Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sample Mounter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

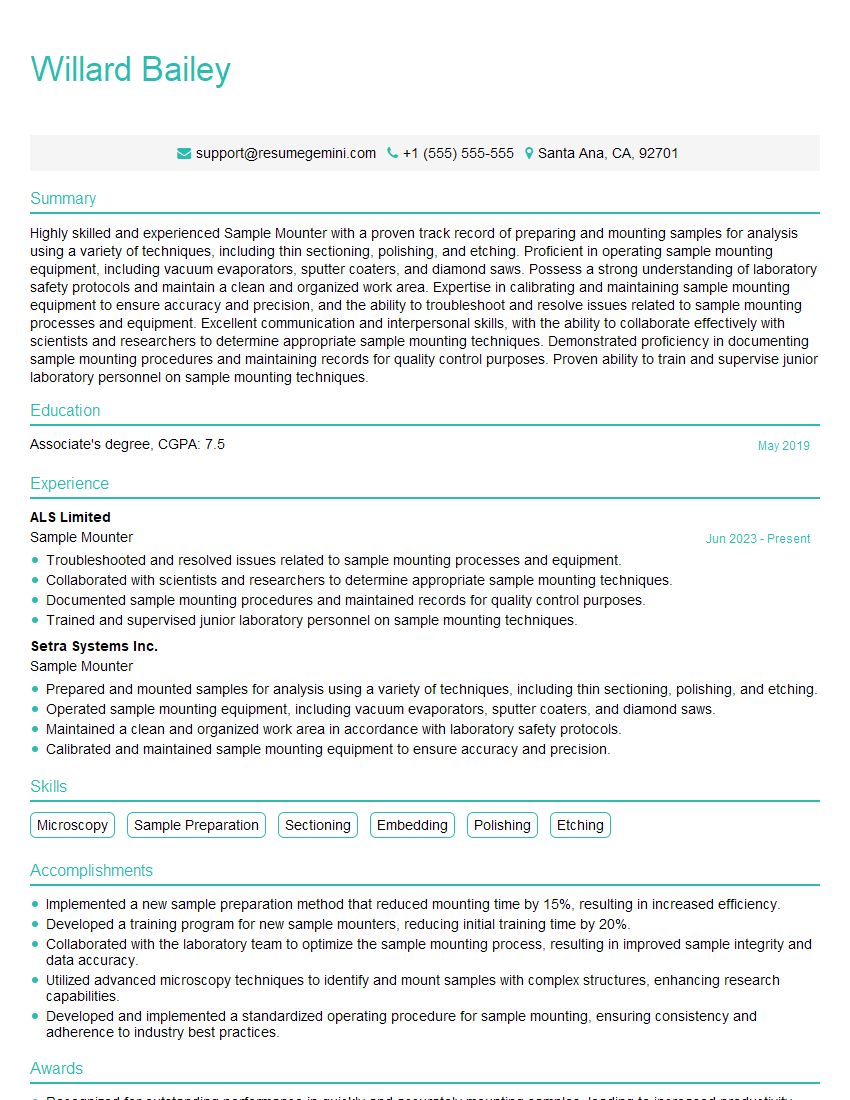

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sample Mounter

1. Explain the steps involved in mounting a sample for SEM imaging?

Steps involved in mounting a sample for SEM imaging

- Prepare the sample surface by cutting, polishing, or etching to reveal the desired features.

- Clean the sample surface to remove any contaminants that could interfere with imaging.

- Attach the sample to a stub or holder using conductive adhesive or carbon tape.

- Coat the sample with a thin layer of conductive material, such as gold or platinum, to prevent charging during imaging.

- Place the sample in the SEM chamber and align it with the electron beam.

2. What are the different types of adhesives used for sample mounting?

Conductive adhesives

- Silver epoxy

- Carbon paste

- Copper tape

Non-conductive adhesives

- Super glue

- Epoxy

- Double-sided tape

3. What is the purpose of coating a sample with a conductive material before SEM imaging?

Coating a sample with a conductive material before SEM imaging serves two main purposes:

- Prevent charging: When an electron beam interacts with a non-conductive sample, it can cause the sample to accumulate charge. This charge can distort the image and make it difficult to interpret.

- Enhance secondary electron emission: Conductive coatings enhance the emission of secondary electrons, which are essential for creating the image in SEM.

4. What are the different techniques used to coat samples for SEM imaging?

The following techniques are commonly used to coat samples for SEM imaging:

- Thermal evaporation

- Sputter coating

- Chemical vapor deposition (CVD)

- Electroless plating

5. What are the factors to consider when selecting a coating material for SEM imaging?

The following factors should be considered when selecting a coating material for SEM imaging:

- Conductivity: The coating material should be highly conductive to prevent charging.

- Thickness: The coating should be thin enough to allow the electron beam to penetrate the sample, but thick enough to prevent charging.

- Adhesion: The coating should adhere well to the sample surface.

- Reactivity: The coating material should not react with the sample.

6. How do you ensure that a sample is properly coated for SEM imaging?

To ensure that a sample is properly coated for SEM imaging, the following steps can be taken:

- Inspect the sample under a microscope to check for any defects in the coating.

- Measure the thickness of the coating using a film thickness gauge.

- Test the conductivity of the coating using a conductivity meter.

7. What are the common problems associated with sample mounting for SEM imaging?

Common problems associated with sample mounting for SEM imaging include:

- Charging: This can be caused by a non-conductive sample or a coating that is too thin.

- Sample movement: This can be caused by a loose sample or a coating that is not sufficiently adhesive.

- Contamination: This can be caused by improper cleaning of the sample or the use of contaminated materials.

8. How do you troubleshoot problems with sample mounting for SEM imaging?

To troubleshoot problems with sample mounting for SEM imaging, the following steps can be taken:

- Charging: If the sample is charging, try using a thicker coating or a more conductive coating material.

- Sample movement: If the sample is moving, try using a more adhesive coating or a different mounting method.

- Contamination: If the sample is contaminated, try cleaning it again with a different solvent or using a different mounting material.

9. What are the safety precautions that should be taken when mounting samples for SEM imaging?

The following safety precautions should be taken when mounting samples for SEM imaging:

- Wear gloves and a lab coat to protect your skin from chemicals.

- Use a fume hood when working with chemicals.

- Do not touch the sample with your bare hands.

- Dispose of chemicals and waste properly.

10. What are the latest advancements in sample mounting for SEM imaging?

Some of the latest advancements in sample mounting for SEM imaging include:

- Nanomanipulators: These devices can be used to precisely position samples on a stub or holder.

- Conductive adhesives: These adhesives have been developed to provide better conductivity and adhesion than traditional adhesives.

- New coating materials: New coating materials have been developed to provide better conductivity, adhesion, and resistance to charging.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sample Mounter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sample Mounter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Sample Mounter is a crucial member of a research and development team, responsible for preparing and mounting samples for analysis. Their key responsibilities include:

1. Sample Preparation and Mounting

Preparing samples for analysis by cutting, grinding, polishing, or embedding them using appropriate techniques and materials.

- Selecting and using the appropriate mounting medium and embedding techniques based on sample characteristics.

- Operating mounting equipment and machinery safely and efficiently.

2. Quality Control and Maintenance

Ensuring the quality of prepared samples by inspecting them for defects, contamination, and proper mounting.

- Maintaining and calibrating mounting equipment regularly.

- Following established quality control procedures and documentation.

3. Equipment and Materials Management

Managing and maintaining equipment and materials used in the sample mounting process.

- Ordering and maintaining inventory of mounting supplies and consumables.

- Performing routine maintenance and troubleshooting of equipment.

4. Safety and Compliance

Adhering to all safety regulations and guidelines related to the handling and use of chemicals, equipment, and samples.

- Wearing appropriate personal protective equipment.

- Following established waste disposal protocols.

Interview Tips

To ace your interview for a Sample Mounter position, consider the following tips:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Sample Mounter role. Learn about their industry, products or services, and any recent developments. Understanding the company’s goals and values will allow you to tailor your answers.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your technical skills in sample preparation and mounting, including your proficiency in different techniques and equipment. Quantify your experience whenever possible, providing specific examples of projects or accomplishments.

3. Demonstrate Quality Consciousness

Sample Mounters play a vital role in ensuring the quality of research data. Highlight your attention to detail, meticulousness, and ability to adhere to strict quality control procedures. Describe instances where you identified and resolved issues related to sample preparation or mounting.

4. Emphasize Safety and Compliance

Safety is paramount in a laboratory setting. Stress your commitment to safety and compliance with industry regulations. Provide examples of how you prioritize safety in your work, such as following proper handling procedures for chemicals or maintaining a clean and organized work area.

5. Prepare Questions for the Interviewer

Preparing questions for the interviewer demonstrates your interest and engagement in the role. Ask about the company’s research priorities, the scope of the Sample Mounter position, and opportunities for professional development. This shows that you are not only interested in the job but also in the company’s culture and potential.

Next Step:

Now that you’re armed with the knowledge of Sample Mounter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Sample Mounter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini