Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sand Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

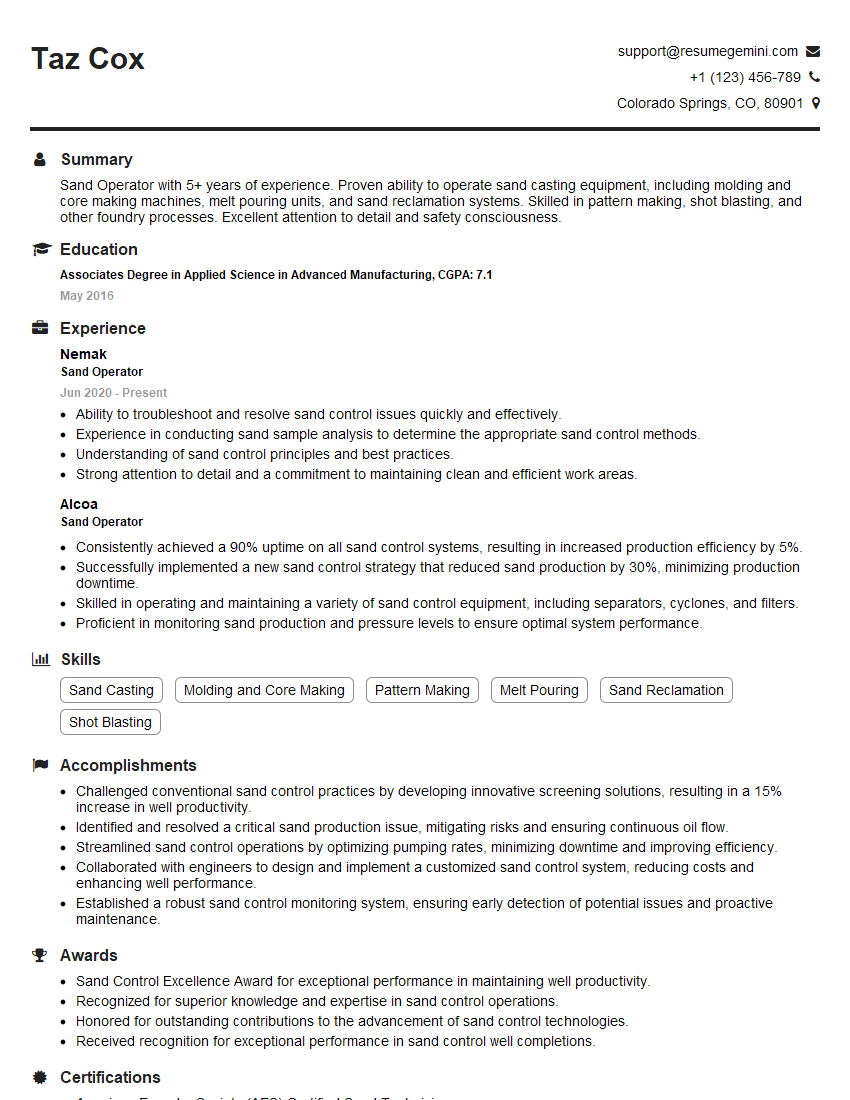

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sand Operator

1. Describe the process of sand handling in a water treatment plant?

Sand handling in a water treatment plant involves several key steps:

- Sand Extraction: Sand is typically obtained from a quarry or a riverbed and transported to the water treatment plant.

- Screening and Washing: The sand is screened to remove larger debris and then washed to remove impurities such as silt and clay.

- Grading: The washed sand is graded according to its size and uniformity to ensure optimal performance in the filters.

- Sand Loading: The graded sand is loaded into the sand filters, where it serves as a filtration media.

- Sand Backwashing: Periodically, the filters are backwashed to remove accumulated contaminants and maintain the sand’s effectiveness.

- Sand Disposal: Spent sand is typically disposed of in landfills or used for other purposes such as construction or landscaping.

2. What are the different types of sand filters used in water treatment?

Sand filters in water treatment are primarily classified into two types:

Rapid Gravity Filters

- Use sand as the primary filtration media.

- Operated under gravity, with water flowing downward through the sand bed.

- Suitable for treating surface water with moderate turbidity levels.

Pressure Filters

- Enclosed in a pressurized vessel.

- Can operate at higher flow rates and pressures.

- Often used for treating groundwater or pretreated surface water with low turbidity levels.

3. What are the key factors to consider when selecting sand for water filtration?

The following factors are important when selecting sand for water filtration:

- Grain Size: Sand size should be uniform and within a specific range to achieve optimal filtration efficiency.

- Shape: Rounded sand particles are preferred to avoid clogging and improve filtration performance.

- Porosity: Sand with high porosity allows for good water flow and efficient removal of contaminants.

- Density: Sand should have a density that allows for effective backwashing and prevents settling.

- Chemical Inertness: The sand should be chemically inert to avoid reactions with the treated water.

4. How do you monitor and maintain the performance of sand filters?

Monitoring and maintaining sand filters involves regular tasks such as:

- Pressure Monitoring: Monitoring pressure gauges to ensure proper flow rates and identify potential clogging.

- Turbidity Monitoring: Measuring the turbidity of the filtered water to assess the filter’s efficiency.

- Backwashing: Performing regular backwashing cycles to remove accumulated contaminants and restore sand bed porosity.

- Sand Sampling and Analysis: Periodically taking sand samples for analysis to evaluate its condition and make necessary adjustments.

- Routine Inspections: Conducting regular visual inspections to check for leaks or other issues.

5. What are the common problems encountered in sand filtration and how do you troubleshoot them?

Common problems in sand filtration include:

- Clogging: Caused by excessive accumulation of contaminants, leading to reduced flow rates and increased pressure drop. Can be addressed through backwashing or sand replacement.

- Mud Balls: Formation of agglomerated particles within the sand bed, resulting in channeling and reduced filtration efficiency. Can be prevented by proper coagulation and flocculation prior to filtration.

- Sand Loss: Attributed to backwashing at excessive rates or sand bed expansion due to air entrainment. Can be rectified by adjusting backwashing parameters or using air release valves.

- Biological Growth: Proliferation of microorganisms on the sand bed, causing clogging and reduced filter performance. Can be controlled by regular disinfection or chlorination.

6. Describe your experience in operating and maintaining sand filters.

In my previous role as a Water Treatment Operator, I was responsible for the operation and maintenance of multiple sand filters. My duties included:

- Monitoring filter performance through pressure gauges and turbidity measurements.

- Performing backwashing cycles according to established schedules.

- Sampling and analyzing sand samples to assess its condition and identify any issues.

- Troubleshooting and resolving common problems related to sand filtration.

- Maintaining accurate records of filter operations and maintenance activities.

7. What safety precautions should be taken when working with sand filters?

When working with sand filters, it is essential to follow these safety precautions:

- Wear appropriate PPE: Use gloves, safety glasses, and a respirator to protect against dust and chemicals.

- Secure filter covers: Ensure filter covers are securely fastened to prevent sudden release of pressure.

- Avoid confined spaces: Do not enter confined spaces such as filter vessels without proper ventilation and safety measures.

- Follow lockout/tagout procedures: Isolate and de-energize equipment before performing maintenance or repairs.

- Be aware of potential hazards: Watch for slippery surfaces, tripping hazards, and potential chemical spills.

8. How do you stay up-to-date on industry best practices and advancements in sand filtration?

To stay current on industry best practices and advancements in sand filtration, I engage in the following activities:

- Attend industry conferences and workshops: Participate in events organized by professional organizations to learn about new technologies and research.

- Read technical journals and publications: Stay informed about the latest advancements by reviewing industry literature.

- Network with other professionals: Connect with peers and experts in the field to exchange knowledge and discuss best practices.

- Participate in online forums and discussion groups: Engage in online discussions to stay abreast of industry trends and share experiences.

9. Describe a situation where you encountered a challenging issue related to sand filtration and how you resolved it.

In my previous role, I encountered an issue with excessive pressure drop across a sand filter. After troubleshooting, I identified that the sand bed had become compacted due to inadequate backwashing. To resolve this issue, I adjusted the backwashing parameters, increasing the flow rate and duration. This restored the filter’s performance to normal levels and prevented further issues.

10. How do you handle working in a team environment and collaborate with colleagues?

I am a team-oriented individual with excellent communication and collaboration skills. In my previous role, I worked closely with a team of operators to ensure the smooth operation and maintenance of the water treatment plant. I actively participated in discussions, shared knowledge, and supported my colleagues whenever needed. I am proficient in using various communication tools and platforms to stay connected and coordinate effectively.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sand Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sand Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sand Operators are responsible for overseeing the proper operation and maintenance of sand control equipment in oil and gas production facilities. Their primary goal is to ensure the efficient and safe removal of sand and other particles from produced fluids, which helps to prevent damage to equipment and maximize production.

1. Monitor and Control Sand Control Equipment

Sand Operators are responsible for monitoring and controlling a variety of sand control equipment, including cyclones, hydrocyclones, and sand filters. They must ensure that these devices are operating properly and that they are effectively removing sand and other particles from the produced fluids.

- Inspect and maintain sand control equipment

- Monitor pressure and flow rates

- Adjust equipment settings as needed

2. Maintain Records and Prepare Reports

Sand Operators are responsible for maintaining accurate records of their activities and for preparing reports on the performance of the sand control equipment. These records and reports are essential for tracking the performance of the equipment and for identifying potential problems.

- Record equipment readings and maintenance activities

- Prepare reports on equipment performance

- Review and analyze data to identify trends and potential problems

3. Troubleshoot and Repair Equipment

Sand Operators are responsible for troubleshooting and repairing sand control equipment when necessary. They must be able to identify the source of a problem and take steps to fix it quickly and efficiently.

- Identify and diagnose equipment problems

- Make repairs to equipment

- Coordinate with other personnel to resolve complex issues

4. Work Safely and Follow Procedures

Sand Operators must always work safely and follow established procedures. They must be aware of the potential hazards associated with their work and take steps to minimize the risks.

- Follow safety procedures and regulations

- Wear appropriate personal protective equipment

- Be aware of potential hazards and take steps to minimize risks

Interview Tips

Here are some tips to help you ace your interview for a Sand Operator position:

1. Research the Company and the Position

Before you go on your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and to tailor your answers to the specific requirements of the position.

- Visit the company’s website

- Read industry news and articles

- Talk to people who work in the industry

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Prepare a brief introduction about yourself

- Highlight your skills and experience that are relevant to the position

- Explain why you are interested in the company and the position

3. Be Prepared to Talk About Your Experience

The interviewer will likely ask you about your experience in the oil and gas industry. Be prepared to talk about your experience in detail, including your responsibilities, accomplishments, and any challenges you have faced.

- Quantify your accomplishments using specific numbers and examples

- Highlight your ability to work independently and as part of a team

- Discuss any challenges you have faced and how you overcame them

4. Be Enthusiastic and Professional

Make sure to be enthusiastic and professional throughout your interview. Dress appropriately, arrive on time, and be polite to everyone you meet. Your demeanor will make a positive impression on the interviewer and will increase your chances of getting the job.

- Dress professionally and arrive on time for your interview

- Be polite and respectful to everyone you meet

- Maintain eye contact and speak clearly and confidently

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Sand Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Sand Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.