Feeling lost in a sea of interview questions? Landed that dream interview for Sandblast Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Sandblast Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

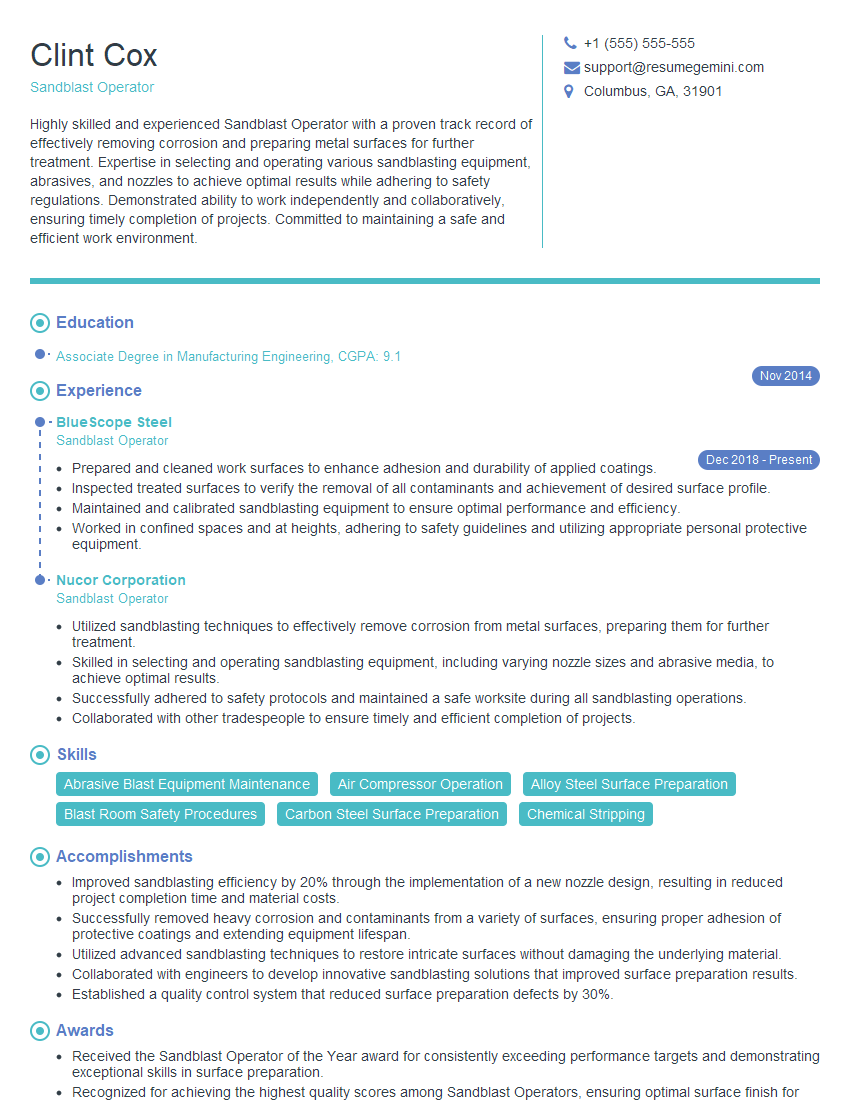

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sandblast Operator

1. Describe the step-by-step process for sandblasting a metal surface.

The step-by-step process for sandblasting a metal surface includes:

- Preparing the surface by removing any dirt, grease, or other contaminants.

- Masking off any areas that should not be sandblasted.

- Selecting the appropriate abrasive material and nozzle size for the job.

- Setting up the sandblasting equipment and adjusting the pressure and flow rate.

- Holding the nozzle at a 45-degree angle to the surface and moving it back and forth in a consistent pattern.

- Inspecting the surface after sandblasting to ensure that all contaminants have been removed.

2. What are the different types of sandblasting abrasives and when should each type be used?

Types of Sandblasting Abrasives

- Sand: Inexpensive and widely available, but can be dusty and can cause silicosis.

- Glass beads: More expensive than sand, but less dusty and does not cause silicosis.

- Aluminum oxide: A hard abrasive that is suitable for removing heavy rust and scale.

- Soda: A soft abrasive that is used for cleaning delicate surfaces.

When to Use Each Type of Abrasive

- Sand: Suitable for general-purpose sandblasting, such as removing rust and paint.

- Glass beads: Used for cleaning delicate surfaces, such as fiberglass and aluminum.

- Aluminum oxide: Used for removing heavy rust and scale, such as from metal castings.

- Soda: Used for cleaning delicate surfaces, such as wood and stone.

3. What are the safety precautions that must be taken when sandblasting?

The safety precautions that must be taken when sandblasting include:

- Wearing appropriate personal protective equipment (PPE), including a respirator, gloves, eye protection, and hearing protection.

- Ensuring that the sandblasting area is well-ventilated.

- Using a sandblasting cabinet or enclosure to contain the dust and debris.

- Never sandblasting in the direction of people or animals.

- Inspecting the sandblasting equipment regularly and making repairs as needed.

4. What are the different surface finishes that can be achieved with sandblasting?

The different surface finishes that can be achieved with sandblasting include:

- Rough finish: This is the most common finish, and it is used to remove rust, paint, and other contaminants.

- Smooth finish: This finish is used to create a smooth, even surface on metal.

- Matte finish: This finish is used to create a dull, non-reflective surface.

- Gloss finish: This finish is used to create a shiny, reflective surface.

5. What are some of the common applications for sandblasting?

Some of the common applications for sandblasting include:

- Surface preparation: Sandblasting is used to remove rust, paint, and other contaminants from surfaces prior to painting, coating, or welding.

- Cleaning: Sandblasting is used to clean dirty or stained surfaces, such as buildings, bridges, and vehicles.

- De-scaling: Sandblasting is used to remove scale from metal surfaces, such as castings and forgings.

- Etching: Sandblasting is used to create decorative or functional patterns on surfaces, such as glass and metal.

6. What are the advantages of using sandblasting?

The advantages of using sandblasting include:

- Fast and efficient: Sandblasting is a fast and efficient way to remove rust, paint, and other contaminants from surfaces.

- Versatile: Sandblasting can be used on a variety of surfaces, including metal, wood, concrete, and glass.

- Cost-effective: Sandblasting is a relatively cost-effective way to clean and prepare surfaces.

- Environmentally friendly: Sandblasting does not produce any harmful emissions.

7. What are the disadvantages of using sandblasting?

The disadvantages of using sandblasting include:

- Can be dusty: Sandblasting can generate a lot of dust, which can be a health hazard.

- Can be noisy: Sandblasting can be noisy, which can be a nuisance to nearby residents or businesses.

- Can damage surfaces: Sandblasting can damage delicate surfaces, such as glass and wood, if it is not done properly.

8. How do you determine the correct nozzle size and pressure for a sandblasting job?

The correct nozzle size and pressure for a sandblasting job depends on the material being blasted, the desired finish, and the size of the surface area being blasted.

In general, a larger nozzle size will produce a faster and more aggressive blast, while a smaller nozzle size will produce a slower and more controlled blast.

The correct pressure will depend on the material being blasted and the desired finish.

9. What are some tips for sandblasting safely and effectively?

Some tips for sandblasting safely and effectively include:

- Wear appropriate personal protective equipment (PPE), including a respirator, gloves, eye protection, and hearing protection.

- Ensure that the sandblasting area is well-ventilated.

- Use a sandblasting cabinet or enclosure to contain the dust and debris.

- Never sandblast in the direction of people or animals.

- Inspect the sandblasting equipment regularly and make repairs as needed.

- Follow the manufacturer’s instructions for the sandblasting equipment.

10. What is the difference between sandblasting and soda blasting?

Sandblasting and soda blasting are both abrasive blasting processes, but they use different abrasives.

Sandblasting uses sand as the abrasive, while soda blasting uses baking soda.

Soda blasting is less abrasive than sandblasting, so it is often used on delicate surfaces, such as wood, glass, and fiberglass.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sandblast Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sandblast Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sandblast Operators are responsible for preparing, protecting, and cleaning surfaces using abrasive blasting equipment. They must be able to operate and maintain equipment, as well as follow safety procedures. Some common responsibilities of Sandblast Operators include:

1. Preparing Surfaces

Sandblast Operators prepare surfaces for coating or finishing by removing rust, paint, or other contaminants. They may also use sandblasting to roughen surfaces to improve adhesion.

- Selecting the appropriate abrasive material

- Adjusting the equipment to the correct settings

- Protecting surrounding areas from abrasive materials

2. Operating Sandblasting Equipment

Sandblast Operators use a variety of sandblasting equipment, including portable units and large stationary units. They must be able to operate the equipment safely and efficiently.

- Wearing appropriate personal protective equipment

- Following all safety regulations

- Monitoring the equipment for any problems

3. Maintaining Equipment

Sandblast Operators are responsible for maintaining their equipment in good working condition. They must perform regular inspections and maintenance tasks, such as cleaning and lubricating the equipment.

- Inspecting hoses and nozzles for damage

- Replacing worn or damaged parts

- Lubricating moving parts

4. Cleaning Up

Sandblast Operators are responsible for cleaning up after themselves. They must remove all abrasive materials and debris from the work area. They must also dispose of hazardous materials properly.

- Sweeping or vacuuming up abrasive materials

- Disposing of hazardous materials according to regulations

- Cleaning equipment and work area

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips for Sandblast Operator interviews:

1. Research the Company

Before the interview, take some time to research the company you are applying to. This will give you a better understanding of their business, their values, and their culture. You can also find out more about the specific position you are applying for.

- Visit the company’s website

- Read articles about the company

- Talk to people who work for the company

2. Practice Your Answers

Once you have researched the company, it is a good idea to practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Think about your strengths and weaknesses

- Prepare answers to common interview questions

- Practice answering questions out loud

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, conservative clothing that fits well.

- Wear a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Wear comfortable shoes

4. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and open about your experience

- Show the interviewer your passion for sandblasting

- Be confident in your abilities

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sandblast Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.