Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Salt Refiner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

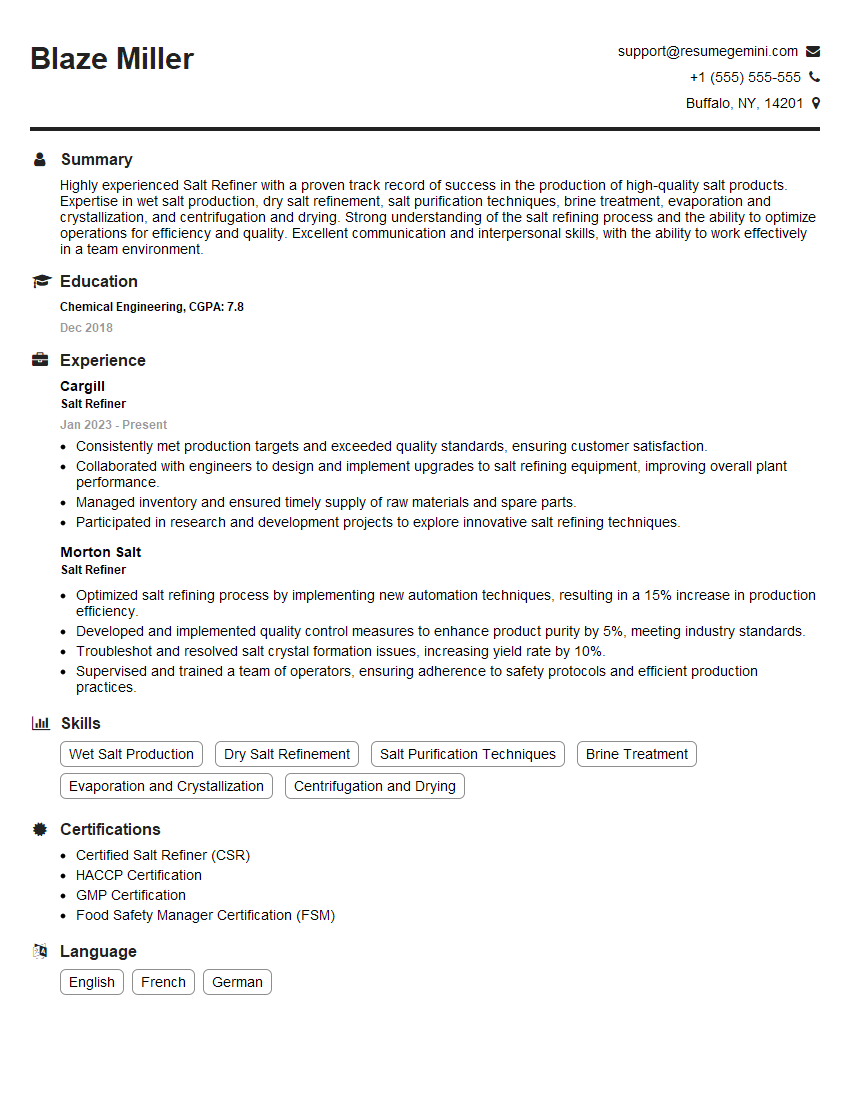

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Salt Refiner

1. Explain the different methods of salt refining and their advantages and disadvantages?

- Solar Evaporation: This method involves evaporating seawater or brine under the sun’s heat to produce salt. Advantages: low energy consumption, environmentally friendly. Disadvantages: slow process, dependent on weather conditions.

- Vacuum Pan Evaporation: This method uses vacuum evaporators to reduce the pressure, lower the boiling point of brine, and accelerate evaporation. Advantages: faster process, produces higher-quality salt. Disadvantages: energy-intensive, requires specialized equipment.

- Spray Drying: This method involves atomizing brine into a hot air stream, which evaporates the water rapidly. Advantages: produces fine, uniform salt crystals, fast process. Disadvantages: energy-intensive, requires specialized equipment.

2. What are the key impurities found in raw salt and how do you remove them during the refining process?

Types of Impurities

- Calcium sulfate (gypsum)

- Magnesium chloride (bittern)

- Sodium sulfate (Glauber’s salt)

Removal Methods

- Precipitation: Adding chemicals to brine to form insoluble compounds that settle out.

- Crystallization: Controlling temperature and concentration to selectively crystallize the desired salt.

- Washing: Dissolving salt in water and filtering out impurities.

- Ion Exchange: Using resins to exchange unwanted ions with desirable ones.

3. What are the different grades of salt and how are they classified?

- Table Salt: Refined, iodized salt with a particle size of less than 1 mm.

- Industrial Salt: Coarse, unrefined salt used in chemical processes and water treatment.

- Sea Salt: Salt harvested from seawater, containing trace minerals and a coarser texture.

- Kosher Salt: Coarse, flaky salt used in kosher cuisine for seasoning and removing blood from meat.

- Rock Salt: Unrefined salt mined from salt beds, typically used for melting ice and preserving hides.

4. Describe the quality control measures implemented in salt refining to ensure product purity and consistency?

- Sampling: Collecting and analyzing samples at various stages of the process.

- Physical Tests: Determining particle size distribution, moisture content, and solubility.

- Chemical Tests: Measuring ion concentrations, impurities, and trace elements.

- Microbiological Tests: Ensuring the absence of harmful microorganisms.

- Traceability: Maintaining records of the origin and processing history of each batch.

5. What are the safety precautions that must be taken when handling large quantities of salt?

- Skin Protection: Wear gloves and protective clothing to prevent irritation.

- Eye Protection: Use safety glasses or goggles to protect from dust and splashes.

- Respiratory Protection: Wear a mask in dusty environments.

- Ventilation: Ensure adequate ventilation to prevent dust accumulation.

- Handling Equipment: Use appropriate equipment for lifting and moving heavy salt bags.

6. How do you optimize the efficiency of a salt refining plant?

- Process Optimization: Fine-tuning evaporation rates, temperatures, and crystallization conditions.

- Equipment Maintenance: Regularly inspecting and maintaining equipment to ensure optimal performance.

- Waste Reduction: Implementing measures to minimize brine discharge and recycle waste streams.

- Employee Training: Providing training to operators on best practices and troubleshooting techniques.

- Data Analysis: Monitoring process data and using analytics to identify areas for improvement.

7. What are the emerging trends in salt refining and how do you stay up-to-date with them?

- Sustainable Refining: Focus on reducing environmental impact and optimizing resource usage.

- Specialty Salt Production: Developing new and innovative salt products with unique flavors and properties.

- Automation: Utilizing advanced technologies to automate processes and improve efficiency.

- Industry Research: Monitoring scientific publications and attending conferences to stay abreast of latest developments.

- Networking: Engaging with industry professionals and organizations to exchange knowledge and best practices.

8. How do you handle and resolve production issues that arise during salt refining?

- Troubleshooting: Identifying the root cause of the issue through analysis of process parameters and equipment.

- Corrective Action: Implementing measures to rectify the issue and prevent recurrence.

- Communication: Informing supervisors, engineers, and operators of the issue and its resolution.

- Documentation: Recording the issue, troubleshooting steps, and corrective actions taken for future reference.

- Continuous Improvement: Using lessons learned from resolved issues to enhance process efficiency and prevent similar issues in the future.

9. What are your strengths and weaknesses as a Salt Refiner?

- Strengths:

- Strong understanding of salt refining processes and principles.

- Expertise in process optimization and efficiency improvement.

- Excellent troubleshooting and problem-solving skills.

- Weaknesses:

- Limited experience with emerging salt refining technologies (e.g., automation, sustainable refining).

- Seeking to expand my knowledge and stay up-to-date with the latest industry developments.

10. What are your salary expectations for this role?

- Based on my experience, skills, and the market value for similar roles, my salary expectations are within the range of $X to $Y.

- I am flexible and willing to negotiate within a reasonable range, depending on the benefits package and career growth opportunities.

- I am confident that I can make a significant contribution to your organization and deliver exceptional results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Salt Refiner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Salt Refiner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Salt Refiner is responsible for the refining and purification of salt to produce high-quality products for various industries. Their key responsibilities include:

1. Salt Production and Processing

Ensuring the smooth operation of salt production equipment and machinery, including evaporators, crystallizers, and dryers.

- Monitoring and controlling the production process to maintain optimal salt quality and yield.

- Implementing and enforcing safety protocols to prevent accidents and ensure a safe working environment.

2. Salt Refining and Purification

Operating and maintaining refining equipment to remove impurities and refine salt to meet industry standards.

- Establishing and adhering to quality control procedures to ensure the production of high-purity salt.

- Conducting regular inspections and tests on salt samples to monitor quality and detect any deviations.

3. Equipment Maintenance and Troubleshooting

Maintaining, repairing, and troubleshooting salt refining equipment to ensure optimal performance.

- Performing routine maintenance and inspections to identify and address potential issues promptly.

- Troubleshooting and resolving equipment breakdowns to minimize production downtime.

4. Process Optimization and Improvement

Continuously seeking opportunities to improve the salt refining process and enhance efficiency.

- Analyzing production data and identifying areas for improvement.

- Implementing new techniques and technologies to increase productivity and reduce costs.

Interview Tips

To ace your interview for a Salt Refiner position, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, values, and current projects. Understand the specific responsibilities and requirements of the Salt Refiner role.

- Visit the company’s website and read industry news to gain insights.

- Connect with current or former employees on LinkedIn to learn about the company culture and work environment.

2. Highlight Your Technical Skills

Emphasize your expertise in salt production, refining, and purification techniques. Demonstrate your understanding of the equipment and processes involved.

- Quantify your accomplishments using specific metrics, such as production yield or impurity reduction.

- Provide examples of how you have solved technical problems or implemented improvements in previous roles.

3. Showcase Your Problem-Solving Abilities

Salt refining often involves troubleshooting and problem-solving. Highlight your analytical thinking and ability to identify and resolve issues.

- Describe a situation where you encountered a production problem and the steps you took to diagnose and address it.

- Explain your approach to continuous improvement and how you seek opportunities to optimize processes.

4. Emphasize Safety and Quality Control

Safety and quality are paramount in salt refining. Demonstrate your commitment to maintaining a safe work environment and ensuring the production of high-quality salt.

- Describe your experience in implementing and enforcing safety protocols.

- Highlight your understanding of quality control procedures and your role in maintaining product purity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Salt Refiner role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.