Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Saddle Stitching Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

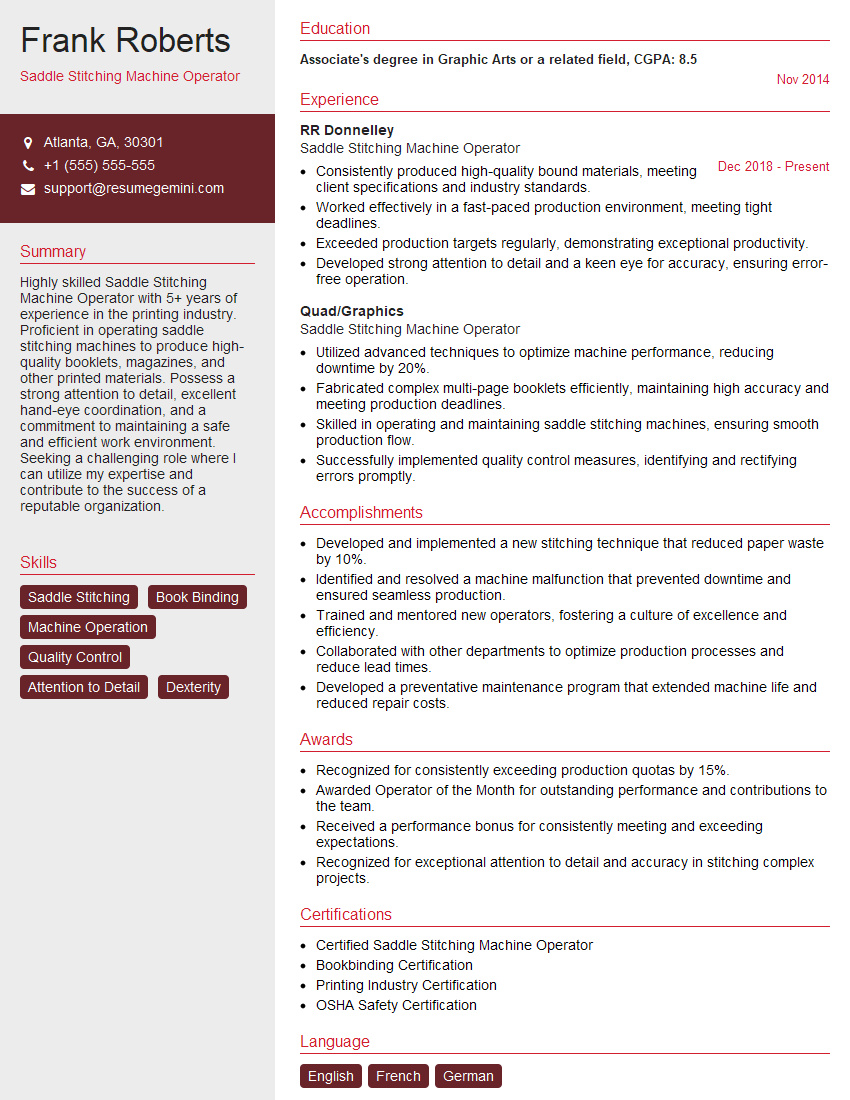

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Saddle Stitching Machine Operator

1. What are the different types of saddle stitching machines and their applications?

- Manual Saddle Stitching Machines: These are operated by hand and are suitable for smaller print runs.

- Semi-Automatic Saddle Stitching Machines: These machines require manual feeding of paper but automatically perform the stitching process.

- Automatic Saddle Stitching Machines: These machines fully automate the process, including feeding, stitching, and trimming.

2. Describe the process of saddle stitching in detail.

- Pre-Folding: The paper is folded into a desired format before stitching.

- Gathering: The folded sections are gathered in sequence.

- Jogging: The gathered sections are aligned to ensure proper stitching.

- Stitching: Wire staples are driven through the folded spine, binding the sections together.

- Trimming: Any excess paper around the edges is trimmed.

Quality Control Measures

- Proper staple placement and penetration

- Correct stitch spacing and alignment

- No tearing or damage to the paper

3. What are the common problems that can occur in saddle stitching and how do you troubleshoot them?

- Jamming: Check for paper misalignment, staple jams, or foreign objects in the machine.

