Are you gearing up for a career in Sack Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Sack Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

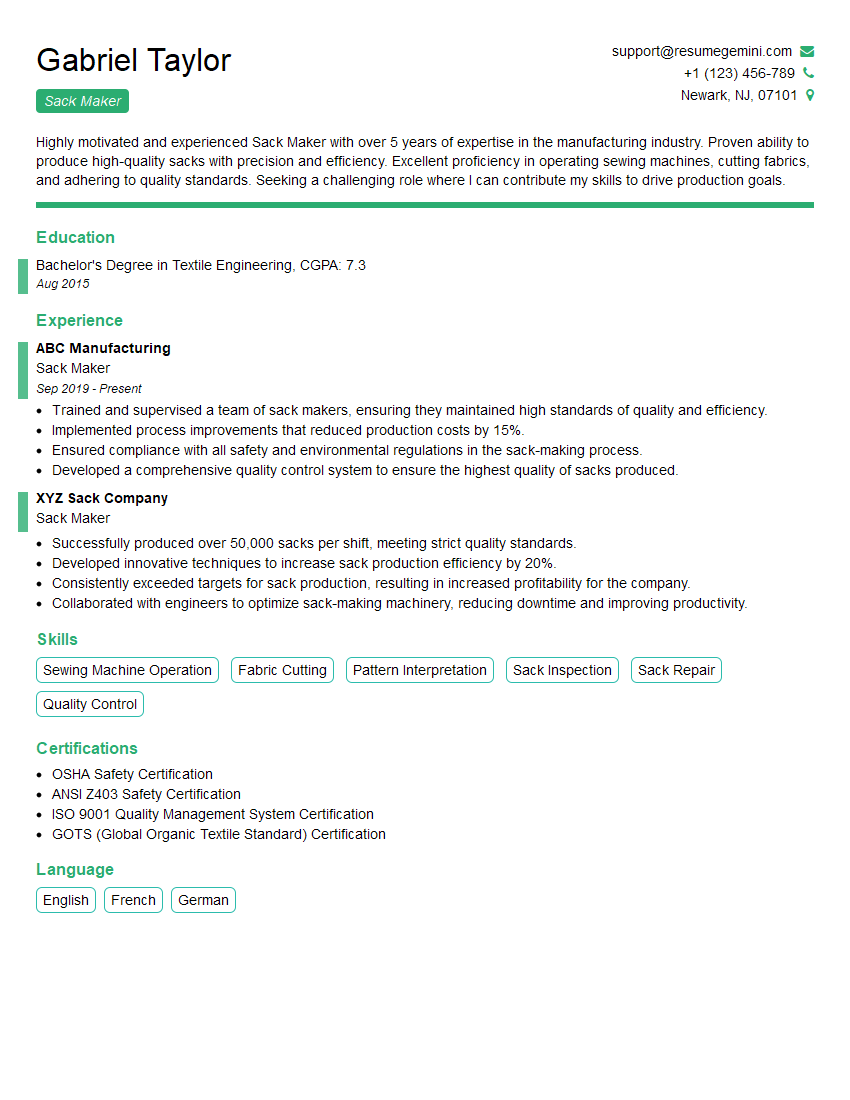

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sack Maker

1. What are the key steps involved in sack making process?

To produce sacks, the process involves several essential steps, such as:

- Selecting and preparing the raw materials (fabric or paper)

- Cutting the material to the desired size and shape

- Sewing or gluing the pieces together to form the sack

- Reinforcing the seams and adding any necessary features (e.g. handles, labels)

- Quality control and testing the sacks

2. Describe the different types of fabrics used in sack making and their properties.

Natural Fibers

- Cotton: Durable, breathable, absorbent

- Jute: Strong, inexpensive, biodegradable

- Burlap: Coarse, rugged, water-resistant

Synthetic Fibers

- Polypropylene: Lightweight, water-resistant, UV-resistant

- Polyethylene: Flexible, tear-resistant, moisture-proof

- Nylon: Strong, lightweight, abrasion-resistant

3. What is the difference between woven and non-woven sacks?

- Woven Sacks: Made from interlaced threads or yarn, providing strength and durability.

- Non-Woven Sacks: Produced by bonding fibers together without weaving, resulting in a softer, more flexible material.

4. How do you calculate the volume of a sack based on its dimensions?

- For rectangular sacks: Volume = Length x Width x Height

- For cylindrical sacks: Volume = π x Radius² x Height

5. What are the safety precautions that need to be taken when operating sack-making machinery?

- Wear appropriate protective gear (gloves, safety glasses, earplugs)

- Follow proper machine operation procedures

- Keep the work area clean and free of tripping hazards

- Be aware of potential pinch points and cutting hazards

- Report any safety concerns immediately

6. How do you ensure the quality of sacks before they are shipped to customers?

- Establish clear quality standards

- Conduct regular inspections at various stages of production

- Test sacks for strength, durability, and water resistance

- Maintain records of quality control measures

- Seek customer feedback and address any quality concerns promptly

7. What are the different types of closures used for sacks, and how do you choose the appropriate closure for a specific application?

- Drawstrings: Simple and inexpensive, suitable for small sacks or non-critical applications.

- Ties: Made from twine or plastic, provide a secure closure for heavier sacks.

- Velcro: Convenient and reusable, but may not be suitable for high-stress applications.

- Zip Closures: Offer a tamper-proof and moisture-resistant seal.

- Heat Seal Closures: Strong and durable, suitable for heavy-duty sacks.

8. How do you handle and store sacks to ensure their longevity?

- Store sacks in a dry and well-ventilated area.

- Avoid exposing sacks to excessive heat or moisture.

- Protect sacks from pests and rodents.

- Handle sacks carefully to prevent damage.

- Inspect sacks regularly for any signs of wear or tear.

9. What are the factors to consider when choosing the right sack for a specific application?

- Purpose: The intended use of the sack (e.g. storage, transportation, packaging)

- Contents: The type and volume of material to be stored or transported

- Size and Dimensions: The appropriate size and shape to accommodate the contents

- Material: The type of fabric or paper based on strength, durability, and water resistance requirements

- Closure: The most suitable closure method for the application

10. How do you stay updated on the latest advancements and best practices in sack making?

- Attend industry conferences and seminars

- Read trade publications and technical journals

- Network with other professionals in the field

- Explore online resources and research new technologies

- Seek opportunities for professional development and training

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sack Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sack Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sack Makers are responsible for operating and maintaining sack-making machines in a manufacturing environment. They ensure that the machines are operating smoothly, and they make adjustments to the machines to ensure that the sacks are made to the correct specifications. Sack Makers also perform general maintenance on the machines, such as cleaning and lubrication.

1. Set up and operate sack-making machines

Sack Makers are responsible for setting up and operating sack-making machines. This involves loading the machine with the proper materials, such as fabric and thread, and setting the machine to the correct settings. Sack Makers must also be able to operate the machine safely and efficiently.

- Load the machine with the proper materials, such as fabric and thread

- Set the machine to the correct settings

- Operate the machine safely and efficiently

2. Monitor the operation of the machines

Sack Makers are responsible for monitoring the operation of the machines. This involves watching for any problems, such as jams or tears in the fabric. Sack Makers must also be able to make adjustments to the machines to correct any problems.

- Watch for any problems, such as jams or tears in the fabric

- Make adjustments to the machines to correct any problems

3. Perform general maintenance on the machines

Sack Makers are responsible for performing general maintenance on the machines. This involves cleaning and lubricating the machines, and replacing any worn parts. Sack Makers must also be able to troubleshoot any problems with the machines.

- Clean and lubricate the machines

- Replace any worn parts

- Troubleshoot any problems with the machines

4. Ensure that the sacks are made to the correct specifications

Sack Makers are responsible for ensuring that the sacks are made to the correct specifications. This involves checking the sacks for any defects, such as holes or tears, and making sure that the sacks are the correct size and weight. Sack Makers must also be able to communicate any problems with the sacks to their supervisor.

- Check the sacks for any defects, such as holes or tears

- Make sure that the sacks are the correct size and weight

- Communicate any problems with the sacks to their supervisor

Interview Tips

Here are some tips for acing your interview for a Sack Maker position:

1. Research the company and the position

Before you go on your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also help you answer questions about the position.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work at the company

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Use the STAR method to answer questions

- Be prepared to talk about your skills and experience

- Be prepared to talk about why you are interested in the company and the position

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Avoid wearing strong perfumes or colognes

4. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you are running late, call or email the interviewer to let them know.

- Plan your route in advance

- Leave yourself plenty of time to get to the interview

- If you are running late, call or email the interviewer to let them know

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sack Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.