Are you gearing up for an interview for a Sandblast Carver position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Sandblast Carver and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

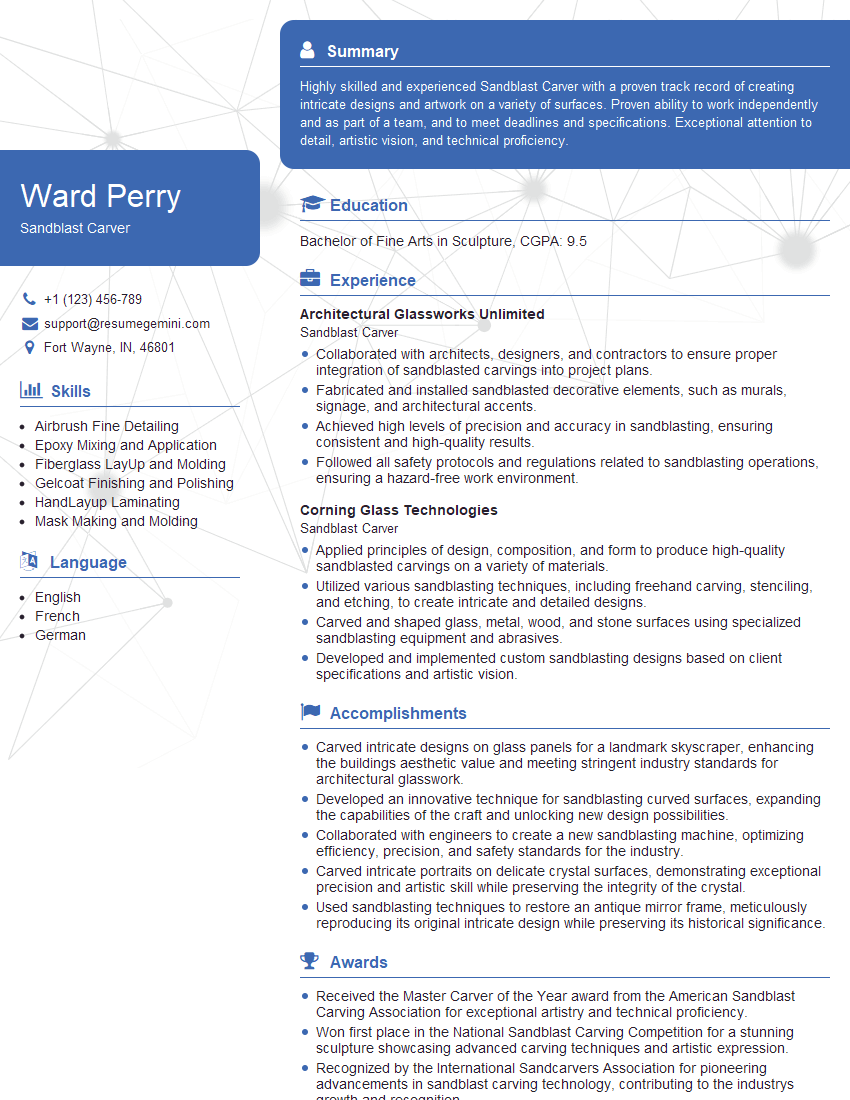

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sandblast Carver

1. How do you select the appropriate blast media for a specific project?

- Consider the substrate material and its surface condition.

- Determine the desired surface finish and the level of contamination.

- Select the blast media type (e.g., sand, garnet, aluminum oxide) and size (grit) based on the substrate and desired outcome.

- Consult with suppliers or industry experts for recommendations based on the specific project requirements.

2. Describe the different types of sandblast nozzles and their applications.

Venturi Nozzles

- Produce a high-velocity, concentrated jet stream.

- Used for precise cutting, shaping, and surface cleaning.

Nozzle Extensions

- Increase the working distance and reduce blast media consumption.

- Useful for overhead or hard-to-reach areas.

Wide-Angle Nozzles

- Create a broad, fan-shaped spray pattern.

- Suitable for large surface cleaning and coating removal.

3. What are the safety precautions you follow during sandblasting operations?

- Wear appropriate protective gear (respirator, gloves, eye protection).

- Keep the blast area well-ventilated and isolate from others.

- Inspect equipment and hoses regularly for damage.

- Handle and dispose of blast media safely to prevent dust inhalation.

- Follow proper grounding and electrical safety protocols.

4. What are the common troubleshooting techniques for malfunctioning sandblasting equipment?

- Check for clogged nozzles or hoses.

- Inspect the air compressor for leaks or insufficient pressure.

- Verify the power supply and electrical connections.

- Examine the blast media for moisture or contamination.

- Contact the equipment manufacturer for technical support.

5. Describe the steps involved in preparing a surface for sandblasting.

- Remove any loose debris or contaminants from the surface.

- Protect non-blastable areas with masking tape or covers.

- Test a small area to determine the optimal blast parameters.

- Set up the blasting equipment and adjust the blast media flow and pressure.

- Follow a systematic blasting pattern to ensure even coverage.

6. What are the different techniques used to achieve various surface finishes with sandblasting?

- Varying the blast media type and size to create different textures.