- Double Stitching: Adjust the stitch spacing or check for faulty sensors.

- Skipped Stitches: Ensure proper staple loading, clean clogged needles, or adjust the machine settings.

- Wire Breaks: Replace dull staples, check for wire tension issues, or lubricate moving parts.

4. What maintenance procedures are required for saddle stitching machines?

- Daily: Clean work areas, remove paper scraps, and check staple supplies.

- Weekly: Oil moving parts, inspect needles and drivers for wear.

- Monthly: Perform thorough cleaning, adjust machine settings, and calibrate sensors.

- As Needed: Replace worn or damaged parts, including needles, drivers, and belts.

5. What are the safety precautions that should be followed when operating a saddle stitching machine?

- Wear appropriate safety gear, including gloves and safety glasses.

- Keep hands away from moving parts and needles.

- Never attempt to unjam the machine while it is running.

- Report any malfunctions or safety concerns promptly.

6. What is the best way to optimize the performance of a saddle stitching machine?

- Use high-quality paper to prevent jamming.

- Properly align and jog the paper before stitching.

- Adjust the machine settings according to the paper thickness and staple size.

- Regularly perform maintenance and cleaning to keep the machine in good condition.

7. What are the factors that affect the quality of saddle stitching?

- Paper quality and thickness

- Proper stitching spacing and alignment

- Quality of staples and wire

- Machine maintenance and calibration

8. How do you ensure that the finished product meets the customer’s specifications?

- Review the customer’s specifications carefully.

- Set up the machine according to the required settings.

- Perform quality checks throughout the process.

- Obtain customer approval before releasing the final product.

9. What is the importance of teamwork in a saddle stitching environment?

- Facilitates smooth operation and efficient workflow.

- Ensures proper communication and coordination among team members.

- Provides support and assistance during machine operation and troubleshooting.

- Contributes to maintaining a positive and productive work environment.

10. Describe a situation where you had to solve a complex problem related to saddle stitching.

- Problem: Machine repeatedly jammed due to paper misalignment.

- Actions: Inspected the paper feed system, adjusted the guides, and lubricated moving parts.

- Results: Paper flow improved, jamming resolved, and production resumed smoothly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Saddle Stitching Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Saddle Stitching Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Saddle stitching machine operators oversee the machines that seamlessly bind sheets of paper collectively into a cohesive unit. This position demands an astute eye for detail and the ability to work methodically.

1. Expertise in Saddle Stitching Machines

To excel in this role, proficiency in operating saddle stitching machines is essential. Ensuring precise alignment and proper stitching patterns is paramount to delivering high-quality outcomes.

2. Production and Quality Management

Operators are accountable for maintaining consistent output while upholding impeccable standards. They meticulously monitor machine performance, swiftly addressing any glitches to prevent production delays.

3. Inspection and Finishing

Post-stitching, operators carefully inspect each bound document to verify its integrity. They ensure that the stitches are secure, the pages are aligned correctly, and the overall appearance meets established quality standards.

4. Material Handling and Preparation

Handling paper stock, magazines, brochures, and other materials is an integral part of the job. Skillful operators seamlessly load and unload materials, ensuring smooth production flow.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some valuable tips:

1. Research the Company and Industry

Exhibiting knowledge about the company and the saddle stitching industry demonstrates your interest and commitment. Explore the company’s website, industry news, and relevant articles to gain insights.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating saddle stitching machines and any related experience or skills that align with the job requirements. Quantify your accomplishments with specific examples to showcase your impact.

3. Prepare for Common Interview Questions

Anticipate questions about your experience, skills, and why you’re interested in the position. Practice your responses, ensuring they are concise, clear, and highlight your qualifications.

4. Demonstrate Attention to Detail

This role places a premium on meticulousness. During the interview, be observant of details, ask clarifying questions, and present yourself professionally. These subtle cues can convey your attention to quality.

5. Seek Opportunities for Growth

Express your enthusiasm for learning and growing within the organization. Inquire about training opportunities or professional development programs that support your career aspirations.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Saddle Stitching Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.