Are you gearing up for an interview for a Rust Proofer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rust Proofer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

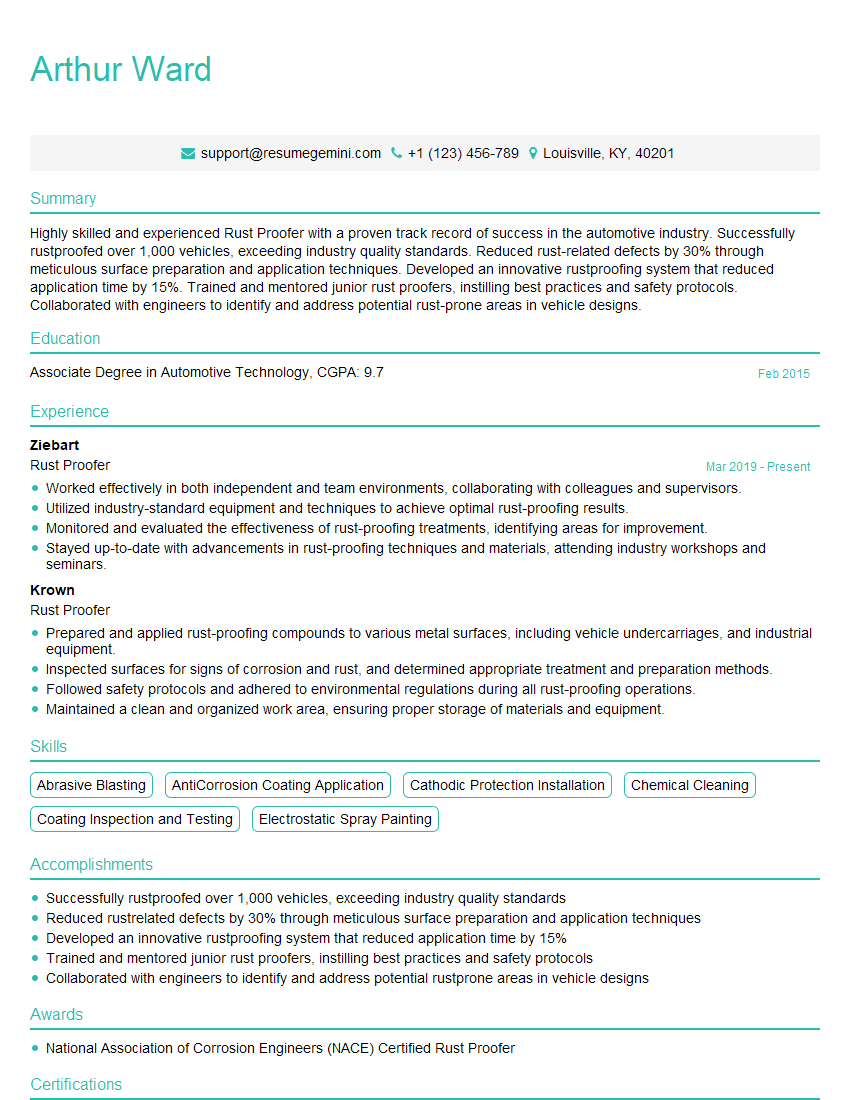

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rust Proofer

1. What are the different types of rust proofing methods?

- Electrostatic Spraying

- Dip Coating

- Brush-On Application

- Hot Dip Galvanizing

- Zinc Plating

2. What are the advantages and disadvantages of each rust proofing method?

Electrostatic Spraying

- Advantages: Uniform coating, high coverage, good adhesion

- Disadvantages: requires specialized equipment, can be expensive

Dip Coating

- Advantages: simple and cost-effective, provides thick coating

- Disadvantages: can be difficult to apply to complex shapes, requires dipping tank

Brush-On Application

- Advantages: easy to apply, no special equipment required

- Disadvantages: can result in uneven coating, requires multiple applications

Hot Dip Galvanizing

- Advantages: durable, long-lasting protection, corrosion-resistant

- Disadvantages: can be expensive, requires specialized equipment

Zinc Plating

- Advantages: provides sacrificial protection, cathodic protection

- Disadvantages: can be brittle, requires chemical baths

3. What is the best rust proofing method for a particular application?

The best rust proofing method depends on factors such as the type of metal, the environment, and the desired level of protection. Generally, for automotive applications, electrostatic spraying or dip coating are recommended. For industrial applications, hot dip galvanizing or zinc plating may be more suitable. For home projects, brush-on applications may be sufficient.

