrated testing equipment and follow the manufacturer’s instructions for operation and maintenance.

- Standard testing procedures: Follow the established standard testing procedures to ensure consistency and accuracy.

- Data analysis: Analyze the test data carefully and follow statistical methods to ensure the reliability of the results.

7. What are the latest developments and trends in rubber testing?

Answer:

- Non-destructive testing: Techniques such as ultrasonic testing and infrared thermography are being used to test rubber without damaging the specimen.

- Accelerated testing: Methods are being developed to simulate the effects of long-term exposure on rubber in a shorter time frame.

- Automated testing: Automated testing systems are being used to improve efficiency and quality control in rubber testing.

8. What are the challenges in rubber testing and how do you overcome them?

Answer:

- Sample variability: Rubber is a heterogeneous material, which can lead to variability in test results. To overcome this, multiple samples are often tested and statistical methods are used to ensure the reliability of the results.

- Environmental effects: Temperature, humidity, and other environmental factors can affect the results of rubber testing. To overcome this, controlled testing environments are used and temperature-compensating equipment is employed.

- Complex behavior of rubber: Rubber is a viscoelastic material, which means that it exhibits both elastic and viscous behavior. To overcome this, specialized testing techniques are used to capture the complex behavior of rubber.

9. How do you keep up with the latest advances in rubber testing?

Answer:

- Attend industry conferences and symposia: Stay informed about the latest developments in rubber testing by attending industry conferences and symposia.

- Read technical journals and publications: Read technical journals and publications to stay abreast of the latest research and advancements in rubber testing.

- Participate in professional organizations: Join professional organizations such as the American Society for Testing and Materials (ASTM) to network with other professionals in the field and learn about the latest developments.

10. What are your strengths and weaknesses as a Rubber Tester?

Answer:

Strengths:- Strong technical skills and knowledge of rubber testing methods.

- Experience in operating and maintaining rubber testing equipment.

- Ability to analyze and interpret test results.

- Good problem-solving skills.

- Strong attention to detail and accuracy.

- Limited experience in non-destructive testing techniques.

- Need to improve proficiency in using statistical analysis software.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rubber Tester is accountable for executing a spectrum of tests and evaluations on various rubber products to ascertain their conformity to industry standards and customer specifications.

1. Rubber Testing and Evaluation

Perform a comprehensive range of tests on rubber products, including tensile strength, elongation, hardness, resilience, and other relevant properties.

- Utilize specialized equipment and techniques to conduct accurate and reliable testing.

- Prepare test specimens and adhere to established testing protocols.

2. Data Analysis and Interpretation

Analyze and interpret test results to determine the performance characteristics and quality of rubber products.

- Compare test results to industry standards and customer specifications to identify any deviations.

- Prepare comprehensive test reports summarizing the findings and recommendations.

3. Quality Control and Assurance

Contribute to the quality control and assurance processes by identifying and addressing any defects or inconsistencies in rubber products.

- Work closely with production teams to implement corrective actions to improve product quality.

- Maintain detailed records of all testing activities and results.

4. Research and Development

Participate in research and development projects to improve testing methods and advance the understanding of rubber properties.

- Explore new testing techniques and technologies to enhance the efficiency and accuracy of testing.

- Collaborate with engineers and scientists to develop innovative rubber products.

Interview Tips

To ace an interview for a Rubber Tester position, it is crucial to showcase your technical expertise, analytical skills, and attention to detail.

1. Research the Company and Industry

Thoroughly research the company you are applying to, including their products, industry standing, and recent developments.

- Demonstrate your understanding of the rubber industry and the specific testing requirements for their products.

2. Highlight Your Technical Proficiency

Emphasize your proficiency in rubber testing methods, including tensile strength testing, hardness testing, and resilience testing.

- Discuss your experience with specific testing equipment and techniques.

- Quantify your accomplishments by providing concrete examples of how your testing skills have contributed to improving product quality or research projects.

3. Showcase Your Analytical Abilities

Demonstrate your ability to analyze and interpret test results, identify trends, and draw meaningful conclusions.

- Provide examples of how you have used data analysis to identify product defects or optimize testing methods.

4. Emphasize Quality Control and Assurance

Highlight your commitment to quality control and assurance by describing your experience in identifying and addressing product defects.

- Discuss your understanding of quality standards, such as ISO or ASTM, and how you apply them in your work.

5. Prepare for Technical Questions

Anticipate technical questions related to rubber testing, such as:

- “Describe the different types of tensile strength tests and how they are used to evaluate rubber products.”

- “What factors can influence the hardness of a rubber compound?”

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Rubber Tester, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Rubber Tester positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.