Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sandblaster Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

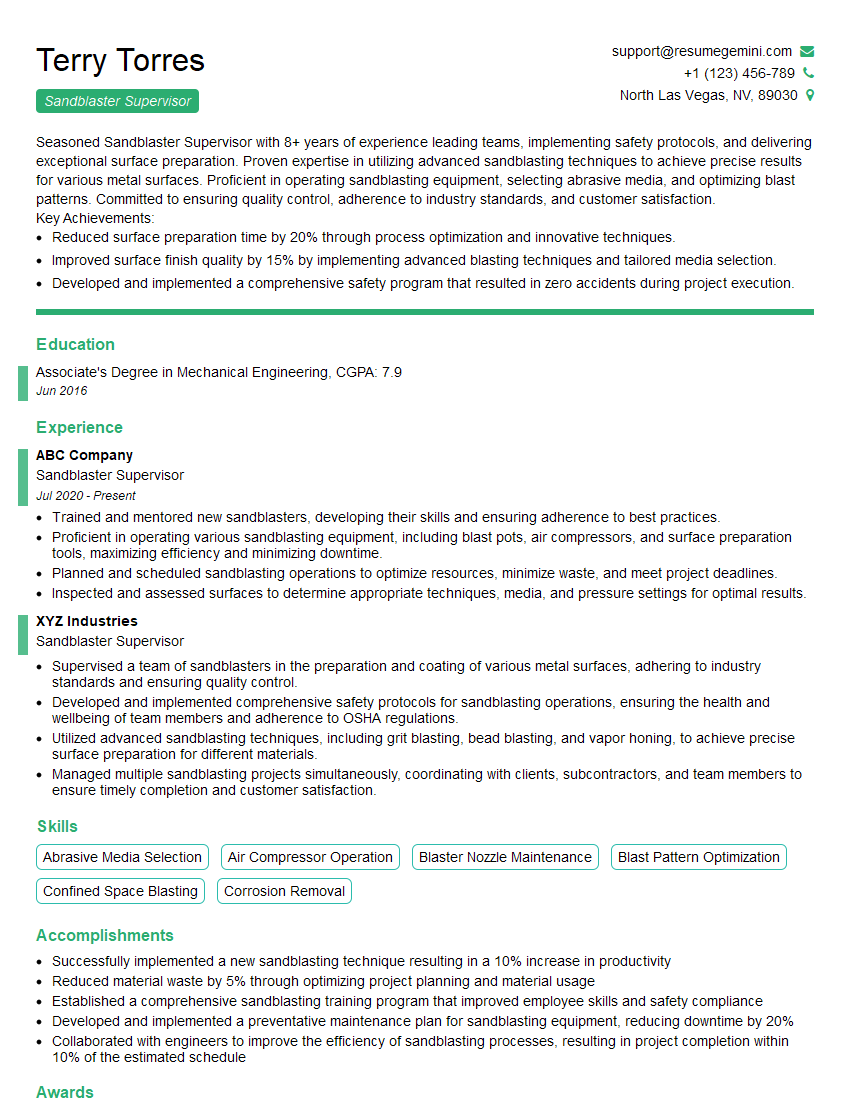

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sandblaster Supervisor

1. Can you describe the different types of sandblasting equipment and their uses?

– Suction-feed or direct pressure-feed blasters use compressed air to pull in dry abrasive material and propel it through the nozzle. – In-line blasters use a venturi system to create a vacuum that draws in abrasive material and propels it through the nozzle. – Wheelblasters use a rotating impeller to propel abrasive material against the surface being cleaned. – Airless blasters use high-pressure water to propel abrasive material against the surface being cleaned.

2. What are the different types of abrasive materials used in sandblasting and their properties?

Abrasive type

- Aluminum oxide: Hard, tough, and long-lasting. Used for general purpose sandblasting.

- Silicon carbide: Harder than aluminum oxide but more brittle. Used for removing heavy rust and scale.

- Glass beads: Softer than aluminum oxide and silicon carbide. Used for cleaning delicate surfaces and removing paint.

- Plastic beads: Even softer than glass beads. Used for cleaning very delicate surfaces and removing paint without damaging the underlying surface.

Abrasive size

- Fine abrasives: Used for delicate work and removing paint. Can leave a smoother surface finish.

- Medium abrasives: Used for general purpose sandblasting. Can remove rust and scale without damaging the underlying surface.

- Coarse abrasives: Used for heavy-duty work and removing thick layers of rust and scale. Can leave a rougher surface finish.

3. What are the safety precautions that must be taken when sandblasting?

- Wear appropriate personal protective equipment (PPE), including a respirator, gloves, eye protection, and hearing protection.

- Ensure that the work area is well-ventilated and free of dust and debris.

- Use a sandblaster that is in good condition and has been properly maintained.

- Follow the manufacturer’s instructions for safe operation of the sandblaster.

- Be aware of the potential hazards of sandblasting, such as silicosis, lead poisoning, and eye injuries.

4. What are the different methods of surface preparation for sandblasting?

- Power tool cleaning: Using power tools like grinders or sanders to remove rust, paint, and other contaminants from the surface.

- Chemical cleaning: Using chemical solutions to dissolve or remove contaminants from the surface.

- Mechanical cleaning: Using brushes, scrapers, or other tools to physically remove contaminants from the surface.

- Flame cleaning: Using a flame to remove organic contaminants from the surface.

5. What are the different types of surface finishes that can be achieved with sandblasting?

- Smooth finish: A smooth, polished finish that is ideal for surfaces that will be painted or coated.

- Matte finish: A slightly rougher finish that is ideal for surfaces that will not be painted or coated.

- Textured finish: A rough finish that is ideal for surfaces that need to be non-slip or have a specific texture.

6. What are the different factors that affect the cost of sandblasting?

- The size of the area to be sandblasted

- The type of surface to be sandblasted

- The thickness of the material to be removed

- The type of abrasive material used

- The cost of labor

7. What are the advantages and disadvantages of sandblasting?

Advantages

- Sandblasting is a very effective way to remove rust, paint, and other contaminants from surfaces.

- Sandblasting can be used on a variety of materials, including metal, concrete, and wood.

- Sandblasting can create a variety of surface finishes, from smooth to textured.

Disadvantages

- Sandblasting can be a noisy and dusty process.

- Sandblasting can be harmful to the environment if the abrasive material is not properly disposed of.

- Sandblasting can be expensive, depending on the size of the area to be sandblasted and the type of surface to be sandblasted.

8. What are some of the common problems that can occur during sandblasting and how can they be prevented?

- Clogging of the nozzle: This can be prevented by using a properly sized nozzle and by keeping the abrasive material dry.

- Warping of the surface: This can be prevented by using a lower pressure setting and by moving the nozzle around constantly.

- Damage to the surface: This can be prevented by using a proper abrasive material and by using a lower pressure setting.

9. What are some of the new technologies that are being used in sandblasting?

- Laser sandblasting: This technology uses a laser to remove contaminants from surfaces. It is more precise and less harmful to the environment than traditional sandblasting.

- Waterjet sandblasting: This technology uses a high-pressure water jet to remove contaminants from surfaces. It is less noisy and dusty than traditional sandblasting.

- Dry ice sandblasting: This technology uses dry ice pellets to remove contaminants from surfaces. It is non-abrasive and does not create any dust.

10. What are the career opportunities for sandblasters?

- Sandblasters can work in a variety of industries, including construction, manufacturing, and automotive repair.

- Sandblasters can start their own businesses or work for a sandblasting company.

- Sandblasters can advance their careers by becoming certified or by taking on supervisory roles.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sandblaster Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sandblaster Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Sandblaster Supervisor oversees and manages the operations of a sandblasting team. Key responsibilities include:

1. Team Management

Lead, train, and motivate a team of sandblasters.

- Assign tasks, set goals, and monitor performance.

- Provide ongoing training and guidance to ensure team proficiency and safety.

2. Project Planning and Execution

Plan and execute sandblasting projects efficiently and effectively.

- Review project specifications and determine the appropriate equipment and techniques.

- Coordinate with other departments, such as engineering and maintenance, to ensure smooth project completion.

3. Quality Control and Safety

Ensure the quality of sandblasting work meets industry standards and safety regulations.

- Inspect finished surfaces for defects and ensure compliance with specifications.

- Implement and enforce safety protocols to protect workers and the environment.

4. Equipment Maintenance and Troubleshooting

Maintain and troubleshoot sandblasting equipment to maximize uptime.

- Perform regular inspections and maintenance to prevent breakdowns.

- Troubleshoot and repair equipment to minimize downtime and costs.

Interview Tips

To ace an interview for a Sandblaster Supervisor position, consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s business, industry trends, and safety regulations.

- Visit the company website, read industry publications, and attend relevant events.

2. Highlight Leadership and Management Skills

Emphasize your ability to lead, motivate, and train a team effectively.

- Provide specific examples of how you have successfully managed people and projects.

- Discuss your strategies for employee development and conflict resolution.

3. Showcase Technical Expertise

Demonstrate a thorough understanding of sandblasting techniques, equipment, and safety protocols.

- Describe the different types of sandblasting equipment and their applications.

- Discuss the safety measures you employ to protect workers and the environment.

4. Prepare for Common Interview Questions

Practice answering common interview questions related to your skills, experience, and motivations.

- Example Outline:

- Tell me about a time you successfully led a team to overcome a challenge.

- Describe your experience with sandblasting equipment and safety regulations.

- How do you stay up-to-date with industry best practices in sandblasting?

Next Step:

Now that you’re armed with the knowledge of Sandblaster Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Sandblaster Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini