Feeling lost in a sea of interview questions? Landed that dream interview for Ruling Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ruling Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

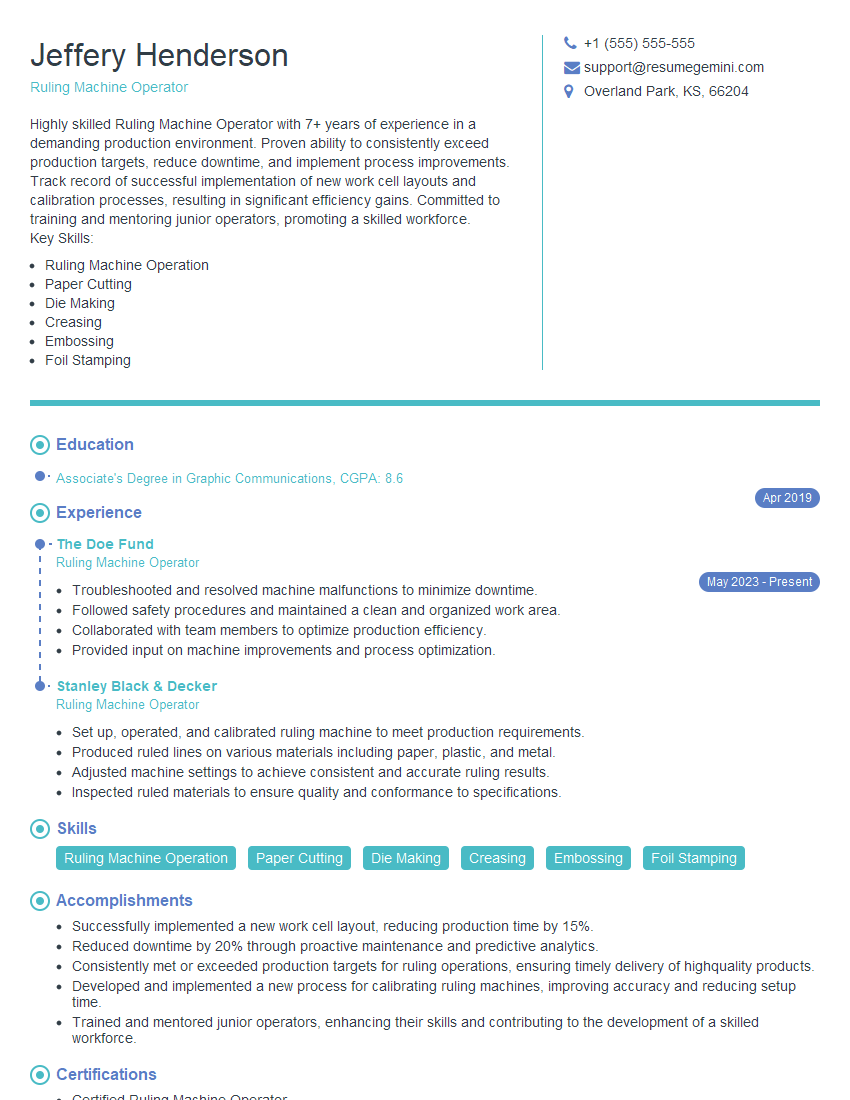

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ruling Machine Operator

1. Describe the process of setting up and operating a ruling machine.

The setup and operation of a ruling machine involve several steps:

- Machine Preparation: Ensure the machine is clean, lubricated, and has the appropriate tooling installed.

- Stock Loading: Load the material to be ruled into the machine’s feeder, ensuring proper alignment and tension.

- Ruling Parameters: Set the machine’s ruling parameters, including the spacing, depth, and angle of the lines.

- Calibration: Calibrate the machine using a calibrated ruler or other measuring device to ensure accurate rulings.

2. How do you troubleshoot common problems encountered while operating a ruling machine?

Identifying Problems:

- Uneven Ruling: Check for proper belt tension, alignment, or ruling tool wear.

- Skipped Lines: Inspect the feeder and material tension, or adjust the ruling tool depth.

- Poor Line Quality: Evaluate the sharpness of the ruling tool, material thickness, or machine vibration.

Troubleshooting:

- Adjust Parameters: Optimize ruling parameters such as speed, pressure, or line depth.

- Clean and Inspect: Remove debris from the feeder, ruling tools, and machine components.

- Replace Components: If necessary, replace worn or damaged parts, such as ruling tools or belts.

3. Explain the importance of maintaining proper tension during the ruling process.

Maintaining proper tension during ruling is crucial for several reasons:

- Accurate Lines: Proper tension ensures the material is held taut, reducing the risk of lines being skewed or distorted.

- Reduced Errors: Consistent tension prevents the material from slipping or stretching, minimizing errors in line spacing and angles.

- Machine Longevity: Correct tension reduces stress on the machine’s components, extending its lifespan.

- Efficient Operation: Optimal tension allows for faster and more efficient ruling, improving productivity.

4. Describe the different types of ruling patterns and their applications.

- Parallel Ruling: Straight lines running parallel to each other, used for invitations, letterheads, and forms.

- Cross Ruling: Parallel lines intersecting at right angles, creating a grid pattern for notebooks and graph paper.

