Feeling lost in a sea of interview questions? Landed that dream interview for Ruffling Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ruffling Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

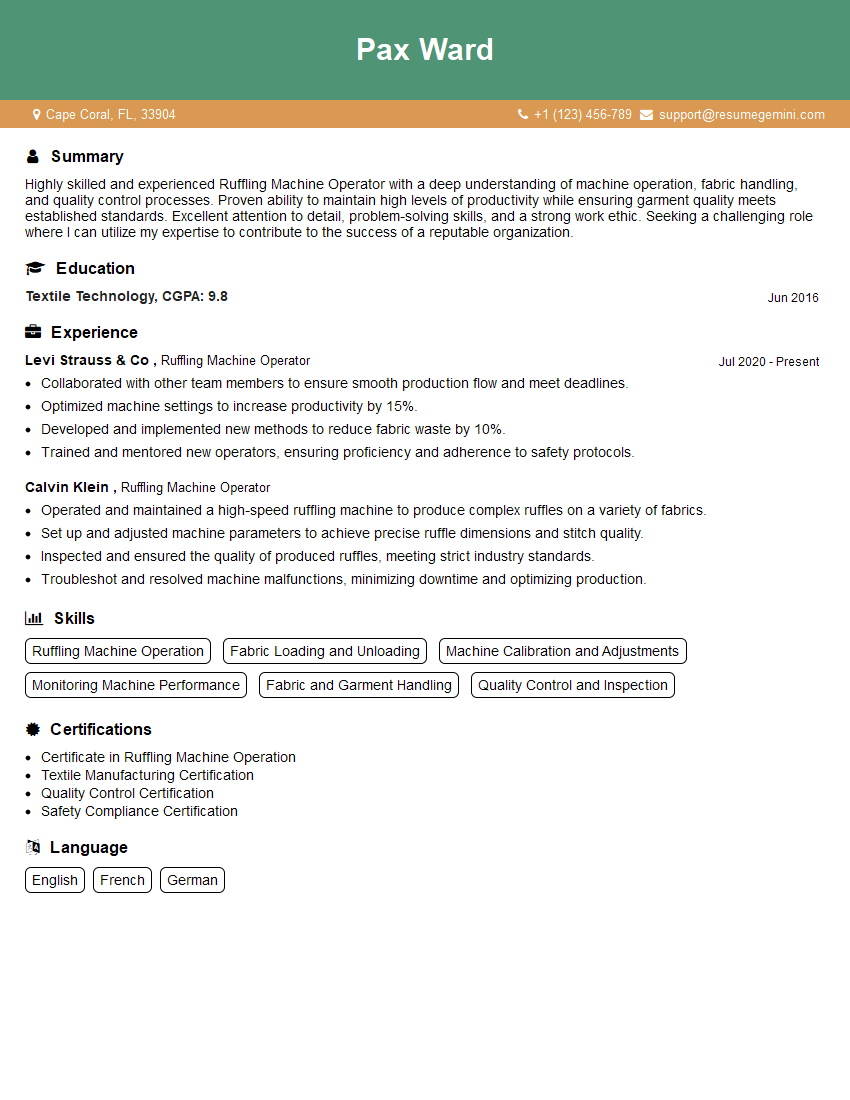

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ruffling Machine Operator

1. Describe the main responsibilities of a Ruffling Machine Operator?

As a Ruffling Machine Operator, my primary responsibilities include:

- Setting up and operating the ruffling machine to create gathers and ruffles in fabrics

- Maintaining the machine, ensuring its proper functioning, and troubleshooting any issues that arise

- Inspecting the produced fabrics to ensure they meet quality standards and specifications

- Adhering to safety protocols and maintaining a clean and organized work area

- Following instructions from supervisors and collaborating with other operators to meet production targets

2. Explain the different types of ruffling machines and their applications?

Mechanical Ruffling Machine

- Uses mechanical components to create gathers and ruffles

- Suitable for heavy-duty fabrics and large-scale production

Pneumatic Ruffling Machine

- Employs pneumatic pressure to generate ruffles

- Provides precise control over the ruffling process and is ideal for delicate fabrics

Ultrasonic Ruffling Machine

- Utilizes ultrasonic waves to create ruffles without sewing or stitching

- Produces clean and seamless ruffles, suitable for delicate and synthetic fabrics

3. Describe the key factors that affect the quality of ruffles?

The quality of ruffles is influenced by several factors, including:

- Fabric type: Different fabrics have varying properties that affect the ruffling process

- Machine settings: Proper tension, speed, and stitch length are crucial for consistent ruffles

- Operator skills: Experience and attention to detail ensure high-quality output

- Maintenance: Regular cleaning and lubrication of the machine prevent breakdowns and ensure smooth operation

- Environmental conditions: Temperature and humidity can affect the performance of the machine and the quality of ruffles

4. How do you troubleshoot common problems that may arise with a ruffling machine?

Common problems and their troubleshooting steps include:

- Skipped stitches: Check the needle, thread tension, and fabric thickness

- Broken thread: Inspect the thread path for obstructions or damage

- Uneven ruffles: Adjust machine settings such as tension or stitch length

- Puckering or distortion: Ensure the fabric is flat and free of wrinkles

- Machine overheating: Allow the machine to cool down and check for any blockages in the airflow

5. Explain the importance of quality control in the ruffling process?

Quality control is essential in the ruffling process to:

- Ensure that the ruffles meet the desired specifications and customer requirements

- Identify and rectify defects early in the production process, minimizing waste

- Maintain a consistent level of quality throughout the production run

- Enhance customer satisfaction and build a reputation for delivering high-quality products

- Comply with industry standards and regulations

6. Describe how you prioritize tasks and manage your time effectively?

To prioritize tasks and manage my time effectively, I:

- Assess the urgency and importance of each task

- Create a daily or weekly to-do list and set deadlines

- Break down large tasks into smaller, manageable steps

- Delegate tasks when appropriate

- Use time management techniques such as the Pomodoro method

- Avoid distractions and minimize multitasking

7. How do you handle working under pressure and meeting tight deadlines?

When working under pressure and meeting tight deadlines, I:

- Stay calm and focused on the task at hand

- Prioritize tasks and allocate my time wisely

- Communicate with my supervisor or colleagues if additional support is needed

- Take short breaks to clear my head and maintain productivity

- Avoid procrastination and start working on tasks promptly

8. Describe a challenging situation you faced as a Ruffling Machine Operator and how you overcame it?

In a previous role, I encountered a situation where the ruffling machine malfunctioned during a large production run. I quickly identified the problem as a faulty sensor. However, the replacement part was not readily available. To overcome this challenge, I worked with a colleague to develop a temporary solution using alternative components. This allowed us to complete the production run on time with minimal disruption.

9. How do you stay updated with the latest advances in ruffling technology?

To stay updated with the latest advances in ruffling technology, I:

- Attend industry conferences and workshops

- Read trade publications and technical articles

- Consult with machinery manufacturers and suppliers

- Network with other Ruffling Machine Operators and professionals in the field

- Conduct research and explore new techniques and advancements

10. Why are you interested in working as a Ruffling Machine Operator in our company?

I am eager to join your company as a Ruffling Machine Operator because:

- Your company is a reputable leader in the industry, known for its commitment to quality and innovation.

- The opportunity to work with state-of-the-art ruffling equipment and experienced professionals excites me.

- I believe my skills and experience would be a valuable asset to your team, and I am confident that I can contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ruffling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ruffling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ruffling Machine Operators are responsible for operating a ruffling machine to create pleats and gathers in fabric. They must be able to follow instructions, set up the machine, and troubleshoot any problems that may arise.

1. Set up and operate the ruffling machine

This involves loading the fabric into the machine, adjusting the tension and speed settings, and starting the machine.

- Load fabric onto the machine’s conveyor belt.

- Adjust tension and speed settings according to fabric type and desired results.

- Start the machine and monitor its operation.

2. Monitor the ruffling process

The operator must watch the fabric as it passes through the machine to ensure that the pleats and gathers are being created correctly. They must also check for any problems, such as fabric jams or tears.

- Observe fabric as it passes through the machine, ensuring pleats and gathers are created as desired.

- Monitor machine for any issues, such as fabric jams or tears.

- Stop the machine promptly if any problems occur.

3. Make adjustments to the machine

The operator may need to make adjustments to the machine to ensure that the pleats and gathers are being created correctly. This may involve adjusting the tension or speed settings, or changing the position of the fabric.

- Adjust tension or speed settings to achieve desired pleating or gathering effect.

- Reposition fabric on the conveyor belt if necessary to ensure proper pleating or gathering.

- Calibrate the machine regularly to maintain accuracy and precision.

4. Clean and maintain the machine

The operator must clean and maintain the machine to ensure that it is running properly. This may involve cleaning the fabric path, oiling the moving parts, and checking the tension settings.

- Clean fabric path to remove any lint or debris that could affect machine operation.

- Oil moving parts periodically to reduce wear and tear.

- Check tension settings regularly to ensure proper pleating or gathering.

Interview Tips

Preparing for a job interview can be daunting, but it’s crucial to put in the effort to increase your chances of success. Here are a few tips to help you ace your Ruffling Machine Operator interview:

1. Research the company and the position

Take some time to learn about the company you’re applying to and the specific role you’re interviewing for. This will help you answer questions intelligently and show that you’re genuinely interested in the opportunity.

- Visit the company’s website to learn about their history, products, and services.

- Read industry news and articles to stay up-to-date on the latest trends.

- Check out the company’s social media pages to get a sense of their culture and values.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Prepare a brief introduction that highlights your relevant skills and experience.

- Think about why you’re interested in the position and what you can bring to the company.

- Be prepared to discuss your strengths and weaknesses.

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time to show that you’re respectful of the interviewer’s time.

- Choose clothing that is clean, pressed, and fits well.

- Avoid wearing clothing that is too revealing or casual.

- Plan your route to the interview location in advance so that you can avoid getting lost or being late.

4. Be enthusiastic and positive

Interviewers are more likely to be impressed by candidates who are enthusiastic and positive about the opportunity. Show that you’re excited about the possibility of working for the company and that you’re confident in your abilities.

- Smile and make eye contact with the interviewer.

- Be polite and respectful, even if you’re nervous.

- Speak clearly and confidently, and avoid using filler words such as “um” and “like.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ruffling Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!