Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Rubber Vulcanizing Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Rubber Vulcanizing Machine Operator so you can tailor your answers to impress potential employers.

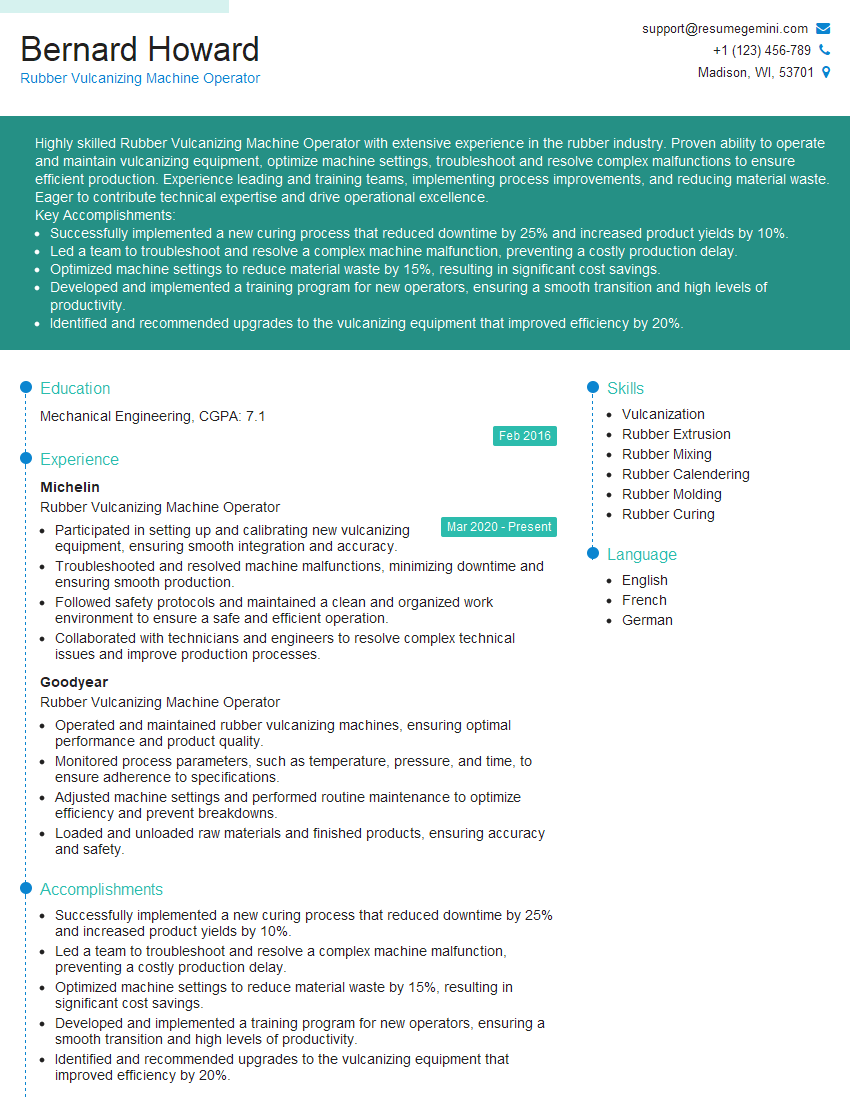

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rubber Vulcanizing Machine Operator

1. Describe the process of rubber vulcanization?

Rubber vulcanization is a chemical process that involves heating raw rubber with sulfur or other vulcanizing agents. This process results in the formation of cross-links between the rubber molecules, which improves the strength, durability, and elasticity of the rubber.

2. What are the key parameters that need to be controlled during rubber vulcanization?

Temperature

- Temperature plays a crucial role in determining the rate and extent of vulcanization.

- Variations in temperature can affect the properties of the final product, such as its strength and elasticity.

Time

- The duration of vulcanization is another important parameter that needs to be controlled.

- Insufficient vulcanization can lead to weak and brittle rubber, while excessive vulcanization can result in over-cured rubber with reduced elasticity.

Pressure

- Pressure can affect the density and uniformity of the vulcanized rubber.

- Proper pressure ensures that the rubber is evenly cured and free from voids or defects.

3. What are the different types of vulcanization methods?

- Hot vulcanization: This method involves heating the rubber mixture under pressure in a mold or press.

- Cold vulcanization: This method uses chemical cross-linking agents at room temperature, without the application of heat or pressure.

- Microwave vulcanization: This method employs microwave radiation to heat and vulcanize the rubber mixture.

4. How do you ensure the quality of vulcanized rubber products?

- By adhering to established quality control procedures and specifications.

- Performing regular inspections and testing of the raw materials, vulcanization process, and finished products.

- Maintaining accurate records and documentation to ensure traceability and compliance.

5. What are the common problems that can occur during rubber vulcanization and how do you troubleshoot them?

- Under-vulcanization: This can result in weak and brittle rubber. The solution is to increase the vulcanization time or temperature.

- Over-vulcanization: This can lead to hard and inflexible rubber. The solution is to reduce the vulcanization time or temperature.

- Scorching: This occurs when the rubber is exposed to excessive heat during vulcanization. The solution is to adjust the vulcanization parameters or use a scorch retarder in the rubber compound.

6. What is the role of accelerators and retarders in rubber vulcanization?

Accelerators

- Accelerators are chemicals that speed up the vulcanization reaction.

- They reduce the vulcanization time and improve the efficiency of the process.

Retarders

- Retarders are chemicals that slow down the vulcanization reaction.

- They prevent premature vulcanization and allow for better control over the process.

7. What safety precautions should be taken while operating a rubber vulcanizing machine?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Follow proper machine operating procedures and adhere to safety guidelines.

- Be aware of potential hazards, such as hot surfaces, moving parts, and chemical vapors.

8. How do you maintain a rubber vulcanizing machine?

- Regular cleaning and inspection of the machine and its components.

- Lubrication of moving parts as per the manufacturer’s recommendations.

- Calibration and adjustment of control systems.

9. What are the key troubleshooting steps for a rubber vulcanizing machine?

- Identify the problem and its potential causes.

- Check the machine settings, temperature, and pressure.

- Inspect the rubber compound and ensure it meets specifications.

- Consult with the manufacturer or technical experts for guidance.

10. How do you stay updated on the latest advancements and best practices in rubber vulcanization?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Participate in online forums and discussions.

- Consult with experts and research institutions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rubber Vulcanizing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rubber Vulcanizing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Rubber Vulcanizing Machine Operator is responsible for operating and maintaining rubber vulcanizing machines, ensuring the proper vulcanization of rubber products and maintaining a safe and productive work environment. Key job responsibilities include:

1. Machine Operation

Loading and unloading the vulcanizing machine with rubber molds and products

- Monitoring machine settings, such as temperature, pressure, and time

- Adjusting machine parameters to achieve optimal vulcanization results

2. Product Quality Control

Inspecting rubber products for defects and ensuring they meet quality standards

- Performing tests to verify product properties, such as hardness, tensile strength, and elasticity

- Identifying and rectifying any production issues that may arise

3. Machine Maintenance

Performing routine maintenance and repairs on vulcanizing machines

- Cleaning, lubricating, and adjusting machine components

- Troubleshooting and resolving mechanical issues

4. Safety and Compliance

Adhering to established safety protocols and regulations

- Wearing appropriate safety gear and maintaining a clean work area

- Following proper handling and storage procedures for hazardous materials

Interview Tips

To ace an interview for a Rubber Vulcanizing Machine Operator position, candidates can follow these valuable tips:

1. Research the Company and Industry

Demonstrate knowledge of the company’s business, products, and industry trends.

- Visit the company website and social media pages.

- Read industry-related articles and publications.

2. Highlight Relevant Experience and Skills

Emphasize your hands-on experience operating and maintaining rubber vulcanizing machines.

- Describe your expertise in quality control and product testing.

- Showcase your ability to troubleshoot and resolve mechanical issues.

3. Practice Answering Common Interview Questions

Prepare thoughtful responses to frequently asked interview questions, such as:

- “Tell me about your experience operating rubber vulcanizing machines.”

- “How do you ensure the quality of rubber products?”

- “What steps do you take to maintain and troubleshoot vulcanizing machines?”

4. Ask Insightful Questions

Engaging in meaningful dialogue shows interest and curiosity.

- Inquire about the company’s approach to product innovation.

- Ask about opportunities for professional development and growth.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately and punctuality demonstrates respect for the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rubber Vulcanizing Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.