Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Sand Blaster interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Sand Blaster so you can tailor your answers to impress potential employers.

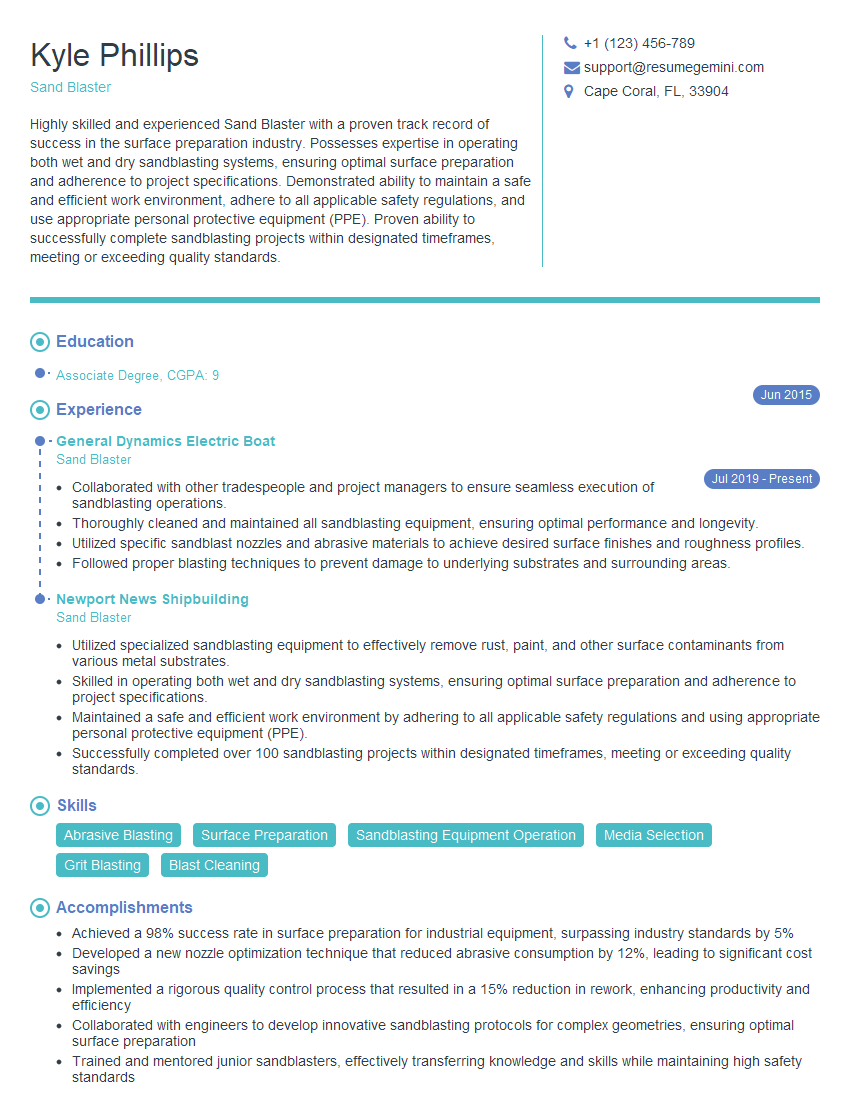

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sand Blaster

1. Describe the types of sandblasting equipment and their uses?

There are two main types of sandblasting equipment: pressure-fed and suction-fed. Pressure-fed sandblasters use compressed air to propel the abrasive material, while suction-fed sandblasters use a vacuum to create suction that draws the abrasive material through the nozzle. Pressure-fed sandblasters are more powerful and can be used for a wider variety of applications, while suction-fed sandblasters are less powerful and are typically used for smaller jobs.

2. What are the different types of abrasives used in sandblasting?

Abrasives commonly used in Sand Blasting

- Sand (silica)

- Glass beads

- Aluminum oxide

- Steel grit

Factors to consider when choosing an abrasive

- The type of surface being blasted

- The desired finish

- The environmental regulations in the area where the blasting will be taking place

3. What are the safety precautions that must be taken when sandblasting?

- Wear appropriate personal protective equipment (PPE), including a respirator, gloves, eye protection, and hearing protection.

- Work in a well-ventilated area.

- Keep the sandblaster nozzle pointed away from yourself and others.

- Never sandblast a closed container.

- Inspect the sandblaster and all hoses and fittings before each use.

- Follow all the manufacturer’s instructions for safe operation.

4. What are the common applications of sandblasting?

- Removing paint, rust, and other coatings from metal surfaces

- Preparing surfaces for painting or other coatings

- Cleaning and restoring stone and masonry surfaces

- Etching glass and other materials

- Creating decorative finishes on metal, wood, and other surfaces

5. What are the advantages and disadvantages of sandblasting?

Advantages

- Can be used to remove a wide variety of coatings and contaminants

- Can be used to prepare surfaces for painting or other coatings

- Can be used to clean and restore stone and masonry surfaces

- Can be used to create decorative finishes

Disadvantages

- Can be a noisy and dusty process

- Can be harmful to the environment if not done properly

- Can be dangerous if not done properly

6. What is the difference between sandblasting and soda blasting?

Sandblasting uses sand or other abrasive materials to remove coatings and contaminants from surfaces. Soda blasting uses sodium bicarbonate as the abrasive material. Soda blasting is less aggressive than sandblasting and is often used on delicate surfaces or where environmental concerns are a factor.

7. What are the different types of nozzles used in sandblasting?

- Venturi nozzles

- Nozzle Extensions

- Blast Nozzles

Factors to consider when choosing a nozzle

- The type of abrasive being used

- The desired finish

- The size of the area being blasted

8. How do you calculate the amount of abrasive needed for a sandblasting project?

- Determine the square footage of the area to be blasted

- Multiply the square footage by the thickness of the coating being removed

- Multiply the result by the coverage rate of the abrasive being used

9. What are the different types of dust collection systems used in sandblasting?

- Cyclone dust collectors

- Fabric filter dust collectors

- Wet dust collectors

Factors to consider when choosing a dust collection system

- The type of abrasive being used

- The size of the area being blasted

- The environmental regulations in the area where the blasting will be taking place

10. What are the different types of surface preparation methods used before sandblasting?

- Chemical cleaning

- Mechanical cleaning

- Thermal cleaning

Factors to consider when choosing a surface preparation method

- The type of surface being blasted

- The desired finish

- The environmental regulations in the area where the blasting will be taking place

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sand Blaster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sand Blaster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sand Blasters are responsible for preparing surfaces for coating or finishing by removing rust, paint, or other contaminants using a high-pressure stream of abrasive material. They perform a variety of tasks, including:

1. Preparation

Inspect surfaces to determine the appropriate abrasive material and nozzle size.

- Set up and operate sandblasting equipment, including compressors, hoses, and nozzles.

- Test surfaces to ensure proper adhesion and surface preparation.

2. Sandblasting

Wear protective gear, such as respirators, gloves, and eye protection.

- Direct the stream of abrasive material at the surface to remove rust, paint, or other contaminants.

- Control the pressure and angle of the abrasive stream to achieve the desired surface finish.

3. Clean-up

Clean up the work area after sandblasting, including removing spent abrasive material and debris.

- Dispose of spent abrasive material and debris in accordance with environmental regulations.

- Inspect the surface to ensure that it is clean and free of contaminants.

4. Maintenance

Maintain and repair sandblasting equipment, including compressors, hoses, and nozzles.

- Inspect equipment regularly to identify potential problems.

- Perform routine maintenance and repairs to ensure equipment is in good working order.

Interview Tips

To ace an interview for a Sand Blaster position, candidates should prepare by researching the company and the specific role they are applying for. They should also practice answering common interview questions and be familiar with the key job responsibilities. Here are some additional tips:

1. Research the company

Visit the company’s website to learn about their mission, values, and products or services. This will help you understand their culture and whether you are a good fit for the company.

2. Practice answering common interview questions

There are several common interview questions that you are likely to be asked, such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?” Practice answering these questions concisely and confidently.

3. Be familiar with the key job responsibilities

Make sure you understand the key job responsibilities of a Sand Blaster. This will help you answer questions about your experience and qualifications, and it will also show the interviewer that you are knowledgeable about the role.

4. Be prepared to talk about your safety experience

Sandblasting is a potentially hazardous job, so employers will want to know that you are familiar with safety procedures. Be prepared to talk about your experience with safety equipment and procedures, and how you would handle potential hazards.

5. Be prepared to demonstrate your physical fitness

Sandblasting can be physically demanding, so employers will want to know that you are fit enough to perform the job. Be prepared to demonstrate your physical fitness by lifting weights or performing other physical tasks.

6. Ask questions

Asking questions at the end of the interview is a great way to show your interest in the position and the company. It also gives you a chance to learn more about the role and the company culture. Prepare a few questions to ask the interviewer, such as “What is the company’s safety record?” or “What are the opportunities for advancement?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sand Blaster interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.