Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sandblaster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

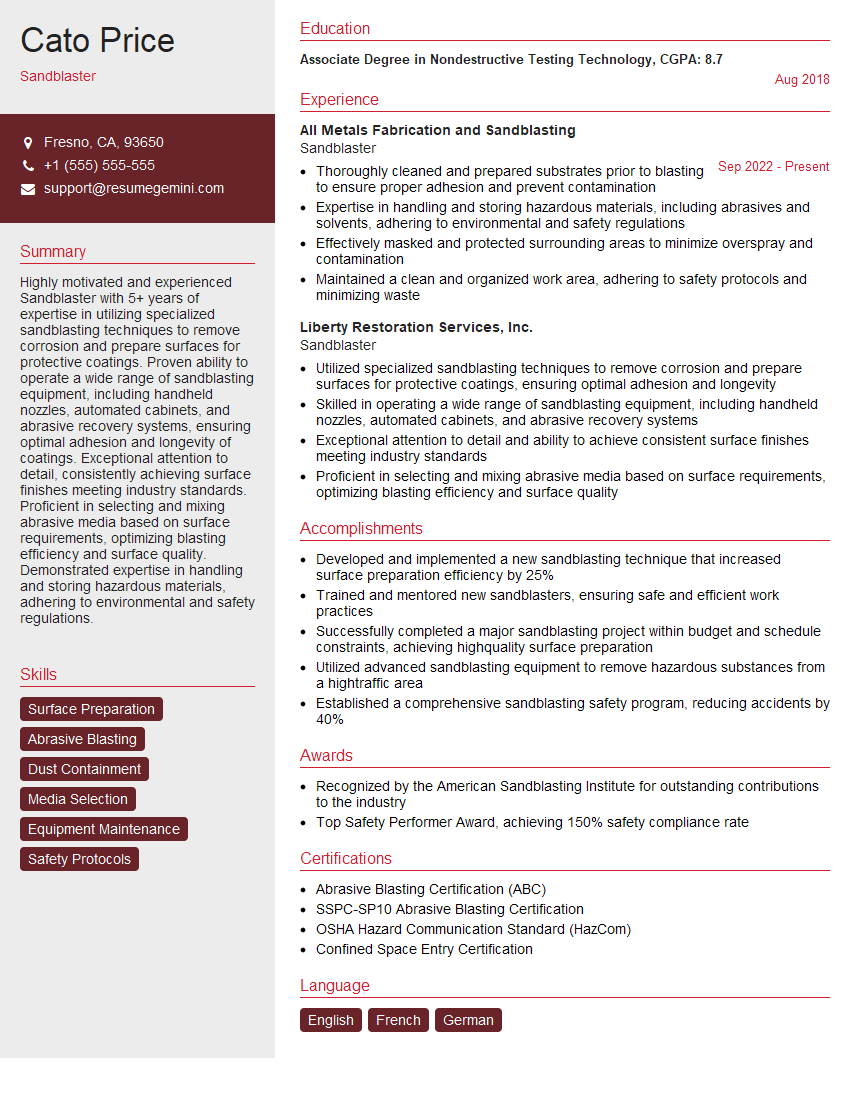

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sandblaster

1. What are the different types of sandblasting equipment and when would you use each type?

There are three main types of sandblasting equipment: pressure-fed, suction-fed, and centrifugal wheel. Pressure-fed sandblasters are the most common type and are used for a wide variety of applications, from small projects to large industrial jobs. Suction-fed sandblasters are less common and are typically used for smaller projects, such as cleaning delicate surfaces. Centrifugal wheel sandblasters are the most powerful type of sandblaster and are used for large industrial projects, such as cleaning bridges and buildings.

2. What are the different types of abrasives used in sandblasting and what are the pros and cons of each?

- Sand is the most common abrasive used in sandblasting and is a good choice for most applications. It is relatively inexpensive and readily available, and it can be used to remove a variety of coatings, including paint, rust, and dirt.

- Glass beads are a more expensive abrasive than sand, but they are less likely to damage delicate surfaces. They are often used for cleaning fiberglass, metal, and wood.

- Soda ash is a non-abrasive cleaning agent that is often used to clean delicate surfaces, such as glass and marble. It is also a good choice for removing graffiti.

3. What are the safety precautions that should be taken when sandblasting?

- Wear appropriate protective clothing, including a respirator, gloves, and safety glasses.

- Work in a well-ventilated area.

- Keep the sandblaster nozzle at a safe distance from the surface being blasted.

- Never point the sandblaster nozzle at yourself or anyone else.

- Inspect the sandblaster equipment regularly and make sure it is in good working condition.

4. What are the different surface preparation methods that can be used prior to sandblasting?

- Mechanical cleaning – this involves using a wire brush, grinder, or other tool to remove loose paint, rust, and dirt.

- Chemical cleaning – this involves using a solvent or other chemical to remove grease, oil, and other contaminants.

- Abrasive blasting – this involves using a sandblaster to remove paint, rust, and dirt.

5. What are the different types of coatings that can be applied after sandblasting?

- Paint – this is the most common type of coating applied after sandblasting and is available in a wide variety of colors and finishes.

- Powder coating – this is a durable, long-lasting coating that is applied using a powder that is electrostatically charged and sprayed onto the surface being coated.

- Galvanizing – this is a process of applying a zinc coating to a metal surface to protect it from corrosion.

- Anodizing – this is a process of applying a protective oxide layer to a metal surface to increase its corrosion resistance and wear resistance.

6. What are the different factors that affect the cost of sandblasting?

- The size of the surface being blasted

- The type of abrasive being used

- The type of coating being applied

- The location of the project

- The experience of the sandblaster

7. What are the benefits of sandblasting?

- Sandblasting can remove a variety of coatings, including paint, rust, and dirt.

- Sandblasting can prepare a surface for painting or other coatings.

- Sandblasting can improve the appearance of a surface.

- Sandblasting can increase the lifespan of a surface.

8. What are the disadvantages of sandblasting?

- Sandblasting can be a noisy and messy process.

- Sandblasting can damage delicate surfaces.

- Sandblasting can create dust that can be harmful to health.

- Sandblasting can be expensive.

9. What are the different types of sandblasting nozzles and what are the pros and cons of each?

- Round nozzles – these are the most common type of sandblasting nozzle and are used for a wide variety of applications. They produce a concentrated stream of abrasive that can be used to remove paint, rust, and dirt.

- Flat nozzles – these nozzles produce a wider stream of abrasive that is less concentrated than the stream produced by a round nozzle. They are often used for cleaning large, flat surfaces.

- Venturi nozzles – these nozzles produce a high-velocity stream of abrasive that is ideal for removing tough coatings, such as thick paint or rust.

10. What are the different types of sandblasting cabinets and what are the pros and cons of each?

- Open-front cabinets – these cabinets are open on the front, allowing for easy access to the workpiece. They are often used for small to medium-sized parts.

- Closed-front cabinets – these cabinets are enclosed on all sides, except for a small opening for the sandblaster nozzle. They are often used for large parts or for parts that need to be protected from dust.

- Down-draft cabinets – these cabinets have a down-draft system that helps to remove dust and debris from the work area. They are often used for blasting small parts or for parts that need to be protected from dust.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sandblaster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sandblaster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Sandblaster, you will be responsible for a wide range of tasks, including:

1. Surface Preparation

Inspect surfaces and identify areas requiring treatment

- Clean and prepare surfaces for painting, coating, or other treatments

- Remove rust, paint, graffiti, or other contaminants

2. Sandblasting Techniques

Select appropriate abrasive media and blasting equipment

- Operate sandblasting equipment safely and effectively

- Use various nozzles and attachments to achieve desired surface finish

3. Safety Management

Maintain a safe work environment

- Wear appropriate protective gear and clothing

- Follow safety protocols and procedures

4. Maintenance and Repair

Perform basic maintenance and repairs on sandblasting equipment

- Clean and replace nozzles, hoses, and other components

- Identify and troubleshoot mechanical issues

Interview Tips

To ace your Sandblaster interview, you should:

1. Research the Industry and Company

Demonstrate your understanding of the sandblasting industry and the company you are applying to.

- Research different sandblasting techniques and equipment.

- Visit the company’s website to learn about their products and services.

2. Highlight Your Experience and Skills

Emphasize your previous experience in sandblasting or related fields.

- Quantify your achievements and provide specific examples.

- Showcase your proficiency in operating different types of sandblasting equipment.

3. Emphasize Safety Consciousness

Stress your commitment to maintaining a safe work environment.

- Explain your knowledge of safety regulations and protocols.

- Describe your experience in using protective gear and equipment.

4. Prepare for Technical Questions

Be prepared to answer technical questions related to sandblasting.

- Review different abrasive media and their applications.

- Practice demonstrating your proficiency in operating sandblasting equipment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sandblaster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!