- Adjusting the blast pressure and distance to control the intensity and depth of the finish.

- Using multiple passes or different nozzle angles to achieve specific patterns or effects.

- Combining sandblasting with other surface preparation techniques (e.g., grinding, polishing) to enhance the final finish.

7. How do you determine the appropriate air pressure and blast media flow rate for sandblasting operations?

- Consider the substrate material, surface condition, and desired outcome.

- Refer to manufacturer’s specifications for recommended pressure and flow rate ranges.

- Perform test blasts on a small area to optimize the parameters.

- Adjust the settings to achieve the desired balance between cleaning efficiency and surface finish.

8. What is the difference between wet and dry sandblasting, and when would you use each method?

Wet Sandblasting

- Uses a water-abrasive mixture to reduce dust and improve cleaning efficiency.

- Suitable for cleaning delicate surfaces or removing stubborn contaminants.

Dry Sandblasting

- Uses abrasive media without water.

- More aggressive and faster than wet sandblasting.

- Ideal for heavy-duty cleaning and surface preparation.

9. How do you ensure the quality of your sandblasting work and meet customer requirements?

- Establish clear communication and expectations with customers.

- Inspect the surface before and after blasting to confirm the desired results.

- Use high-quality equipment and maintain it regularly.

- Follow industry best practices and safety guidelines.

- Provide documentation and certification of the completed work.

10. Can you describe your experience in using different types of sandblasting equipment and techniques?

- List the specific equipment and techniques you have used.

- Provide examples of projects where you successfully applied these skills.

- Highlight any unique challenges you encountered and how you overcame them.

- Quantify your results, if possible, to demonstrate your proficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sandblast Carver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sandblast Carver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sandblast carvers are skilled artisans who use specialized techniques to create intricate designs on glass, metal, and other surfaces. They apply specialized knowledge of different sandblasting techniques and equipment to produce visually appealing and durable works of art. Their primary responsibilities include:

1. Design and Layout

They collaborate with designers or customers to understand design requirements, prepare sketches, and create detailed patterns for sandblasting.

- Interpret design specifications and transfer them accurately onto the designated surface.

- Use software or hand-drawn techniques to create stencils or templates for sandblasting.

2. Surface Preparation

Meticulously prepare the surface to ensure proper adhesion and prevent damage during the sandblasting process.

- Clean and degrease the surface to remove any contaminants.

- Apply protective coatings or masking materials to safeguard areas not intended for sandblasting.

3. Sandblasting

Operate sandblasting equipment to create precise and detailed designs on the surface. They adjust variables such as abrasive type, pressure, and nozzle distance to achieve desired effects.

- Select appropriate abrasives (e.g., sand, glass beads, aluminum oxide) based on the surface material and desired finish.

- Control the sandblasting process to achieve specific textures, depths, and patterns.

4. Finishing

Complete the sandblasted artwork by removing stencils, cleaning the surface, and applying protective coatings or sealant to enhance durability.

- Remove stencils or templates carefully to reveal the finished design.

- Clean the sandblasted surface to remove any residual abrasive or dust.

- Apply a protective coating or sealant to preserve the artwork and prevent deterioration.

Interview Tips

To ace the interview for a Sandblast Carver position, it is crucial to prepare thoroughly and demonstrate your skills and knowledge. Here are some tips and hacks to guide you:

1. Research the Company and Industry

Before the interview, take time to research the company you are applying to and the sandblasting industry. This will show the interviewer that you are genuinely interested in the position and have a basic understanding of the company’s operations.

- Visit the company’s website and social media pages to learn about their products, services, and company culture.

- Read industry-related articles, blogs, and publications to stay up-to-date with the latest techniques and trends.

2. Showcase Your Portfolio

If you have a portfolio of your sandblasting work, bring it to the interview or prepare a digital presentation to showcase your skills. This is an excellent opportunity to demonstrate your artistic abilities, attention to detail, and technical expertise.

- Present a range of samples that highlight your versatility and mastery of different sandblasting techniques.

- Provide clear explanations of your design process, the materials used, and the challenges you encountered.

3. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivations. Take time to formulate thoughtful and concise answers that demonstrate your knowledge and enthusiasm for sandblasting.

- Why are you interested in this Sandblast Carver position?

- Describe your experience with different types of sandblasting techniques.

- How do you ensure precision and attention to detail in your work?

- What are some of the challenges you have faced in sandblasting, and how did you overcome them?

4. Ask Insightful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare a few specific questions to ask the interviewer about the company, the position, or the sandblasting industry.

- What are the company’s current and future projects that involve sandblasting?

- What opportunities are there for professional development and growth within the company?

- Can you provide more information about the company’s safety protocols related to sandblasting?

5. Dress Professionally and Be Punctual

Make a positive first impression by dressing professionally and arriving on time for the interview. Your attire should be appropriate for the office environment and convey your respect for the company and the position.

- Choose clothing that is clean, pressed, and fits well.

- Avoid wearing excessive jewelry or bright colors.

- Arrive at the interview location at least 10 minutes early to allow for any unexpected delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sandblast Carver interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!