Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Safety Glass Installer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Safety Glass Installer so you can tailor your answers to impress potential employers.

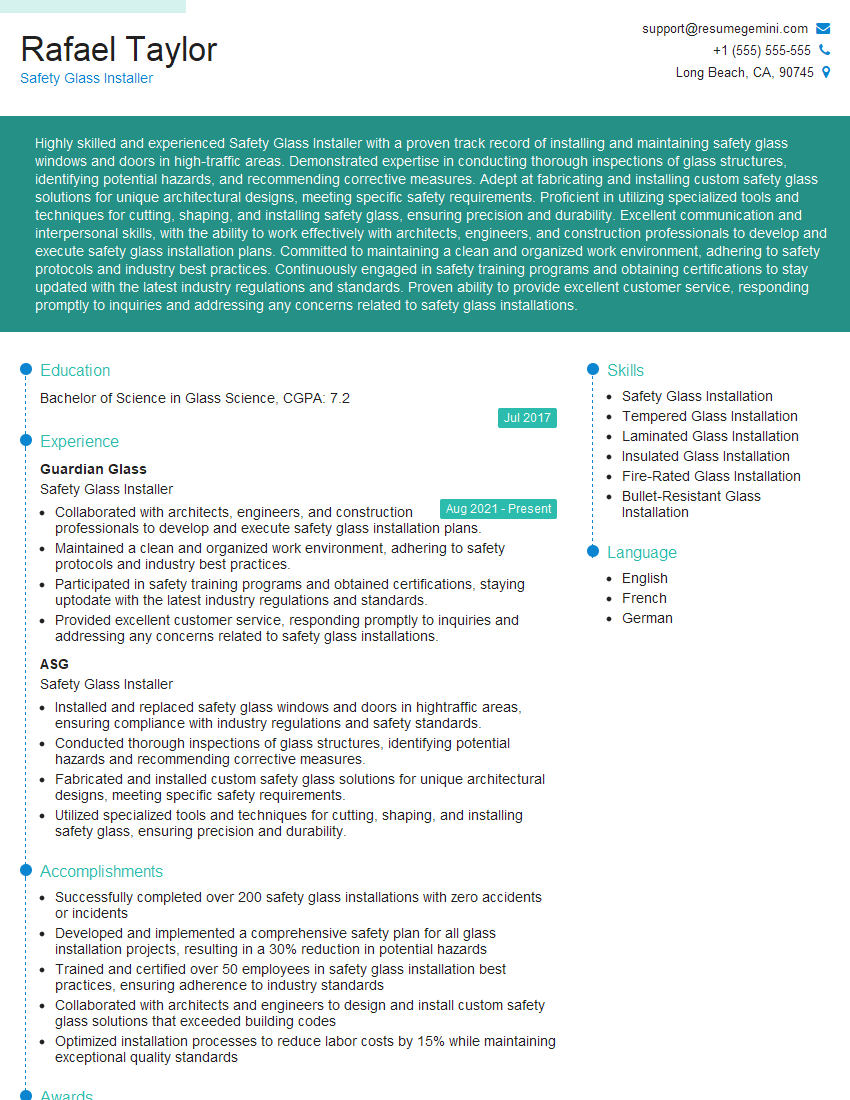

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Safety Glass Installer

1. What are the different types of safety glass and their applications?

- Annealed glass: It is the most common type of safety glass and is used in windows, doors, and other applications where there is a low risk of impact.

- Tempered glass: It is a type of safety glass that is four to five times stronger than annealed glass and is used in applications where there is a higher risk of impact, such as car windows and shower doors.

- Laminated glass: It is a type of safety glass that is made up of two or more layers of glass that are bonded together with a layer of plastic. It is used in applications where there is a need for both strength and transparency, such as windshields and bulletproof glass.

2. What are the different tools and equipment used in safety glass installation?

Hand tools

- Glazier’s knife

- Putty knife

- Hack saw

- Measuring tape

- Level

Power tools

- Drill

- Circular saw

- Table saw

- Miter saw

3. What are the steps involved in installing safety glass?

- Prepare the opening by cleaning it and making sure it is level.

- Cut the glass to size.

- Apply a bead of sealant around the perimeter of the opening.

- Set the glass in place and press it firmly into the sealant.

- Wipe away any excess sealant.

- Allow the sealant to cure for the manufacturer’s recommended time.

4. What are the safety precautions that must be taken when installing safety glass?

- Wear safety glasses, gloves, and protective clothing.

- Use sharp tools and equipment and handle them carefully.

- Be aware of your surroundings and be careful not to trip or fall.

- Follow the manufacturer’s instructions for the safe installation of safety glass.

5. What are the different types of glazing?

- Face glazing: It is a method of glazing in which the glass is set in a rabbet in the frame and held in place with putty or glazing points.

- Back glazing: It is a method of glazing in which the glass is set in a rabbet in the frame and held in place with clips or screws.

- Structural glazing: It is a method of glazing in which the glass is supported by a frameless system of metal or plastic extrusions.

6. What are the different types of sealants used in safety glass installation?

- Silicone sealant: It is a type of sealant that is used to seal joints between glass and other materials. It is flexible and resistant to water and UV radiation.

- Butyl sealant: It is a type of sealant that is used to seal joints between glass and metal. It is sticky and has a long service life.

- Polysulfide sealant: It is a type of sealant that is used to seal joints between glass and concrete. It is strong and durable.

7. What are the different types of hardware used in safety glass installation?

- Glazing points: They are small metal clips that are used to hold glass in place in a rabbet.

- Glazing tape: It is a type of tape that is used to seal joints between glass and other materials.

- Glazing gaskets: They are pre-formed rubber or plastic gaskets that are used to seal joints between glass and other materials.

8. What are the different types of safety glass films?

- Security film: It is a type of safety glass film that is used to protect glass from breakage. It is made of a strong and durable material that can withstand impacts from objects such as rocks and bricks.

- Solar control film: It is a type of safety glass film that is used to reduce the amount of heat and UV radiation that enters a building. It is made of a reflective material that can block up to 99% of the sun’s rays.

- Privacy film: It is a type of safety glass film that is used to obscure the view of a room from the outside. It is made of a translucent material that can block up to 100% of the light.

9. How do you measure and cut safety glass?

- To measure safety glass, use a tape measure to determine the length and width of the opening.

- To cut safety glass, use a glass cutter to score the glass along the measured lines.

- Once the glass is scored, snap it along the score line to break it.

10. What are the different types of safety glass breakage?

- Spontaneous breakage: It is a type of safety glass breakage that occurs without any apparent cause. It is caused by a defect in the glass.

- Impact breakage: It is a type of safety glass breakage that occurs when the glass is struck by an object. It is caused by the force of the impact.

- Thermal breakage: It is a type of safety glass breakage that occurs when the glass is subjected to extreme heat or cold. It is caused by the expansion or contraction of the glass.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Safety Glass Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Safety Glass Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Safety Glass Installers are responsible for the safe and secure installation of safety glass. These professionals work with a range of safety glass products, including tempered glass, laminated glass, and wired glass. They are responsible for ensuring that the glass is installed correctly and meets all safety codes and regulations. Safety Glass Installers typically perform the following tasks:

1. Prepare the work area

This includes clearing the area of any obstacles, setting up the necessary tools and equipment, and ensuring that the work area is safe and secure.

2. Cut the glass

Safety Glass Installers use a variety of tools to cut the glass, including hand-held glass cutters, power saws, and water jets. They must be precise in their cutting to ensure that the glass fits properly in the frame.

3. Install the glass

Safety Glass Installers use a variety of techniques to install the glass, including glazing, caulking, and taping. They must ensure that the glass is installed securely and that it meets all safety codes and regulations.

4. Inspect the work area

Once the glass is installed, Safety Glass Installers must inspect the work area to ensure that it is safe and secure. They must also check the glass for any damage or defects.

Interview Tips

Interview Preparation Tips for Safety Glass Installers

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you to better understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, social media pages, and in online news articles.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Highlight your skills and experience

In your interview, be sure to highlight your skills and experience that are relevant to the position you are applying for. For example, if you have experience installing safety glass in commercial buildings, be sure to mention this in your interview.

4. Be prepared to talk about your safety record

Safety is a top priority for Safety Glass Installers. In your interview, be prepared to talk about your safety record and how you have maintained a safe work environment in previous positions.

5. Dress professionally

First impressions matter, so be sure to dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also arrive on time for your interview and be polite and respectful to the interviewer.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Safety Glass Installer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.