Feeling lost in a sea of interview questions? Landed that dream interview for Sand Cutter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Sand Cutter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

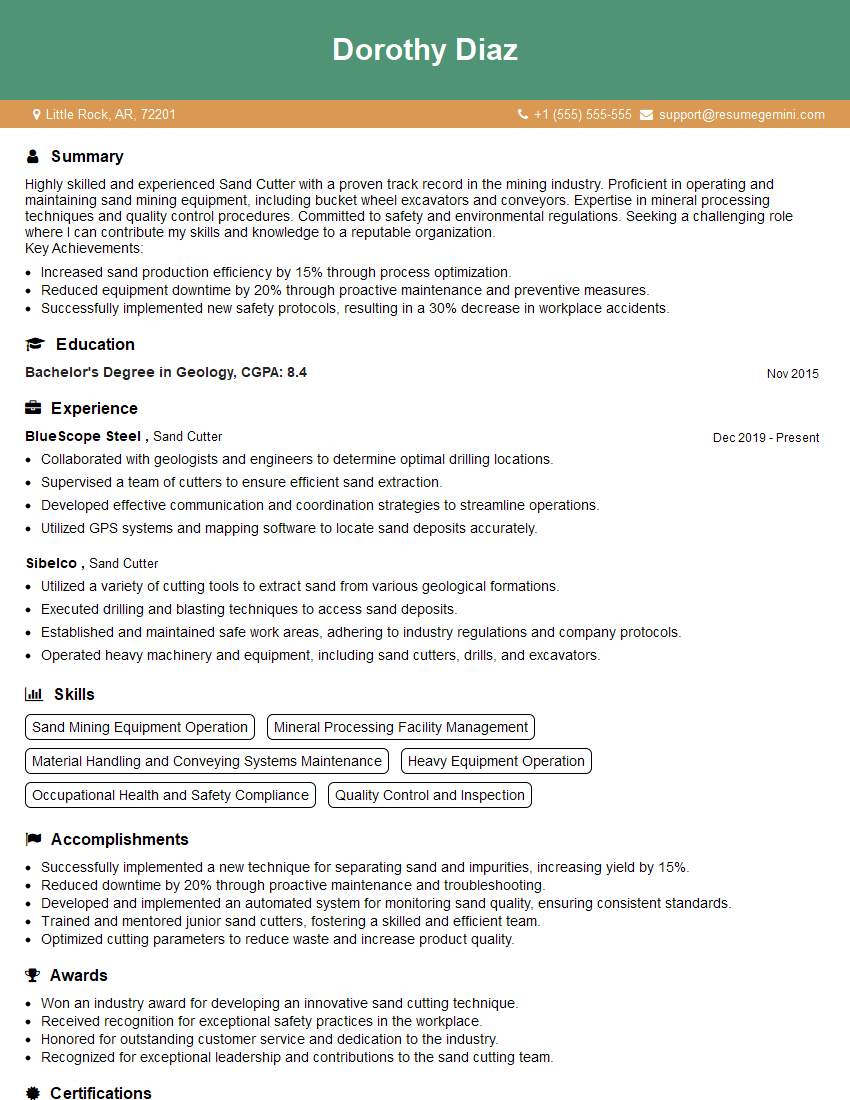

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sand Cutter

1. What are the key factors to consider when setting up a sand cutting machine?

The key factors to consider when setting up a sand cutting machine are:

- The type of sand being used

- The desired cut quality

- The production rate required

- The available budget

2. How do you maintain a sand cutting machine to ensure optimal performance?

Regular maintenance

- Cleaning the machine regularly to remove sand and dust buildup

- Inspecting the machine for wear and tear

- Replacing worn or damaged parts

Preventive maintenance

- Performing regular inspections and tune-ups

- Following the manufacturer’s recommended maintenance schedule

3. What are the common troubleshooting steps for a sand cutting machine that is not cutting properly?

The common troubleshooting steps for a sand cutting machine that is not cutting properly are:

- Checking the sand supply to ensure that it is adequate and free of contaminants

- Inspecting the cutting head for wear or damage

- Adjusting the cutting pressure and speed

- Checking the machine’s electrical connections

4. What are the different types of sand cutting nozzles?

The different types of sand cutting nozzles are:

- Round nozzles

- Flat nozzles

- Tapered nozzles

- Venturi nozzles

5. How do you determine the correct nozzle size for a sand cutting machine?

The correct nozzle size for a sand cutting machine is determined by the following factors:

