Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Rum Processing Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

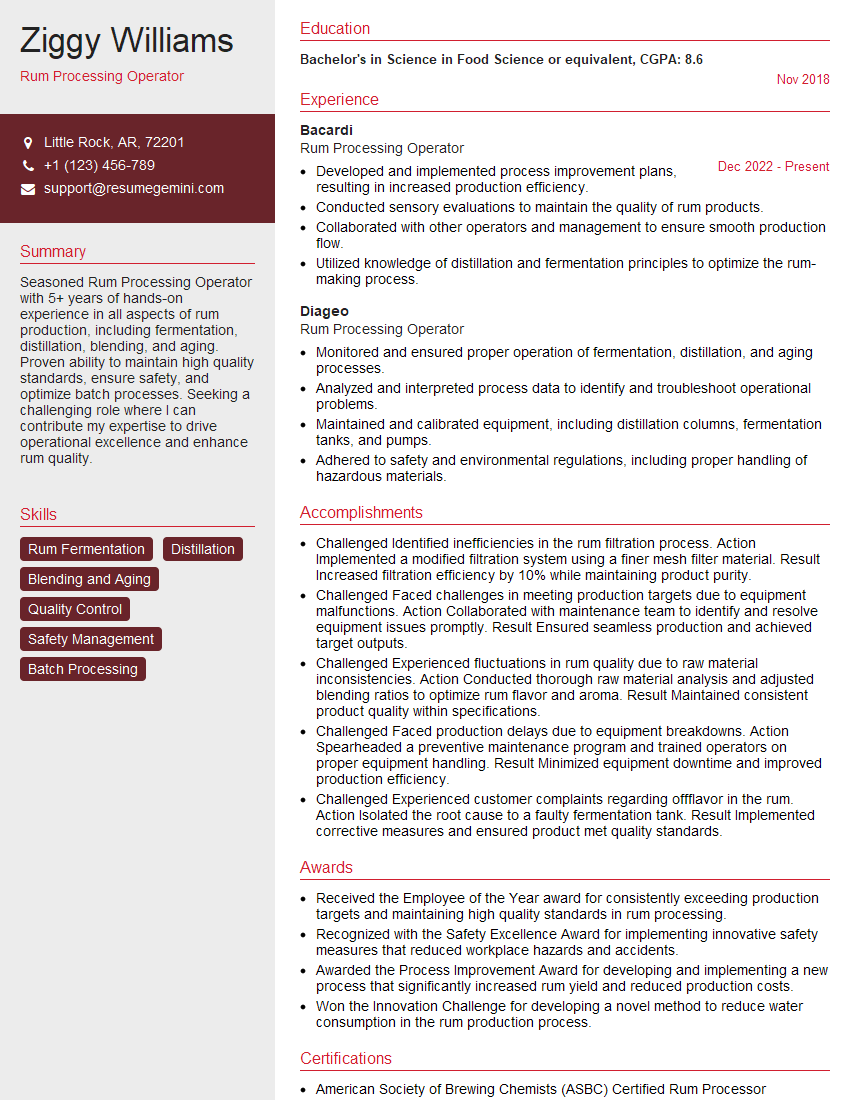

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rum Processing Operator

1. Explain the process of fermentation in rum production?

Fermentation is a crucial step in rum production where yeast converts sugar into alcohol. The process involves:

- Preparing a fermentation mash: This involves mixing molasses, water, and yeast in a fermentation tank.

- Maintaining optimal fermentation conditions: Temperature, pH, and Brix levels are closely monitored and adjusted to ensure optimal yeast activity.

- Aerating the mash: Oxygen is supplied to the yeast to facilitate cell growth and efficient fermentation.

- Controlling fermentation rate: The fermentation period can vary depending on the desired alcohol content and flavor profile of the rum.

2. Describe the role of distillation in rum production and its different methods.

Batch Distillation

- Involves filling a still with fermented mash and heating it to vaporize the alcohol and other volatile compounds.

- The vapor is then condensed back into a liquid, resulting in a higher alcohol content.

Continuous Distillation

- A more efficient method where the mash is continuously fed into the still and vaporized.

- The vapor passes through a series of trays or columns, allowing for multiple distillations in one process.

3. How do you maintain the quality of rum during aging?

- Selecting suitable barrels: Oak barrels are typically used for aging rum, as they impart flavors and aromas.

- Controlling temperature and humidity: The storage environment plays a crucial role in the aging process, affecting the evaporation rate and flavor development.

- Monitoring barrel fill levels: Ensuring that barrels are filled to the proper level prevents excessive oxidation and maintains the quality of the rum.

- Regular tasting and blending: Periodically tasting the rum allows for assessing its progress and making necessary adjustments in the aging process.

4. Discuss the various filtration techniques used in rum production and their impact on the final product.

- Carbon Filtration: Removes impurities and color, resulting in a clear and smooth rum.

- Membrane Filtration: Utilizes membranes to filter out particles and microorganisms, producing a sterile and consistent rum.

- Chill Filtration: Cools the rum to precipitate solids, resulting in a more polished and clear appearance.

- Filtration Impact: Filtration techniques can alter the flavor, aroma, and color of the rum, influencing its overall character.

5. Explain the different ways to package and store rum to preserve its quality and flavor.

- Bottling: Rum is typically bottled in glass or ceramic containers to protect it from light and air.

- Barrel Aging: Some rums are aged in oak barrels after bottling to further enhance their flavor and complexity.

- Storage: Rum should be stored in a cool, dark place to prevent deterioration and preserve its quality over time.

- Proper Sealing: Bottles and barrels should be properly sealed to prevent oxidation and evaporation.

6. How do you identify and manage potential hazards and safety concerns in a rum processing facility?

- Hazard Identification: Conduct regular risk assessments to identify potential hazards such as chemical spills, fires, and explosions.

- Control Measures: Implement appropriate control measures such as proper ventilation, safe handling procedures, and personal protective equipment.

- Emergency Response: Establish clear emergency response plans and train employees on how to handle potential incidents.

- Safety Culture: Foster a positive safety culture where employees are encouraged to report any concerns or near-misses.

7. What are the different types of additives that can be used in rum production and their potential effects on the final product?

- Sugar: Can be added to adjust the sweetness and flavor profile.

- Caramel: Adds color and enhances the rum’s smoothness.

- Flavors: Natural or artificial flavors can be added to create unique flavor profiles.

- Additives Impact: The type and quantity of additives used can significantly influence the taste, aroma, and color of the final rum.

8. Describe the key quality control parameters in rum production and how you ensure compliance with industry standards.

- Alcohol Content: Measured using hydrometers or refractometers to ensure it meets regulatory requirements.

- pH Level: Monitored to control fermentation and maintain the desired flavor profile.

- Color: Assessed visually or using spectrophotometers to ensure consistency and meet customer specifications.

- Sensory Analysis: Regular tasting panels are conducted to evaluate the flavor, aroma, and overall quality of the rum.

9. Explain how you would troubleshoot and resolve common issues that may arise during rum processing.

- Slow Fermentation: Check yeast activity, temperature, and nutrient levels.

- Off-Flavors: Identify the source (e.g., contamination, improper distillation) and take corrective action.

- Excessive Oxidation: Ensure proper barrel storage, sealing, and oxygen management.

- Filtration Problems: Inspect filters, adjust flow rates, and check for blockages.

10. Describe the role of automation in rum processing and its benefits.

- Improved Efficiency: Automation streamlines processes, reducing labor costs and increasing production capacity.

- Enhanced Quality Control: Automated systems can monitor and maintain critical parameters more accurately.

- Reduced Human Error: Automation minimizes the risk of errors and maintains consistent product quality.

- Data Collection and Analysis: Automated systems collect data that can be analyzed to improve processes and optimize production.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rum Processing Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rum Processing Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Rum Processing Operator is responsible for the safe and efficient operation of the rum processing equipment. This includes monitoring the equipment, making adjustments as needed, and taking corrective action in the event of a problem. The Rum Processing Operator also performs daily cleaning and maintenance of the equipment.1. Monitor and Operate Processing Equipment

The Rum Processing Operator is responsible for monitoring and operating the rum processing equipment. This includes:

- Starting and stopping the equipment

- Adjusting the speed and temperature of the equipment

- Monitoring the flow of rum through the equipment

- Taking corrective action in the event of a problem

2. Perform Cleaning and Maintenance

The Rum Processing Operator is also responsible for performing daily cleaning and maintenance of the equipment. This includes:

- Cleaning the equipment with water and soap

- Lubricating the equipment

- Inspecting the equipment for damage

- Making minor repairs to the equipment

3. Maintain Work Area

The Rum Processing Operator is also responsible for maintaining the work area. This includes:

- Keeping the work area clean and organized

- Storing materials and equipment properly

- Disposing of waste materials properly

4. Other Duties

In addition to the above, the Rum Processing Operator may also be required to perform other duties, such as:

- Assisting other operators with their duties

- Training new operators

- Following safety procedures

Interview Tips

Preparing for an interview can be daunting, but by following these tips, you can increase your chances of success.1. Research the Company and Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you understand the specific requirements of the position and how your skills and experience match those requirements.

2. Practice Your Answers

One of the best ways to prepare for an interview is to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview. You can practice your answers with a friend, family member, or career counselor.

3. Be Yourself

It is important to be yourself during an interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and authentic, and let your personality shine through.

4. Ask Questions

Asking questions at the end of an interview shows that you are engaged and interested in the position. It is also a great way to learn more about the company and the position. Prepare a few questions to ask the interviewer beforehand.

5. Follow Up

After your interview, follow up with the interviewer by sending a thank-you note. This is a great way to express your appreciation for the interviewer’s time and to reiterate your interest in the position.

Next Step:

Now that you’re armed with the knowledge of Rum Processing Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Rum Processing Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini