Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Sanding Machine Buffer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Sanding Machine Buffer so you can tailor your answers to impress potential employers.

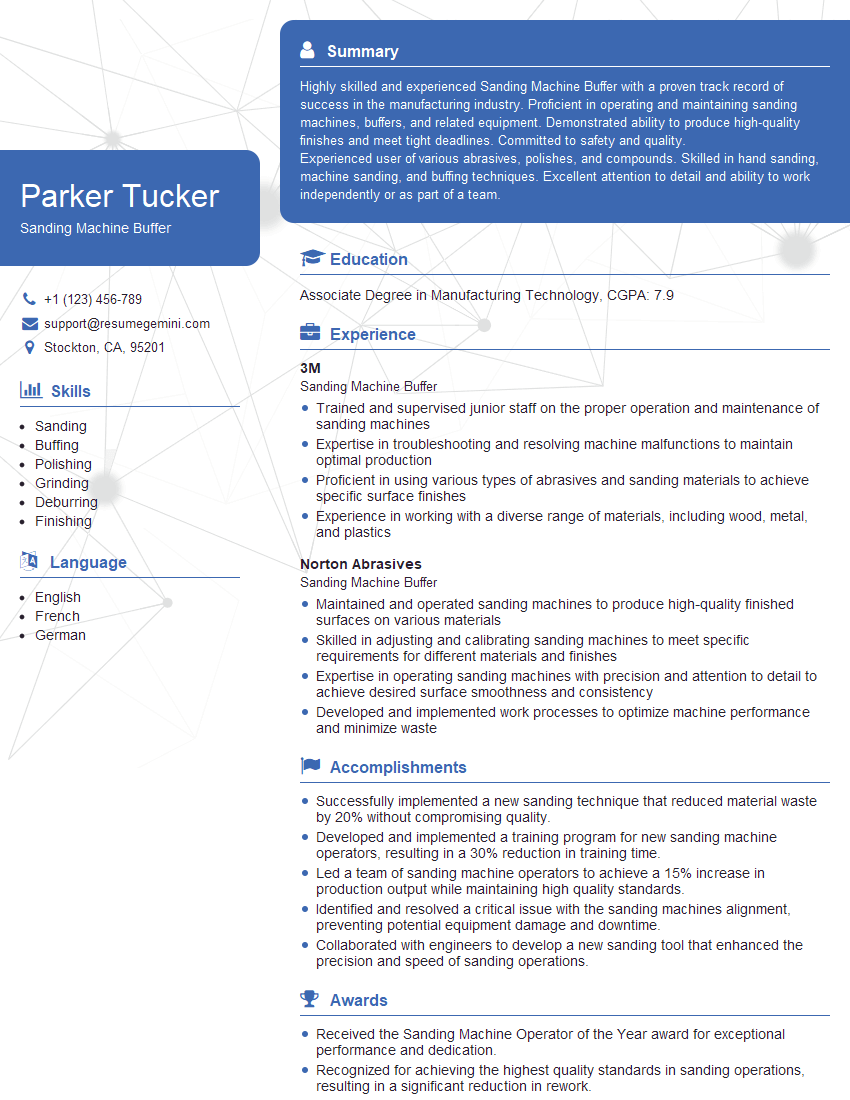

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sanding Machine Buffer

1. How do you determine the correct grit size for a sanding machine buffer?

To determine the correct grit size, I would consider the following factors:

- Material being sanded: Different materials have different hardness and require different grit sizes to achieve the desired finish.

- Desired finish: For a coarser finish, a lower grit size is used, while a finer finish requires a higher grit size.

- Experience and manufacturer recommendations: I would refer to the manufacturer’s guide and my own experience to select the appropriate grit size for the specific application.

2. What are the different types of sanding machine buffers and their applications?

There are generally two main types of sanding machine buffers:

Random Orbital Buffers

- Used for general sanding tasks, such as rough shaping, removing rust, and preparing surfaces for painting.

- Create a smooth, swirl-free finish.

Dual-Action Buffers

- Combine both rotating and orbiting motions for a more aggressive yet controlled sanding action.

- Ideal for removing imperfections, detailing, and polishing.

3. How do you maintain and troubleshoot a sanding machine buffer?

To maintain a sanding machine buffer, I would follow these steps:

- Regular cleaning: Removing dust and debris from the machine, especially from the ventilation vents and sanding pad.

- Checking components: Inspecting the power cord, hoses, and other components for any damage or wear.

- Lubrication: Following the manufacturer’s instructions for lubricating the machine’s moving parts.

4. What safety precautions should be taken when operating a sanding machine buffer?

To ensure safety when using a sanding machine buffer, I would adhere to the following precautions:

- Wearing appropriate PPE: Including a dust mask, safety glasses, and gloves.

- Proper ventilation: Working in a well-ventilated area to avoid inhaling sanding dust.

- Secure workpiece: Clamping or securing the workpiece firmly to prevent movement during sanding.

- Avoiding loose clothing: Wearing close-fitting clothing to avoid catching on the machine.

5. How do you achieve a consistent finish when using a sanding machine buffer?

To achieve a consistent finish, I would follow these techniques:

- Overlapping strokes: Sanding in even, overlapping strokes to prevent unevenness.

- Using a guide: Employing a sanding guide or jig to ensure consistent pressure and motion.

- Checking regularly: Frequently inspecting the sanded surface to monitor progress and make adjustments as needed.

6. What are some common mistakes to avoid when using a sanding machine buffer and how to prevent them?

Common mistakes and preventive measures include:

- Applying too much pressure: Can cause gouges or uneven sanding. Use less pressure and let the machine do the work.

- Sanding in one direction: Creates visible sanding marks. Sand in circular or overlapping motions for a smoother finish.

- Using the wrong grit: Can result in inefficient sanding or surface damage. Choose the appropriate grit size for the material and desired finish.

7. How do you handle delicate or intricate surfaces when using a sanding machine buffer?

When dealing with delicate surfaces, I would:

- Use a finer grit: To minimize material removal and prevent damage.

- Apply light pressure: To avoid gouging or scratching the surface.

- Use a backing pad: To cushion the sanding pad and provide support for the workpiece.

8. What techniques do you use to blend and smooth out transitions when sanding?

To blend and smooth out transitions, I employ techniques such as:

- Feathering: Gradually reducing the sanding pressure as I approach the transition.

- Overlapping strokes: Sanding in overlapping motions to create a smooth, even surface.

- Using a sanding block or foam pad: To help distribute pressure and prevent sharp transitions.

9. How do you inspect a sanded surface to ensure quality and identify any potential issues?

To inspect a sanded surface, I would:

- Check for smoothness: Run my hand or a fine-grit sandpaper over the surface to feel for any unevenness.

- Examine under lighting: Hold the workpiece under a bright light to identify any scratches or blemishes.

- Use a gauge or micrometer: For precision measurements to ensure that the surface meets the desired dimensions.

10. How do you work effectively as part of a team in a production environment?

In a team setting, I would:

- Communicate clearly: Share information, updates, and any concerns with my teammates.

- Cooperate and support: Assist colleagues when needed and contribute to the team’s success.

- Follow instructions: Adhere to the team lead’s directions and maintain a high level of quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sanding Machine Buffer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sanding Machine Buffer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Sanding Machine Buffer is responsible for smoothing and polishing surfaces using sanding machines and buffers. Their key job responsibilities include:1. Surface Preparation

Prior to sanding, they prepare surfaces by removing dirt, grease, and other contaminants.

- Cleaning surfaces with detergents and solvents.

- Removing old paint, varnish, or coatings.

- Filling holes and cracks with putty or wood filler.

2. Sanding and Buffing

They use sanding machines and buffers to smooth and polish surfaces to achieve the desired finish.

- Selecting the appropriate sandpaper or buffing pads based on the surface and desired result.

- Operating sanding machines or buffers with precision to achieve a uniform finish.

- Inspecting surfaces after sanding and buffing to ensure they meet specifications.

3. Equipment Maintenance

They maintain the sanding machines and buffers to ensure they are functioning properly.

- Cleaning and lubricating equipment regularly.

- Replacing worn or damaged parts.

- Conducting basic repairs and troubleshooting equipment issues.

4. Safety and Cleanliness

They follow safety protocols and maintain a clean work environment.

- Wearing appropriate personal protective equipment (PPE) while operating machinery.

- Ensuring the work area is well-ventilated and free from dust and debris.

- Disposing of hazardous materials in accordance with regulations.

Interview Tips

To prepare for a Sanding Machine Buffer interview and ace it, candidates can follow these tips:1. Research the Company and Position

Familiarize yourself with the company’s history, values, and the specific requirements of the position.

- Review the job description thoroughly to understand the key responsibilities and qualifications.

- Visit the company’s website and social media platforms to learn about their culture and recent developments.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are most relevant to the job. Quantify your accomplishments whenever possible using specific examples.

- Describe your past experience in sanding, buffing, and surface preparation.

- Provide instances where you successfully used sanding machines or buffers to achieve a high-quality finish.

- Mention any training or certifications you have in sanding or buffing techniques.

3. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses that showcase your strengths.

- Explain your experience in operating sanding machines or buffers.

- Describe your knowledge of different types of abrasives and their uses.

- Discuss your understanding of surface preparation techniques.

- Explain how you ensure safety and maintain a clean work environment while operating sanding machines.

4. Ask Meaningful Questions

Asking well-thought-out questions shows your interest in the position and the company.

- Inquire about the company’s quality standards and expectations for surface finishes.

- Ask about opportunities for professional development and training.

- Show your enthusiasm for the role and how your skills can contribute to the team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sanding Machine Buffer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!