Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ruling Machine Set-Up Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

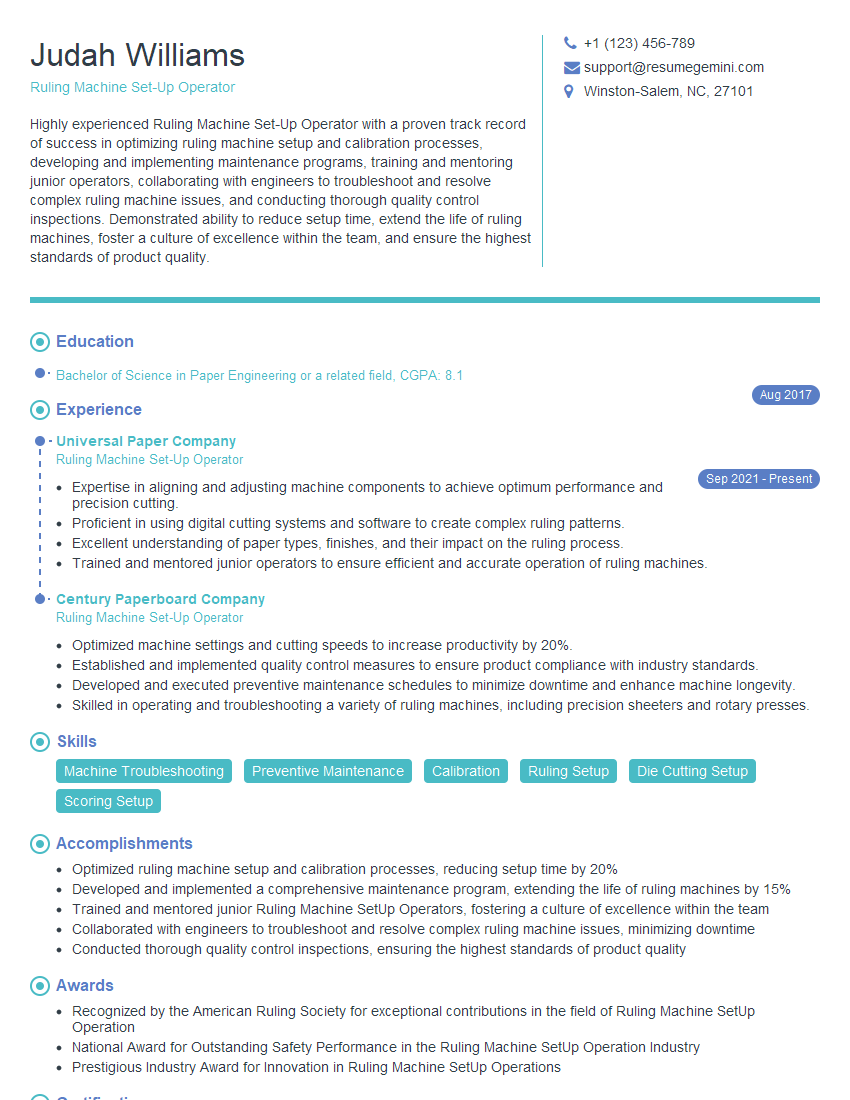

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ruling Machine Set-Up Operator

1. What are the key responsibilities of a Ruling Machine Set-Up Operator?

As a Ruling Machine Set-Up Operator, my primary responsibilities include:

- Setting up and calibrating ruling machines to meet production specifications

- Loading and unloading paper and other materials into the ruling machine

- Monitoring the ruling process to ensure quality and accuracy

- Maintaining and troubleshooting ruling machines to prevent breakdowns and ensure optimal performance

- Working closely with other production personnel to ensure smooth operations

2. How do you ensure accurate and consistent ruling on different types of paper?

Ensuring accurate and consistent ruling on different types of paper requires a combination of machine calibration, material selection, and operator skill:

Paper Selection:

- Selecting the appropriate paper grade and thickness for the desired ruling pattern

- Verifying paper quality to avoid defects that can affect ruling accuracy

Machine Calibration:

- Fine-tuning ruling machine settings to match paper specifications

- Adjusting ruling depth, spacing, and other parameters to achieve optimal results

Operator Skill:

- Properly loading paper into the machine to ensure precise alignment

- Monitoring the ruling process and making adjustments as needed to maintain consistency

3. What steps do you take to troubleshoot common ruling machine problems?

To troubleshoot common ruling machine problems, I follow a systematic approach:

- Identifying the problem and gathering information about its symptoms

- Checking the machine’s settings and comparing them to specifications

- Inspecting the paper, rollers, and other components for damage or wear

- Running test batches to isolate the issue and determine the root cause

- Implementing corrective actions, such as adjusting settings, replacing parts, or recalibrating the machine

4. How do you measure and maintain ruling quality?

Maintaining ruling quality involves:

- Using precision measuring tools to verify ruling accuracy, such as calipers or microscopes

- Inspecting ruled materials for defects, such as skipped lines, uneven spacing, or smudging

- Developing quality control standards and implementing inspection procedures

- Regularly calibrating ruling machines and replacing worn or damaged parts

- Continuously monitoring the ruling process and making adjustments as needed to maintain optimal performance

5. Describe your experience in working with different types of ruling patterns.

Throughout my career, I have worked with a wide range of ruling patterns, including:

- Horizontal and vertical lines

- Grid patterns

- Complex geometric patterns

- Security patterns for checks and banknotes

- Decorative patterns for packaging and stationery

My experience in handling these diverse patterns has equipped me with the versatility and expertise to meet the demands of various production requirements.

6. What safety precautions do you take when operating a ruling machine?

Safety is paramount when operating a ruling machine:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses and gloves

- Ensuring the machine is properly grounded and electrically safe

- Inspecting the machine before each use for potential hazards

- Maintaining a clean and organized work area to prevent tripping or falling

- Following established safety protocols and reporting any unsafe conditions immediately

7. What techniques do you use to minimize waste and optimize material usage?

Minimizing waste and optimizing material usage are crucial in my role:

- Accurately calculating paper requirements based on ruling patterns and machine capabilities

- Utilizing scrap materials for test runs and small-scale projects

- Implementing efficient loading techniques to avoid paper jams and damage

- Regularly cleaning and maintaining the machine to reduce downtime and material wastage

- Collaborating with other departments to explore alternative materials or recycling options

8. How do you stay up-to-date with the latest advancements in ruling technology?

To stay current with industry trends and technological advancements, I:

- Attend industry conferences and exhibitions

- Read trade publications and technical journals

- Participate in online forums and webinars

- Seek training opportunities from manufacturers and industry experts

- Collaborate with colleagues and share knowledge to enhance collective expertise

9. Can you describe a time when you had to overcome a challenging situation in your role as a Ruling Machine Set-Up Operator?

In a previous role, we encountered an issue with consistent ruling depth on a particular job:

- I thoroughly inspected the machine and paper, but could not identify any immediate problems

- I consulted with a senior technician and together we devised a plan to test different settings and materials

- After several iterations, we discovered that a subtle variation in the paper tension was causing the inconsistent ruling depth

- By making precise adjustments to the tension settings, we resolved the issue and successfully completed the job on time

10. Why are you interested in this position at our company?

I am eager to join your company as a Ruling Machine Set-Up Operator due to:

- Your reputation as a leader in the industry with a commitment to quality and innovation

- The opportunity to work with state-of-the-art ruling technology and contribute to the production of high-quality products

- The prospect of collaborating with a team of experienced professionals in a dynamic work environment

- The company’s strong focus on employee growth and development

- The opportunity to make a meaningful contribution to your ongoing success

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ruling Machine Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ruling Machine Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ruling Machine Set-Up Operators are responsible for setting up and operating ruling machines used in the printing industry. They work closely with prepress and pressroom personnel to ensure that the ruling is accurate and meets customer specifications.

1. Machine Setup

Ruling Machine Set-Up Operators are responsible for setting up the ruling machine according to the job specifications. This includes:

- Installing and adjusting the ruling dies

- Setting the machine speed and feed rate

- Adjusting the ink and water levels

2. Machine Operation

Once the machine is set up, the operator is responsible for running the machine and monitoring the quality of the output. This includes:

- Feeding the paper into the machine

- Monitoring the machine for any problems

- Making adjustments to the machine as needed

3. Troubleshooting

Ruling Machine Set-Up Operators are also responsible for troubleshooting any problems that may occur with the machine. This includes:

- Identifying the source of the problem

- Making repairs or adjustments to the machine

- Restarting the machine and ensuring that it is running properly

4. Quality Control

Ruling Machine Set-Up Operators are responsible for ensuring that the quality of the ruling meets customer specifications. This includes:

- Inspecting the ruled paper for defects

- Making adjustments to the machine as needed

- Reporting any quality problems to the supervisor

Interview Tips

To ace the interview for a Ruling Machine Set-Up Operator position, it is important to be prepared to answer questions about your experience and qualifications. Here are a few tips to help you prepare:

1. Practice answering common interview questions

Some common interview questions that you may be asked include:

- Tell me about your experience setting up and operating ruling machines.

- What are some of the challenges you have faced as a Ruling Machine Set-Up Operator?

- How do you ensure that the quality of the ruling meets customer specifications?

2. Be prepared to talk about your troubleshooting skills

As a Ruling Machine Set-Up Operator, you may be asked to troubleshoot problems with the machine. Be prepared to discuss your troubleshooting skills and provide examples of how you have solved problems in the past.

3. Be prepared to answer questions about your knowledge of the printing industry

Ruling Machine Set-Up Operators should have a basic understanding of the printing industry. Be prepared to answer questions about different types of printing processes and how ruling is used in the printing process.

4. Be prepared to show your work

If possible, bring examples of your work to the interview. This could include samples of ruled paper or photos of machines that you have set up. This will show the interviewer that you are proud of your work and that you are confident in your abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ruling Machine Set-Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!