- Angular Ruling: Lines intersecting at an angle, adding a decorative element to packaging or invitations.

- Decorative Ruling: Intricate patterns and designs, used for special occasions or high-end products.

5. How do you ensure the quality of rulings meets customer specifications?

- Sample Approval: Obtain client approval on a sample ruling before commencing production.

- Calibration and Inspection: Regularly calibrate the machine and inspect rulings using precision measuring tools.

- Documentation: Maintain records of machine settings, ruling parameters, and inspection results for traceability.

- Customer Feedback: Seek customer feedback and address any concerns or quality issues promptly.

6. Explain how you handle high-volume ruling orders while maintaining accuracy and efficiency.

- Optimized Scheduling: Plan production schedules to minimize downtime and ensure timely delivery.

- Preventive Maintenance: Regularly maintain the machine to prevent breakdowns and ensure uninterrupted operation.

- Automation: Utilize automated feeders and other tools to improve efficiency and reduce manual errors.

- Teamwork and Communication: Collaborate with team members to ensure proper material handling and quality control.

7. What safety precautions are essential when operating a ruling machine?

- Machine Guarding: Ensure all moving parts are guarded to prevent contact and accidents.

- Protective Gear: Wear appropriate safety gear, such as gloves and safety glasses.

- Electrical Safety: Follow proper lockout procedures and ensure electrical connections are secure.

- Emergency Stops: Be familiar with the location and operation of emergency stop buttons.

- Material Handling: Use proper techniques for lifting and moving heavy materials.

8. Describe the different types of ruling tools used and their advantages and disadvantages.

- Steel Blades: Durable and precise but require regular sharpening and are not suitable for soft materials.

- Diamond-Tipped Blades: Extremely sharp and long-lasting, suitable for hard and abrasive materials but can be expensive.

- Ceramic Blades: Corrosion-resistant and provide a clean cut, ideal for delicate materials but can be fragile.

- Engraved Rollers: Create continuous patterns, suitable for high-volume production but limited in design flexibility.

9. Explain how you calculate the ruling parameters for different materials and ruling patterns.

- Material Properties: Consider the thickness, hardness, and grain direction of the material.

- Ruling Pattern: Determine the spacing, depth, and angle of the lines to achieve the desired effect.

- Ruling Machine Capabilities: Ensure the machine can accommodate the required parameters.

- Experimental Trials: Conduct small-scale tests to optimize parameters and ensure satisfactory results.

10. Describe your experience in maintaining and repairing ruling machines.

- Regular Maintenance: Lubrication, cleaning, and adjustment of components to prevent breakdowns.

- Troubleshooting: Diagnosing and resolving malfunctions, such as uneven ruling or skipped lines.

- Repair and Replacement: Replacing worn or damaged parts, such as belts, bearings, and ruling tools.

- Calibration and Alignment: Ensuring the machine’s accuracy and precision through regular calibration and alignment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ruling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ruling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Ruling Machine Operator is a skilled professional responsible for operating and maintaining ruling machines, which are used to create precise lines and patterns on paper, cardboard, and other materials. Their primary responsibilities include:

1. Machine Operation

Operate ruling machines to create lines and patterns on various materials, such as paper, cardboard, and plastic.

- Set up and adjust ruling machines according to specifications.

- Load and feed materials into the machine.

- Monitor machine operations and make adjustments as needed.

2. Quality Control

Inspect ruled products to ensure they meet quality standards.

- Check for accuracy, precision, and consistency.

- Identify and correct any defects or errors.

- Maintain records of inspection results.

3. Maintenance and Troubleshooting

Perform preventive maintenance and troubleshoot machine malfunctions.

- Clean and lubricate machine components.

- Identify and replace worn or damaged parts.

- Resolve operational issues and ensure smooth machine operation.

4. Safety and Compliance

Adhere to safety regulations and ensure a safe working environment.

- Follow safety procedures for machine operation.

- Maintain a clean and organized work area.

- Report any safety concerns or hazards.

Interview Tips

To ace an interview for a Ruling Machine Operator position, follow these tips:

1. Research the Company and Position

Thoroughly research the company and the specific role to gain insights into their industry, values, and expectations.

- Visit the company website to learn about their products, services, and culture.

- Review the job description carefully to understand the key responsibilities and qualifications.

2. Highlight Relevant Skills and Experience

Showcase your skills and experience that are directly relevant to the role of a Ruling Machine Operator.

- Emphasize your proficiency in operating ruling machines and your ability to produce high-quality ruled products.

- Demonstrate your attention to detail, accuracy, and problem-solving abilities.

3. Prepare for Technical Questions

Expect to answer technical questions related to ruling machine operation and maintenance.

- Review the basics of ruling machines, including their components and functionality.

- Be familiar with common troubleshooting techniques and maintenance procedures.

4. Show Enthusiasm and Professionalism

Convey your enthusiasm for the role and demonstrate your professionalism throughout the interview.

- Dress appropriately and arrive on time.

- Maintain eye contact, speak clearly, and listen attentively.

- Ask thoughtful questions to show your interest and engagement.

Next Step:

Now that you’re armed with the knowledge of Ruling Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Ruling Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini