Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Sanding Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

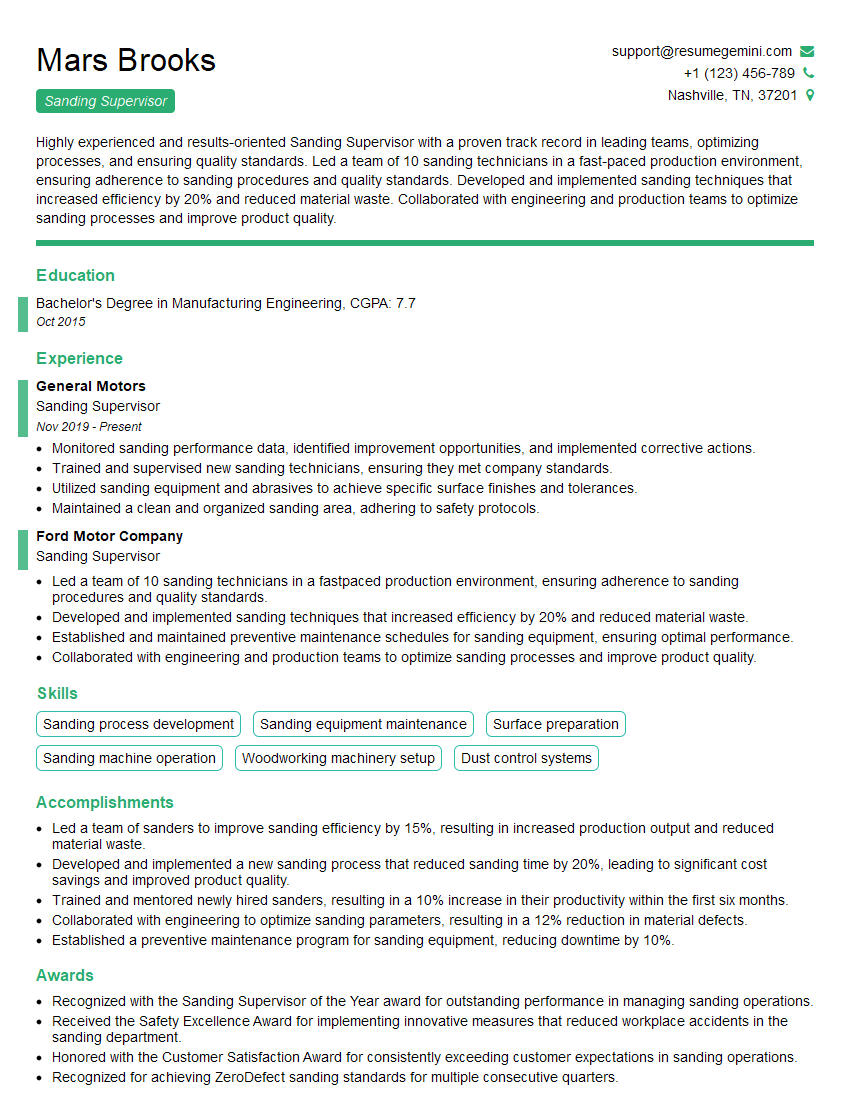

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sanding Supervisor

1. What are the different types of sanding machines used in the industry?

- Belt sanders: These machines use a continuous loop of sandpaper that moves rapidly over a flat or curved surface, providing a smooth finish.

- Orbital sanders: These machines use a circular motion to sand surfaces, resulting in a swirl-free finish.

- Random orbital sanders: Similar to orbital sanders, but with a random motion that helps to eliminate swirl marks and provide a more even finish.

- Disc sanders: These machines use a rotating disc covered in sandpaper to sand flat surfaces quickly and efficiently.

- Hand-held sanders: These small, portable machines are used for sanding small areas or detailed work.

2. What factors should be considered when selecting the appropriate sanding machine for a particular task?

Factors to Consider

- Surface type and material: Different surfaces require different sanding techniques and abrasives.

- Desired finish: The type of sanding machine used will determine the quality of the finish achieved.

- Efficiency and speed: Consider the size of the surface and the time available for sanding.

- Ergonomics: Choose a machine that is comfortable to use and minimizes operator fatigue.

- Safety features: Look for machines with safety features such as dust collection systems and vibration control.

3. What are the proper techniques for using sanding machines to achieve the desired results?

- Use the correct grit of sandpaper for the material being sanded.

- Move the sander in a consistent motion, applying even pressure throughout.

- Sand with the grain of the wood to avoid surface damage.

- Use a dust collection system to minimize dust inhalation and maintain a clean work environment.

- Inspect the surface regularly to ensure the desired finish is achieved.

4. How do you ensure the quality of sanding operations and meet customer specifications?

- Establish clear sanding standards and specifications.

- Provide comprehensive training to operators on proper techniques.

- Regularly calibrate and maintain sanding machines to ensure accuracy.

- Implement quality control measures, such as surface inspections and finish testing.

- Seek customer feedback and make adjustments as needed to improve quality.

5. How do you manage a team of sanders and maintain productivity while ensuring safety?

- Provide clear instructions and expectations to team members.

- Monitor progress and provide regular feedback.

- Address safety concerns promptly and enforce safety protocols.

- Foster a positive and collaborative work environment.

- Recognize and reward high performance.

6. What maintenance procedures are essential to ensure the longevity and optimal performance of sanding machines?

- Regularly clean and inspect sanding machines.

- Replace worn or damaged parts promptly.

- Lubricate moving parts as per manufacturer’s instructions.

- Check and adjust belts, discs, and other components for proper alignment and tension.

- Store machines in a dry and well-ventilated location.

7. How do you stay updated on the latest sanding technologies and best practices?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Network with other professionals in the field.

- Seek training and certification from equipment manufacturers.

- Stay informed about new sanding techniques and materials.

8. What are some common challenges faced in sanding operations and how do you mitigate them?

- Surface defects: Inspect surfaces carefully and use appropriate sanding techniques to minimize scratches or unevenness.

- Dust generation: Implement effective dust collection systems and provide personal protective equipment to operators.

- Operator fatigue: Provide ergonomic workstations and encourage regular breaks to prevent discomfort and injuries.

- Machine breakdowns: Establish a regular maintenance schedule and keep spare parts on hand to minimize downtime.

- Quality variations: Implement quality control measures and provide consistent training to ensure consistent results.

9. How do you prioritize sanding tasks and allocate resources efficiently?

- Establish clear priorities based on customer needs and deadlines.

- Assess the workload and available resources.

- Assign tasks to team members based on their skills and availability.

- Monitor progress and make adjustments as needed to ensure timely completion.

- Communicate effectively with team members and customers to manage expectations.

10. How do you handle customer complaints related to sanding operations?

- Listen attentively to customer concerns.

- Inspect the affected surface and identify the issue.

- Explain the cause of the problem and propose a solution.

- Take immediate action to rectify the issue and meet customer expectations.

- Document the complaint and follow up to ensure customer satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sanding Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sanding Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Sanding Supervisor is responsible for overseeing all aspects of the sanding process in a manufacturing or construction setting. They ensure that all sanding operations are carried out efficiently and according to specifications, while maintaining a safe and productive work environment.

1. Production Management

Supervises and coordinates sanding operations to meet production schedules and quality standards.

- Plans and assigns work to sanding team members, ensuring efficient use of resources.

- Monitors progress, identifies bottlenecks, and takes corrective actions to optimize productivity.

2. Quality Control

Inspects sanded surfaces to ensure they meet specified roughness, texture, and finish requirements.

- Develops and implements quality control procedures to maintain consistent standards.

- Identifies and corrects any defects or non-conformances in the sanding process.

3. Equipment Maintenance and Calibration

Ensures that sanding equipment is properly maintained, calibrated, and operated.

- Inspects and performs routine maintenance on sanding machines, tools, and accessories.

- Calibrates sanding equipment to ensure accurate and consistent results.

4. Safety and Compliance

Promotes a safe and compliant work environment in accordance with industry regulations.

- Enforces safety protocols and provides training to sanding team members.

- Ensures compliance with environmental regulations related to dust and emissions control.

Interview Tips

Preparing for an interview for a Sanding Supervisor position requires thorough research and thoughtful consideration of your skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s history, products or services, and industry standing. Thoroughly review the job description to understand the specific responsibilities and requirements of the Sanding Supervisor role.

- Visit the company website and social media pages to gather information about their culture and values.

- Reach out to your network or online platforms like LinkedIn to connect with current or former employees for insights into the company and role.

2. Highlight Relevant Skills and Experience

Tailor your resume and interview responses to showcase your relevant skills and experience in sanding operations, quality control, equipment maintenance, and safety management. Provide specific examples that demonstrate your abilities and achievements.

- Quantify your accomplishments using metrics or data whenever possible, such as “Reduced sanding defects by 25% through implementing a new quality control process.”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing a clear and compelling narrative of your experiences.

3. Practice Your Answers

Prepare for common interview questions related to sanding supervision, quality management, and safety. Practice your answers aloud or with a mock interviewer to improve your delivery and confidence.

- Anticipate questions about your experience in managing sanding teams, ensuring quality standards, troubleshooting equipment issues, and maintaining a safe work environment.

- Prepare examples of your problem-solving abilities, decision-making processes, and leadership qualities.

4. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive at the interview on time. This demonstrates respect for the interviewer’s time and conveys a sense of professionalism and organization.

- Choose attire that is appropriate for the company culture and industry setting.

- Plan your route and allow ample time for unexpected delays.

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions that show your interest in the position and company. This is an opportunity to clarify any details, express your enthusiasm, and leave a lasting impression.

- Ask about the company’s growth plans, industry trends, or specific challenges the Sanding Supervisor role is expected to address.

- Inquire about opportunities for professional development and advancement within the organization.

Next Step:

Now that you’re armed with the knowledge of Sanding Supervisor interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Sanding Supervisor positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini