Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sand Drier position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

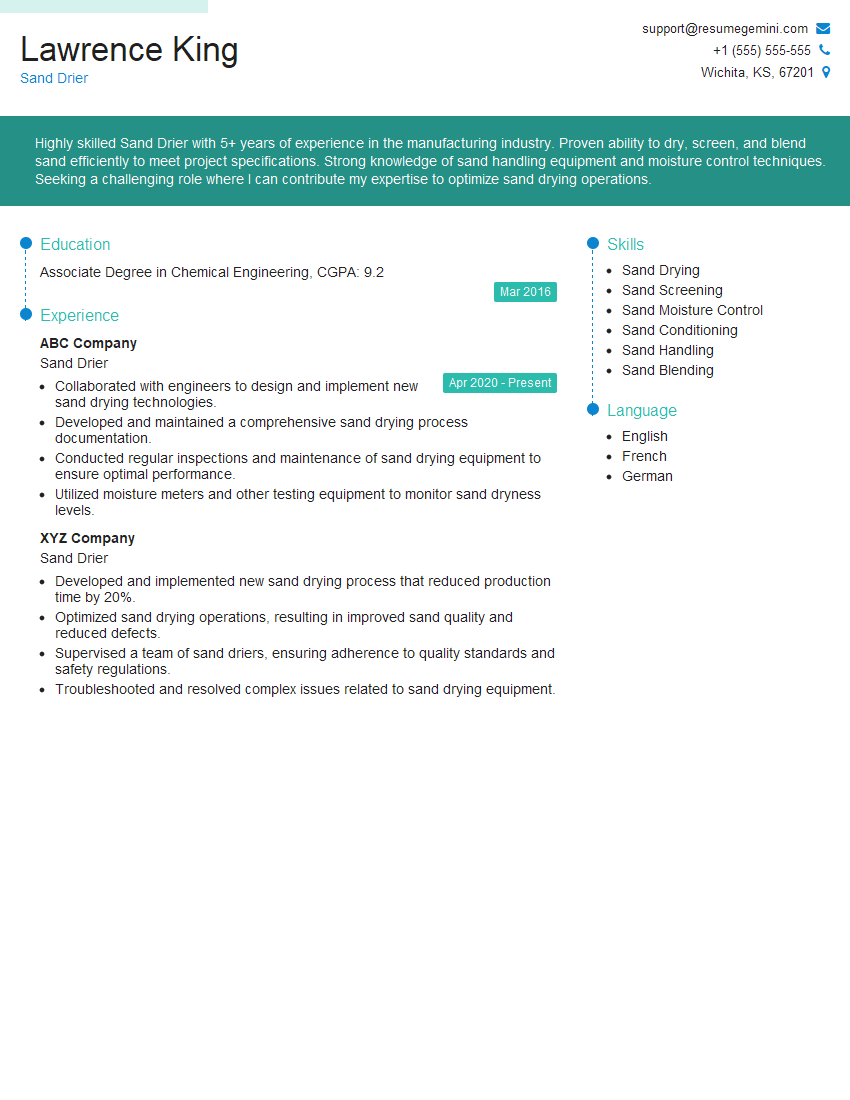

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sand Drier

1. How do you determine the optimal operating temperature for a sand drier?

- Measure the moisture content of the sand to determine the required temperature.

- Consider the type of sand and its thermal properties.

- Monitor the temperature throughout the drying process to ensure it’s within the desired range.

- Adjust the temperature as necessary to minimize energy consumption while effectively drying the sand.

2. Describe the different types of sand driers and their advantages and disadvantages.

Rotary Dryers

Advantages

- High drying capacity

- Suitable for large volumes of sand

- Continuous operation

Advantages

- High energy consumption

- Can be prone to mechanical breakdown

Fluidized Bed Dryers

Advantages

- Uniform drying

- Low energy consumption

- Compact design

Advantages

- Limited capacity

- Not suitable for all types of sand

3. What are the critical factors to consider when designing a sand drier?

- Material moisture content

- Required drying temperature

- Type of heating source

- Throughput rate

- Space constraints

- Energy efficiency

4. How do you ensure the efficient operation of a sand drier?

- Regular maintenance and inspection

- Monitoring of temperature and moisture levels

- Optimization of airflow and heating systems

- Training of operators on proper operating procedures

- Use of energy-saving measures

5. How do you troubleshoot common problems encountered in sand drier operations?

- Clogged nozzles – Check for blockages in the nozzles and clean them accordingly.

- Uneven drying – Adjust the airflow and temperature distribution inside the drier.

- Overheating – Reduce the operating temperature or increase airflow.

- Mechanical issues – Inspect and repair any mechanical components that are causing problems.

- High energy consumption – Optimize the operation parameters to reduce energy usage.

6. What are the latest advancements in sand drier technology?

- Energy-efficient designs

- Use of advanced control systems

- Integration of sensors and IoT devices

- Improved materials for wear resistance

- Focus on environmental sustainability

7. How do you stay updated on the latest sand drier technologies and industry trends?

- Attend industry conferences and exhibitions

- Read technical journals and research papers

- Engage with industry experts and suppliers

- Participate in online forums and discussion groups

- Conduct market research and analysis

8. Describe your experience in designing and implementing sand drying systems.

I have designed and implemented several sand drying systems for various industries, including foundries, construction companies, and mining operations. My responsibilities included:

- Conducting thorough analysis of material properties and drying requirements

- Selecting and configuring appropriate sand drying equipment

- Developing control systems to optimize drying efficiency and energy consumption

- Ensuring compliance with safety and environmental regulations

- Providing technical support and training to operators

9. What software tools do you use for sand drier design and analysis?

- CFD modeling software for airflow and temperature distribution analysis

- Heat transfer simulation software for energy efficiency optimization

- 3D CAD software for equipment design and integration

- Control system design and simulation tools

- Data acquisition and analysis software

10. How do you approach the design of a sand drier for a new application or industry?

When designing a sand drier for a new application or industry, I follow a systematic approach that includes:

- Understanding the specific requirements of the application, including material properties, drying temperature, and throughput rate.

- Researching and evaluating different sand drier technologies and configurations to determine the most appropriate solution.

- Conducting pilot tests or simulations to validate the design and optimize operating parameters.

- Developing a detailed design plan that includes equipment specifications, control system architecture, and installation guidelines.

- Working closely with the customer throughout the design and implementation process to ensure their satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sand Drier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sand Drier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sand Driers are responsible for operating and maintaining sand drying equipment in industrial settings, ensuring that sand used in various processes is properly dried and meets specifications. Key job responsibilities include:

1. Equipment Operation

Operate sand drying equipment according to established procedures.

- Monitor equipment settings and make adjustments as needed.

- Maintain equipment to ensure optimal performance and prevent breakdowns.

2. Sand Drying

Dry sand to the required moisture content.

- Control temperature and airflow within the drying chamber.

- Monitor sand moisture levels and make adjustments as necessary.

3. Quality Control

Ensure the dried sand meets quality specifications.

- Perform quality checks on dried sand samples.

- Report any deviations from specifications to supervisors.

4. Equipment Maintenance

Maintain and repair sand drying equipment.

- Perform routine maintenance checks and inspections.

- Identify and resolve equipment issues promptly.

5. Safety and Compliance

Adhere to safety protocols and industry regulations.

- Wear appropriate safety gear.

- Follow lockout/tagout procedures.

Interview Tips

Preparing for a Sand Drier interview requires a comprehensive understanding of the role and the industry. Here are some tips to help candidates ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s business, products, and industry trends. This knowledge will help you tailor your answers and demonstrate your interest in the position.

- Visit the company website.

- Read industry publications and news articles.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to sand drying equipment, quality control, equipment maintenance, and safety procedures. Use the STAR (Situation, Task, Action, Result) method to structure your answers.

- Describe a time you resolved a problem with sand drying equipment.

- Explain your approach to ensuring the dried sand meets specifications.

- What safety precautions do you take when operating sand drying equipment?

3. Highlight Relevant Skills and Experience

Emphasize your technical skills in operating and maintaining sand drying equipment. Highlight your experience in quality control and safety protocols.

- Quantify your accomplishments using specific examples.

- Be specific about your role in sand drying operations.

4. Demonstrate Problem-Solving Abilities

Sand Driers often encounter unexpected challenges. Share examples of how you have solved problems and overcome obstacles in previous roles.

- Describe a situation where you identified and resolved a sand drying issue.

- Explain how you handled equipment breakdowns or maintenance emergencies.

5. Enthusiasm and Professionalism

Demonstrate your enthusiasm for the role and the industry. Maintain a professional demeanor and dress appropriately for the interview.

- Ask thoughtful questions to show your interest and engagement.

- Be polite and respectful to everyone you meet during the interview process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sand Drier interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!