4. What are the safety precautions that should be taken when applying rust proofing products?

- Wear appropriate safety gear (gloves, goggles, respirator)

- Ensure proper ventilation

- Follow manufacturer’s instructions carefully

- Dispose of used materials properly

5. What is the importance of surface preparation before applying rust proofing products?

Surface preparation is crucial for effective rust proofing. It removes dirt, grease, and other contaminants that can interfere with adhesion. Proper surface preparation ensures that the rust proofing product can bond properly to the metal surface and provide long-lasting protection.

6. What are the common causes of rust and how can they be prevented?

- Exposure to moisture (water, humidity)

- Contact with oxygen

- Presence of electrolytes (salt, acids)

- Keep surfaces dry

- Apply rust proofing products

- Avoid exposure to harsh chemicals

- Galvanize or zinc plate metal surfaces

Causes of rust

Prevention methods

7. What are the signs of rust and how should they be addressed?

- Discoloration (brown, orange, red)

- Pitting (small holes)

- Flaking (peeling paint)

- Address by removing existing rust, preparing the surface, and applying rust proofing products

8. What are the different types of rust proofing equipment used by professionals?

- Electrostatic spray guns

- Dip tanks

- Airless sprayers

- Wire brushes

- Sandblasters

9. What are the latest advancements in rust proofing technology?

- Nanotechnology-based coatings

- Self-healing coatings

- Corrosion-resistant alloys

- Plasma electrolytic oxidation (PEO)

- Vapor-phase rust inhibitors

10. What are the qualities and skills required to be a successful rust proofer?

- Attention to detail

- Manual dexterity

- Knowledge of rust proofing methods and products

- Ability to follow instructions and safety protocols

- Physical stamina (standing/bending for extended periods)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rust Proofer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rust Proofer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rust Proofers are responsible for applying rust-resistant coatings to metal surfaces to prevent corrosion. They may also be involved in preparing surfaces for coating, such as cleaning, sanding, or grinding. Key job responsibilities include:

1. Surface Preparation

Ensuring that metal surfaces are clean, dry, and free of dirt, grease, or other contaminants

- Sanding or grinding to remove rust or old coatings

- Cleaning surfaces with solvents or chemicals

2. Coating Application

Applying rust-resistant coatings to prepared surfaces using spray guns, brushes, or rollers

- Ensuring even and consistent coverage

- Applying multiple coats as required

3. Drying and Curing

Allowing coatings to dry and cure according to manufacturer’s instructions

- Monitoring drying times and temperatures

- Ensuring proper ventilation during drying

4. Quality Control

Inspecting coated surfaces to ensure they meet quality standards

- Checking for defects, such as bubbles, runs, or thin spots

- Conducting adhesion tests

Interview Tips

To ace a Rust Proofer interview, it is important to be well-prepared. Here are some tips and hacks:

1. Research the Industry and Company

Familiarize yourself with the rust-proofing industry, including trends, techniques, and best practices. Research the company you are applying to, including their products, services, and culture.

- Review their website, social media, and news articles

- Identify common interview questions specific to the industry

2. Highlight Relevant Skills and Experience

Emphasize your experience in surface preparation, coating application, and quality control. Quantify your accomplishments whenever possible.

- Use action verbs and specific examples to describe your work

- Show how your previous experience has equipped you for the role

3. Demonstrate Safety Knowledge

Rust-proofing can involve hazardous materials and equipment. Be prepared to discuss your knowledge of safety protocols and regulations.

- Highlight any safety certifications or training you have

- Provide examples of how you have implemented safety measures in previous roles

4. Ask Insightful Questions

Asking thoughtful questions during the interview shows that you are engaged and interested in the role. It also allows you to gather valuable information.

- Ask about the company’s approach to rust-proofing

- Inquire about opportunities for professional development

5. Dress Professionally and Be Punctual

First impressions matter. Dress appropriately and arrive on time for the interview.

- Choose clothing that is clean, pressed, and fits well

- Arrive at least 15 minutes early to show your respect for the interviewer’s time

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Rust Proofer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!