- The type of sand being used

- The desired cut quality

- The production rate required

- The available budget

6. What are the safety precautions that must be taken when operating a sand cutting machine?

The safety precautions that must be taken when operating a sand cutting machine are:

- Wearing appropriate personal protective equipment (PPE), including eye protection, ear protection, and respiratory protection

- Keeping the work area clean and free of debris

- Using proper ventilation to remove dust and fumes

- Following the manufacturer’s operating instructions

7. How do you calculate the cost of a sand cutting operation?

The cost of a sand cutting operation is calculated by taking into account the following factors:

- The cost of the sand

- The cost of the machine

- The cost of labor

- The cost of overhead

8. What are the advantages of using a sand cutting machine over other cutting methods?

The advantages of using a sand cutting machine over other cutting methods are:

- Sand cutting is a relatively inexpensive process

- Sand cutting can be used to cut a wide variety of materials

- Sand cutting produces a high-quality cut

- Sand cutting is a versatile process that can be used for a variety of applications

9. What are the disadvantages of using a sand cutting machine?

The disadvantages of using a sand cutting machine are:

- Sand cutting can be a slow process

- Sand cutting can produce dust and fumes

- Sand cutting can be noisy

- Sand cutting can be hazardous if not used properly

10. What are the future trends in sand cutting technology?

The future trends in sand cutting technology include:

- The development of new and improved sand cutting nozzles

- The development of new and improved sand cutting machines

- The development of new and improved sand cutting processes

- The development of new and improved sand cutting applications

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sand Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sand Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sand Cutters are responsible for cutting and shaping sand to create molds and patterns used in various industries, including construction and manufacturing. Their duties involve operating specialized equipment and ensuring the precise dimensions and quality of the sand products.

1. Sand Cutting and Shaping

Key responsibilities include cutting and shaping sand to meet specific specifications and dimensions.

- Operate sand cutting machines to cut sand blocks to desired sizes and shapes.

- Use templates, patterns, and measurements to ensure accurate cutting and shaping.

2. Machine Operation and Maintenance

Sand Cutters are responsible for operating and maintaining specialized sand cutting equipment.

- Operate and maintain sand cutting machines, ensuring optimal performance and safety.

- Conduct regular inspections and maintenance to prevent breakdowns and ensure smooth operations.

3. Quality Control and Inspection

Sand Cutters play a crucial role in ensuring the quality of sand products.

- Inspect sand products for defects, ensuring they meet required specifications.

- Monitor sand quality and make adjustments to cutting and shaping processes as needed.

4. Health and Safety Compliance

Sand Cutters must adhere to health and safety regulations to ensure a safe work environment.

- Follow established health and safety protocols while operating machinery and handling materials.

- Wear appropriate personal protective equipment (PPE) to minimize risks associated with cutting and shaping sand.

Interview Preparation Tips

To effectively prepare for an interview for a Sand Cutter position, candidates should focus on highlighting their technical skills, experience, and commitment to safety. Here are some crucial tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and specific requirements for the Sand Cutter role. This will demonstrate your interest and understanding of the position.

- Visit the company’s website to gather information about its products, services, and company culture.

- Review the job description thoroughly to identify key responsibilities and qualifications.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating sand cutting machines and your understanding of sand cutting techniques. Provide specific examples to demonstrate your experience.

- Describe your experience in cutting and shaping sand to precise dimensions using different machines.

- Explain your knowledge of sand properties and how you adjust cutting parameters accordingly.

3. Showcase Your Safety Awareness

Safety is paramount in this role. Highlight your commitment to following established safety protocols and your experience in maintaining a safe work environment.

- Discuss your understanding of potential hazards associated with sand cutting and how you mitigate risks.

- Provide examples of your proactive approach to safety, such as conducting regular equipment inspections and reporting any potential issues.

4. Prepare for Common Interview Questions

Research and practice answering common interview questions related to your skills, experience, and qualifications. Anticipate questions about your knowledge of sand cutting, equipment operation, and safety measures.

- Practice describing your experience in operating specific sand cutting machines.

- Prepare examples of how you have ensured the quality of sand products and adhered to safety regulations.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview, reflecting the professional nature of the position. Punctuality demonstrates respect for the interviewer’s time.

- Wear clean and ironed business attire that is appropriate for a manufacturing environment.

- Plan your route in advance to avoid any delays and arrive on time for your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sand Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!